ABSTRACT

Purpose

A new dry powder inhalation technology creates inhalable particles from a coherent lyophilized bulk at the time of inhalation. The aim of this study was to evaluate several approaches to improve the fine particle fraction (FPF) and to understand underlying mechanisms.

Methods

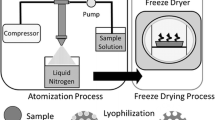

Lysozyme was chosen as model drug. Phenylalanine and valine were added, and the freezing process was varied. Lyophilisate characteristics as well as aerosolization behavior was analyzed.

Results

The addition of the crystalline amino acids rendered a dose independent three-fold increase of the FPF. This is possibly due to enhanced fracture properties of the lyophilisates upon impact of the air stream and reduced particle agglomeration/cohesion caused by a rougher surface. This positive effect was well preserved over 3 months of storage. The structure of the lyophilisate was influenced by the freezing process which in turn affected the aerosolization behavior. Liquid nitrogen and vacuum-induced freezing performed best, doubling the FPF. The special cake morphology with elongated channels enabled easy disintegration. The resulting large porous particles comprise a low density being advantageous for a high FPF.

Conclusion

The variation of the lyophilization process and formulation utilizing excipients enabled an optimization of the FPF of the novel lyophilisate based DPI system.

Similar content being viewed by others

Abbreviations

- ACI:

-

Andersen Cascade Impactor

- API:

-

active pharmaceutical ingredient

- DPI:

-

dry powder inhaler

- ED:

-

emitted dose

- FPF:

-

fine particle fraction

- Lys:

-

lysozyme

- MD:

-

metered dose

- Phe:

-

L-phenylalanine

- RH:

-

relative humidity

- SEM:

-

scanning electron microscopy

- Tg′:

-

glass transition temperature of the max. freeze concentrated solution

- Val:

-

L-valine

- XRD:

-

x-ray diffractometry

REFERENCES

Newman SP, Busse WW. Evolution of dry powder inhaler design, formulation, and performance. Respir Med. 2002;96:293–304.

Frijlink HW, De Boer AH. Dry powder inhalers for pulmonary drug delivery. Expert Opin Drug Deliv. 2004;1:67–86.

Newhouse MT, Nantel NP, Chambers CB, Pratt B, Parry-Billings M. Clickhaler (a novel dry powder inhaler) provides similar bronchodilation to pressurized metered-dose inhaler, even at low flow rates. Chest. 1999;115:952–6.

Pitcairn GR, Lankinen T, Seppälä O-P, Newman SP. Pulmonary drug delivery from the Taifun dry powder inhaler is relatively independent of the patient’s inspiratory effort. J Aerosol Med. 2000;13:97–104.

Islam N, Gladki E. Dry powder inhalers (DPIs)—a review of device reliability and innovation. Int J Pharm. 2008;360:1–11.

Tobyn M, Staniforth JN, Morton D, Harmer Q, Newton ME. Active and intelligent inhaler device development. Int J Pharm. 2004;277:31–7.

Owens DR, Zinman B, Bolli G. Alternative routes of insulin delivery. Diabetic Med. 2003;20:886–98.

Chew NYK, Chan H-K. The role of particle properties in pharmaceutical powder inhalation formulations. J Aerosol Med. 2002;15:325–30.

Chow A, Tong H, Chattopadhyay P, Shekunov B. Particle engineering for pulmonary drug delivery. Pharm Res. 2007;24:411–37.

Yamashita C, Akagi A, Fukunaga Y. Dry powder inhalation system for transpulmonary administration, United States Patent 7735485 2010.

Franks F. Freeze-drying of bioproducts: putting principles into practice. Eur J Pharm Biopharm. 1998;45:221–9.

Claus S, Schoenbrodt T, Weiler C, Friess W. Novel dry powder inhalation system based on dispersion of lyophilisates. Eur J Pharm Sci. 2011;43:32–40.

Hottot A, Vessot S, Andrieu J. Freeze drying of pharmaceuticals in vials: influence of freezing protocol and sample configuration on ice morphology and freeze-dried cake texture. Chem Eng Process. 2007;46:666–74.

Liu J. Physical characterization of pharmaceutical formulations in frozen and freeze-dried solid states: techniques and applications in freeze-drying development. Pharm Dev Technol. 2006;11:3–28.

Kasper JC, Friess W. The freezing step in lyophilization: physico-chemical fundamentals, freezing methods and consequences on process performance and quality attributes of biopharmaceuticals. Eur J Pharm Biopharm. 2011;78:248–63.

Patapoff TW, Overcashier DE. The importance of freezing on lyophilization cycle development. BioPharm Int. 2002;72:16–21.

Searles JA, Carpenter JF, Randolph TW. The ice nucleation temperature determines the primary drying rate of lyophilization for samples frozen on a temperature-controlled shelf. J Pharm Sci. 2001;90:860–71.

Liu J, Viverette T, Virgin M, Anderson M, Dalal P. A study of the impact of freezing on the lyophilization of a concentrated formulation with a high fill depth. Pharm Dev Technol. 2005;10:261–72.

Webb SD, Cleland JL, Carpenter JF, Randolph TW. Effects of annealing lyophilized and spray-lyophilized formulations of recombinant human interferon-γ. J Pharm Sci. 2003;92:715–29.

Ulubayram K, Eroglu I, Hasirci N. Gelatin microspheres and sponges for delivery of macromolecules. J Biomater Appl. 2002;16:227–41.

United States Pharmacopeia 36 Chapter 601—Physical tests and determinations: aerosols, nasal sprays, metered-dose inhalers, and dry powder inhalers, vol. 36. United States Pharmacopoial Convention Inc. 2012.

Tang X, Pikal M. Design of freeze-drying processes for pharmaceuticals: practical advice. Pharm Res. 2004;21:191–200.

Pikal MJ, Shah S. Moisture transfer from stopper to product and resulting stability implications. Dev Biol Stand. 1992;74:165–77. discussion 177–169.

Mattern M, Winter G, Kohnert U, Lee G. Formulation of proteins in vacuum-dried glasses. II. Process and storage stability in sugar-free amino acid systems. Pharm Dev Technol. 1999;4:199–208.

Akers MJ, Milton N, Byrn SR, Nail SL. Glycine crystallization during freezing: the effects of salt form, pH, and ionic strength. Pharm Res. 1995;12:1457–61.

Franks F, Auffret T. Freeze-drying of pharmaceuticals and biopharmaceuticals. Cambridge: RSC; 2007.

Chatterjee K, Shalaev EY, Suryanarayanan R. Partially crystalline systems in lyophilization: I Use of ternary state diagrams to determine extent of crystallization of bulking agent. J Pharm Sci. 2005;94:798–808.

Mohan R, Koo K-K, Strege C, Myerson AS. Effect of additives on the transformation behavior of l-phenylalanine in aqueous solution. Ind Eng Chem Res. 2001;40:6111–7.

Roth C, Winter G, Lee G. Continuous measurement of drying rate of crystalline and amorphous systems during freeze-drying using an in situ microbalance technique. J Pharm Sci. 2001;90:1345–55.

French DL, Edwards DA, Niven RW. The influence of formulation on emission, deaggregation and deposition of dry powders for inhalation. J Aerosol Sci. 1996;27:769–83.

Weiler C, Egen M, Trunk M, Langguth P. Force control and powder dispersibility of spray dried particles for inhalation. J Pharm Sci. 2010;99:303–16.

Stability Testing of New Drug Substances and Products Q1A(R2), International Confernece on Harmonisation of technical requirements for registration of pharmaceuticals for human use 2003.

Kasper JC, Schaffert D, Ogris M, Wagner E, Friess W. Development of a lyophilized plasmid/LPEI polyplex formulation with long-term stability—a step closer from promising technology to application. J Control Release. 2011;151:246–55.

Roos Y, Karel M. Plasticizing effect of water on thermal behavior and crystallization of amorphous food models. J Food Sci. 1991;56:38–43.

Searles JA. Freezing and annealing phenomena in lyophilization. In: Rey L, May JC, editors. Freeze-drying/lyophilization of pharmaceutical and biological products. New York: Marcel Dekker, Inc.; 2004.

Hsu CC, Nguyen HM, Yeung DA, Brooks DA, Koe GS, Bewley TA, et al. Surface denaturation at solid-void interface—a possible pathway by which opalescent participates form during the storage of lyophilized tissue-type plasminogen activator at high temperatures. Pharm Res. 1995;12:69–77.

Vanbever R, Mintzes JD, Wang J, Nice J, Chen D, Batycky R, et al. Formulation and physical characterization of large porous particles for inhalation. Pharm Res. 1999;16:1735–42.

Chang BS, Kendrick BS, Carpenter JF. Surface-induced denaturation of proteins during freezing and its inhibition by surfactants. J Pharm Sci. 1996;85:1325–30.

ACKNOWLEDGMENTS AND DISCLOSURES

This research project is supported by Boehringer Ingelheim Pharma GmbH & Co. KG. We thank Holger Holakovsky and Gilbert Wuttke for the possibility to do the high speed camera recordings. We also thank Alexandra Pickel for her analytical contribution to this study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Claus, S., Weiler, C., Schiewe, J. et al. Optimization of the Fine Particle Fraction of a Lyophilized Lysozyme Formulation for Dry Powder Inhalation. Pharm Res 30, 1698–1713 (2013). https://doi.org/10.1007/s11095-013-1015-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-013-1015-6