Abstract

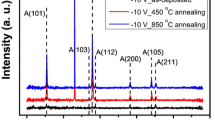

Three deposition modes of red atmospheric pressure plasma enhanced chemical vapor deposition were applied to study the influences of plasma discharge and the external substrate temperature on improving its crystallization: deposition in plasma red zone with post-heat annealing [Mode (a)], deposition outside plasma zone with a heated substrate [Mode (b)] and deposition inside plasma zone with a heated substrate [Mode (c)]. \(\hbox {TiO}_2\) film obtained with Mode (c) is anatase and the other two are amorphous. Four more substrate temperatures (100 \({^{\circ }}\)C, 200 \({^{\circ }}\)C, 300 \({^{\circ }}\)C, 400 \({^{\circ }}\)C) were investigated in Mode(c). The OES peaks of Ti excited atomic state shows out in Mode (c) and their intensity increases with the substrate temperature. The crystalline degree increases and the structure becomes more compact with the substrate temperature. The film obtained at 400 \({^{\circ }}\)C presented the highest photocatalytic activity.

Similar content being viewed by others

References

Shi JJ, Kong MG (2006) Phys Rev Lett 96:105009

Mai-Prochnow A, Murphy AB, McLean KM, Kong MG, (Ken) Ostrikov K (2014) Int J Antimicrob Agents 43:508–517

Lisco F, Shaw A, Wright A, Walls JM, Iza F (2017) Solar Energy 146:287–297

Jiang N, Hu J, Li J, Shang K, Lu N, Wu Y (2015) Appl Catal B: Environ 184:355–363

Pekárek S, Mikeš J, Beshajovà I, Pelikánová F, Krčma P, Dzik (2016) Plasma Chem Plasma Process 36:1187–1200

Massines F, Sarra-Bournet C, Fanelli F, Naudé N, Gherardi N (2012) Plasma Process Polym 9:1041–1073

Klenko Y, Pichal J (2012) Plasma Chem Plasma Process 32:1215–1225

Fujishima A, Honda K (1972) Nature 238:37–38

O’Regan B, Grätzel M (1991) Nature 353:737–740

Villatte G, Massard C, Descamps S, Sibaud Y, Forestier C, Awitor KO (2015) Int J Nanomed 10:3367–3375

Sun Q, Xu Y (2010) J Phys Chem C 114:18911–18918

Zhang X, Fujishima A, Jin M, Emeline AV, Murakami T (2006) J Phys Chem B 110:25142–25148

Maeda M, Watanabe T (2005) Thin Solid Films 489:320–324

Zhou W, Zhong X, Wu X, Yuan L, Shu Q, Li W, Xia Y (2007) J Phys D: Appl Phys 40:219–226

Chen Q, Liu Q, Hubert J, Huang W, Baert K, Wallaert G, Terryn H, Delplancke-Ogletree Marie-Paule, Reniers F (2017) Surf Coat Technol 310:173–179

Collette S, Hubert J, Batan A, Baert K, Raes M, Vandendael I, Daniel A, Archambeau C, Terryn H, Reniers F (2016) Surf Coat Technol 289:172–178

Di L, Shi C, Li X, Liu J, Zhu A (2012) Chem Vap Depos 18:309–314

Bazinette Rémy, Paillol Jean, Lelièvre Jean-François, Massines Françoise (2016) Plasma Process. Polym. 13:1015–1024

Wang D, Yang Q, Guo Y, Liu X, Shi J, Zhang J (2011) Mater Lett 65:2526–2529

Gazal Y, Dublanche-Tixier C, Chazelas C, Colas M, Carles P, Tristant P (2016) Thin Soild Film 600:43–52

Maurau R, Boscher ND, Olivier S, Bulou S, Belmonte T, Dutroncy J, Sindzingre T, Choquet P (2013) Surf Coat Technol 232:159–165

Sarra-Bournet C, Charles C, Boswell R (2011) Surf Coat Technol 205:3939–3946

Hodgkinson JL, Sheel DW (2013) Surf Coat Technol 230:73–76

Busani T, Devine RAB (2008) Semicond Sci Technol 20:870–875

Granier A, Begou T, Makaoui K, Soussou A, Gaviot Bruno Bêche E, Besland Marie-Paule, Goullet A (2009) Plasma Process Polym 6:S741–S745

van Gessel B, Brandenburg R, Bruggeman P (2013) Appl Phys Lett 103:064103

Gazal Y, Chazelas C, Dublanche-Tixier C, Tristant P (2017) J Appl Phys 121:123301

Acayanka E, Djowe AT, Laminsi S, Tchoumkwè CC, Nzali S, Mbouopda AP, Ndifon PT, Gaigneaux EM (2013) Plasma Chem Plasma Process 33:725–735

Zhang J, Li M, Feng Z, Chen J, Li C (2006) J Phys Chem B 110:927–935

Frenck HJ, Kulisch W, Kuhr M, Kassing R (1991) Thin Solid Films 201:327–335

Yasuda H, Wang CR (1985) J Polym Sci Polym Chem Ed 23:87–106

Smith Donald L (1995) Thin-film deposition Princiles and practice. McGraw-Hill, New York

Boumerzoug M, Pang Z, Boudreau M, Mascher P, Simmons JG (1995) Appl Phys Lett 66:302–304

Forsberg P (1991) Physica Scripta 44:446–476

Ding K, Lieberman MA, Lichtenberg AJ (2014) J Phys D Appl Phys 47:305203

Ding K, Lieberman MA, Lichtenberg AJ, Shi JJ, Zhang J (2014) Plasma Sources Sci Technol 23:065048

Norlén G (1973) Physica Scripta 8:249–268

Seo HK, Elliott CM, Shin HS (2010) Appl Mater Interfaces 2(12):3397–3400

Zhang XW, Han GR (2008) Thin Solid Films 516:6140–6144

Xia B, Li W, Zhang B, Xie Y (1999) J Mater Sci 34:3505–3511

Cordero T, Chovelon J, Duchamp C, Ferronato C, Matos J (2007) Appl Catal B Environ 73:227–235

Acknowledgements

The authors are grateful to the Nature Science Foundation of China (Nos. 10835004, 11375042, 11475043 and 11875104).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations

Rights and permissions

About this article

Cite this article

Xu, Y., Zhang, Y., Li, L. et al. Synergistic Effect of Plasma Discharge and Substrate Temperature in Improving the Crystallization of \(\hbox {TiO}_2\) Film by Atmospheric Pressure Plasma Enhanced Chemical Vapor Deposition. Plasma Chem Plasma Process 39, 937–947 (2019). https://doi.org/10.1007/s11090-019-09961-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11090-019-09961-0