Abstract

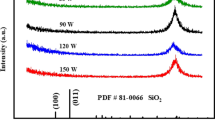

Fine particles were modified with a thin film of SnO2 by using a barrel sputtering system that is a dry process. The conditions for the preparation of SnO2 were studied by reactive sputtering onto a glass plate substrate. The optimal conditions for the preparation of tetragonal SnO2 were identified as 60% partial oxygen pressure and 1.0 Pa total gas pressure with the substrate at room temperature. Under the optimized conditions, the surfaces of Al flake particles were modified with a thin film of SnO2. XRD and SEM/EDS analysis of the prepared samples showed that the Al particle surfaces were uniformly modified by a thin film of SnO2 in all cases. The film thicknesses were 80, 130, and 180 nm at RF outputs of 195, 350, and 490 W. These measured thicknesses coincided with the values estimated from the interference colors of the samples.

Similar content being viewed by others

References

Iinoya K, Gotho K, Hogashitani K (eds) (1991) Powder technology handbook, Mercel Dekker Inc

Cairns JA, Nelson RS, Barnfield RW (1976) GB Patent 1455248

Schilf HW, Heuberger M, Frey F, Jehn HA, Telle R, Raub CJ (1991) Mat Sci Eng A 139:185

Muller HR, Ensinger W, Frech G, Wolf GK (1994) Nucl Instr and Meth B 89:357

Ensinger W (1999) Nucl Instr and Meth B 148:17

Ensinger W, Muller HR (1998) Nucl Instr and Meth B 141:693

Ensinger W, Muller HR (2003) Surf Coat Technol 163–164:281

Takeshima E (1996) JP Patent 02-153068

Takeshima E, Gonoi K, Sirokura T, Kawakami H (1996) JP Patent 08-081753

Hara M, Hatano Y, Abe T, Watanabe K, Naitoh T, Ikeno S, Honda Y (2003) J Nucl Mater 320:265

Abe T, Akamaru S, Watanabe K (2004) J Alloys Compd 377:194

Abe T, Akamaru S, Watanabe K, Honda Y (2005) J Alloys Compd 402:227

Fitzpatrick LE (ed) (1992) Encyclopedia of materials characterization: Surface, interface, thin films, Butterworth-Heinemann

Snyders R, Wautelet M, Gouttebaron R, Dauchot JP, Hecq M (2001) Surf Coat Tech 142–144:187

Snyders R, Wautelet M, Gouttebaron R, Dauchot JP, Hecq M (2003) Thin Solid Films 423:125

Snyders R, Gouttebaron R, Dauchot JP, Hecq M (2005) Surf Coat Tech 200:448

Chung JH, Choe YS, Kim DS (1999) Thin Solid Films 349:126

Ruske M, Brauer G, Pistner J, Pfafflin U, Szczyrbowski J (1999) Thin Solid Films 351:146

Liu PY, Chen JF, Sun WD (2004) Vacuum 76:7

Zhou ZB, Cui RQ, Pang QJ, Wang YD, Meng FY, Yu XB (2001) Appl Surf Sci 172:245

Acknowledgement

This work was partially supported by a Grant-in-aid for Science Research from Ministry of Education, Science, Sports and Culture in Japan.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abe, T., Higashide, S., Inoue, M. et al. Surface Modification of Fine Particles with a SnO2 Film by Using a Polyhedral-Barrel Sputtering System. Plasma Chem Plasma Process 27, 799–811 (2007). https://doi.org/10.1007/s11090-007-9100-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11090-007-9100-4