Abstract

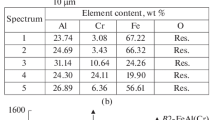

High-temperature air oxidation (up to 1100°C) of detonation coatings made of NiAl intermetallide and eutectic (β-NiAl + γ-Re) alloys is examined with x-ray diffraction and electron microscopy. A substantial difference between the air oxidation mechanisms of these coatings is revealed. The key factor that governs the air oxidation of these coatings is the ratio between rates at which aluminum and nickel oxides are formed.

Similar content being viewed by others

References

M. B. Henderson, J. Hannis, G. McColvin, and G. Ogle, “Materials issues for the design of industrial gas turbines,” in: G. Fuchs et al. (eds), Advanced Materials and Processes for Gas Turbines, The Minerals, Metals & Materials Society, Warrendale, Pennsylvania (2003), pp. 3–13.

G G. L. Ericson, “The development and application of CMSX-10,” in: R. D. Kissinger et al. (eds.), Superalloys 1996, The Minerals, Metals & Materials Society, Warrendale, Pennsylvania (1996), pp. 35–44.

W. S. Walston, K. S. O’Hara, E. W. Ross, et al., “Rene N6: Third generation single crystal superalloy,” in: Superalloys 1996, The Minerals, Metals & Materials Society, Warrendale, Pennsylvania (1996), pp. 27–34.

Yu. M. Lakhtin, G. A. Slisarenko, A. N. Prudnikov, and B. S. Starokonev, “Powder Ni-Al intermetallide coatings,” Metalloved. Term. Obrab. Met., No. 9, 29–31 (1980).

Yu. A. Tamarin, Heat-Resistant Diffusion Coatings of Turbine Engine Blades [in Russian], Mashinostroenie, Moscow (1978), p. 136.

O. M. Barabash, M. Yu. Barabash, and V. E. Oliker, “Effect of rhenium on formation of the structure of eutectic alloys based on β-NiAl + γ-Re,” Powder Metall. Met. Ceram., 42, No. 3–4, 180–183 (2003).

V. E. Oliker, M. Yu. Barabash, E. F. Grechishkin, et al., “Mechanical properties of eutectic alloys β-NiAl + γ-Re and spray coatings,” Powder Metall. Met. Ceram., 45, No. 3–4, 173–180 (2006).

M. Reid, M. J. Pomeroy, and J. S. Robinson, “Microstructural stability of a Ni-Pt-Al coating on CMSX-10 alloy at 950–1000°C,” Mater. High Temperatures, 20, No. 4, 467–474 (2003).

J. Doychak, J. L. Smialek, and T. E. Mitchell, “Transient oxidation of single-crystal beta-NiAl, ” Metall Trans., 20A, 499–518 (1989).

H. Svensson, J. Angenete, K. Stiller, and V. Langer, “Microstructural studies of NiAl-based model alloys and commercial coatings after isothermal oxidation,” Mater. High Temper., 20, No. 3, 421–427 (2001).

A. Y. Lozovoi, A. Alavi, and M. W. Finnis, “Surface stoichiometry and the initial oxidation of NiAl (110),” Phys. Rev. Let., 85, No. 3, 610–613 (2003).

M. Kh. Karapet’yants and M. L. Karapet’yants, Basic Thermodynamic Constants for Inorganic and Organic Substances [in Russian], Khimiya, Moscow (1968), p. 472.

M. P. Arbuzov and V. G. Chuprina, “X-ray diffraction study of the oxidation of Ni3(Al, Ti) alloys,” Powder Metall. Met. Ceram., 14, No. 7, 572–575 (1975).

L. G. Reiter, Chemistry for Metallurgists. Properties of Important Elements: Handbook, Kiev (1995), p. 139.

B. A. Pint, J. A. Haynes, K. L. More, et al., “Composition effects on aluminide oxidation performance: Objectives for improved bond coats,” in: T. M. Pollock, R. D. Kissinger, et al. (eds.), Superalloys 2000, TMS, Warrendale, Pennsylvania (2000), pp. 629–638.

C. L. Fu, M. H. Yoo, and K. M. Ho, “Equilibrium point defects in intermetallics with the B2 structure: NiAl and FeAl,” Phys. Rev., 48. 6712–6715 (1993).

Y. Mishin and D. Fakas, “Atomistic simulation of point defects and diffusion in B2NiAl,” Scripta Mat., 39, No. 4–5, 625–630 (1998).

O. Kubaschewski and B. E. Hopkins, Oxidation of Metals and Alloys, Butterworths, London (1962).

E. T. Denisenko and Yu. A. Panfilov, “Oxidation of porous bodies,” Powder Metall. Met. Ceram., 5, No. 10, 799–801 (1966).

Author information

Authors and Affiliations

Additional information

__________

Translated from Poroshkovaya Metallurgiya, Vol. 46, No. 3–4 (454), pp. 86–95, 2007.

Rights and permissions

About this article

Cite this article

Oliker, V.E., Barabash, M.Y., Grechishkin, E.F. et al. High-temperature air oxidation of coatings based on eutectic (β-NiAl + γ-Re) alloys and NiAl intermetallide. Powder Metall Met Ceram 46, 175–181 (2007). https://doi.org/10.1007/s11106-007-0028-2

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11106-007-0028-2