Abstract

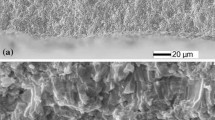

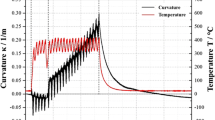

Molten particles in a thermal spray land on a rough surface, coalesce with each other and freeze to form a coating. Surface tension prevents liquid splats from completely filling crevices in the substrate, forming pores. An analytical model is developed to estimate the volume of such pores by calculating the equilibrium shape of a liquid meniscus pressing down on a surface asperity. Predictions from the model are compared with experimental results for the volume of voids formed under plasma sprayed yttria stabilised zirconia (YSZ) particles (average diameter 18 μm) landing with an average velocity of 250 m/s on patterned silicon surfaces that had vertical posts on them. The model predicted, to within an order-of-magnitude, the volume of voids on a surface in which the posts were tall (3 μm high) and closely spaced (1 μm apart), where pores were principally formed by incomplete filling of gaps.

Similar content being viewed by others

Abbreviations

- e :

-

length of meniscus

- g :

-

gravity acceleration

- h :

-

liquid height

- h s :

-

height of deformed liquid bottom

- i :

-

number of post, counting from point of droplet impact

- p :

-

pressure

- r :

-

radial direction

- R :

-

splat radius

- R a :

-

average surface roughness

- s :

-

theoretical height of deformed liquid surface of the underside of a splat

- V :

-

impact velocity

- V in :

-

Volume of incompletely filled voids

- x :

-

Cartesian coordinate

- y :

-

Cartesian coordinate

- z :

-

Cartesian coordinate

- α :

-

capillary length

- β :

-

radius of the surface asperities

- θ :

-

angle of perfect contact

- σ :

-

surface tension

- ρ :

-

liquid density

- \( \phi _{v} \) :

-

meniscus contact angle

- \( \phi _{t} \) :

-

meniscus contact angle

Reference

Knotek O, Elsing R (1987) Surf Coat Tech 32:261–271

Cirolini S, Harding JH, Jacucci G (1991) Surf Coat Tech 48:137–145

Ghafouri-Azar R, Mostaghimi J, Chandra S, Charmchi M (2003) J Therm Spray Tech 12:3–69

McPherson R, Shafer BV (1982) Thin Solid Films 97:201–204

Xue M, Chandra S, Mostaghimi J (2006) J Therm Spray Tech 15:531–536

Fukanuma H (1994) J Therm Spray Tech 3(1):33–44

Sobolev VV, Guilemany JM (1996) J Mater Letter 28:331–335

Cai WD, Lavernia EJ (1997) Mater Sci Eng A226–228:8–12

Heichal Y, Chandra S (2005) J Heat Transf 127:1269–1275

Timsit RS (1982) Wear 83:129–141

Pasandideh-Fard M, Chandra S, Mostaghimi J (2002) Int J Heat Mass Tran 45:2229–2242

Acknowledgement

The authors would like to acknowledge the support and assistance of GE Global Research Centre, NY, USA, in providing the patterned surfaces and FIB micrographs.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xue, M., Chandra, S., Mostaghimi, J. et al. Formation of Pores in Thermal Spray Coatings due to Incomplete Filling of Crevices in Patterned Surfaces. Plasma Chem Plasma Process 27, 647–657 (2007). https://doi.org/10.1007/s11090-007-9097-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11090-007-9097-8