Abstract

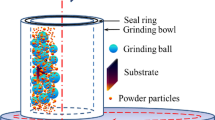

An Al–SiC coating was synthesized on Ti–6Al–4 V alloy substrate using the mechanical alloying method. The effects of annealing treatment on the microstructure, the microhardness, the friction and wear resistance and the high-temperature oxidation resistance of the coating were investigated. The results showed that the coating had a composite structure in which the reinforcing SiC particles were evenly dispersed in the Al matrix. Both the surface microhardness and the wear resistance of the substrate improved because of the as-synthesized coating. The oxidation resistance was enhanced because of the formation of an Al3Ti layer and a Ti5Si3-rich layer in the coating during oxidation. Specifically, the coating formed a tri-layer structure during thermal exposure due to the reaction in the coating and interdiffusion between the coating and the substrate. The outer layer had a complex structure, which was comprised of the Al–Si alloy as the matrix and the unevenly distributed SiC and Al4C3. This layer had low microhardness and tended to flake in both friction and oxidation processes. The inner layer was an Al3Ti layer, which had high microhardness and favorable wear resistance, and could protect the substrate from severe oxidation at elevated temperature. A Ti5Si3-rich interlayer between the inner layer and the substrate formed in the initial annealing process and could further retard the inward diffusion of oxygen during oxidation.

Similar content being viewed by others

References

C. Leyens and M. Peters, Titanium and Titanium Alloys, (Wiley, Weinheim, 2003).

A. S. Patil, V. D. Hiwarkar, P. K. Verma and R. K. Khatirkar, Effect of TiB2 addition on the microstructure and wear resistance of Ti-6Al-4 V alloy fabricated through direct metal laser sintering (DMLS). Journal of Alloys and Compounds777, 2019 (165).

K. Maeda, S. Suzuki, K. Ueda, T. Kitashima, S. K. Bhattacharya, R. Sahara and T. Narushima, Experimental and theoretical study of the effect of Si on the oxidative behavior of Ti–6Al–4 V alloys. Journal of Alloys and Compounds776, 2019 (519).

D. Tijo and M. Masanta, Mechanical performance of in situ TiC–TiB2 composite coating deposited on Ti–6Al–4 V alloy by powder suspension electro-discharge coating process. Surface and Coatings Technology328, 2017 (192).

D. T. Waghmare, C. K. Padhee, R. Prasad and M. Masanta, NiTi coating on Ti-6Al-4 V alloy by TIG cladding process for improvement of wear resistance: microstructure evolution and mechanical performances. Journal of Materials Processing Technology262, 2018 (551).

X. Li, J. Tian, W. Tian, X. Li and W. Xie, Oxidation resistant Ce-modified silicide coatings prepared on Ti–6Al–4 V alloy by pack cementation process. Oxidation of Metals89, 2018 (471).

Q. An, X. Cong, P. Shen and Q. Jiang, Roles of alloying elements in wetting of SiC by Al. Journal of Alloys and Compounds784, 2019 (1212).

H. Lee, J. H. Choi, M. C. Jo, D. Lee, S. Shin, I. Jo, S. Lee and S. Lee, Effects of SiC particulate size on dynamic compressive properties in 7075-T6 Al-SiCp composites. Materials Science and Engineering A738, 2018 (412).

C. Wu, T. Gao, Q. Sun, G. Liu, X. Du and X. Liu, A novel method of coating ex situ SiC particles with in situ SiC interlayer in Al-Si-C alloy. Journal of Alloys and Compounds754, 2018 (39).

A. Melaibari, A. Fathy, M. Mansouri and M. A. Eltaher, Experimental and numerical investigation on strengthening mechanisms of nanostructured Al-SiC composites. Journal of Alloys and Compounds774, 2019 (1123).

S. Mosleh-Shirazi, F. Akhlaghi and D. Li, Effect of SiC content on dry sliding wear, corrosion and corrosive wear of Al/SiC nanocomposites. Transactions of Nonferrous Metals Society of China26, 1801 (2016).

P. Rodrigo, M. Campo, B. Torres, M.D. Escalera, E. Otero, J. Rams, Microstructure and wear resistance of Al–SiC composites coatings on ZE41 magnesium alloy. Applied Surface Science255, 2009 (9174).

M. Moazami-Goudarzi, F. Akhlaghi, Wear behavior of Al 5252 alloy reinforced with micrometric and nanometric SiC particles. Tribology International102, 2016 (28).

T. Sritharana, L.S. Chana, L.K. Tana, N.P. Hung, A feature of the reaction between Al and SiC particles in an MMC. Materials Characterization47, 2001 (75).

C. Kawai, Effect of Interfacial Reaction on the thermal conductivity of Al–SiC composites with SiC dispersions. Journals of the American Ceramic Society84, 2001 (896).

Y. Yasutomi, J. Sawada, T. Kikuchi, K. Nakamura, Y. Manabe, K. Nagano, H. Kuroda, T. Sumi, H. Kubokawa, M. Nagai, H. Kogure, Y. Sawai, T. Kishi, Effects of the SiC/Al interface reaction on fracture behavior of a composite conductor using SiC fiber reinforced aluminum for next generation power equipment. Journal of Materials Science34, 1999 (1583).

S. Nouri, S. Rastegari, S. Mirdamadi, M. Hadavi, Microstructure and oxidation resistance of Si modified aluminide coating on TiAl based alloys. Surface Engineering31, 2014 (930).

J. Sun, J.S. Wu, B. Zhao, F. Wang, Microstructure, wear and high temperature oxidation resistance of nitrided TiAl based alloys. Materials Science and Engineering A329–331, 2002 (713).

Z.G. Zhang, Y.P. Peng, Y.L. Mao, C.J. Pang, L.Y. Lu, Effect of hot-dip aluminizing on the oxidation resistance of Ti–6Al–4 V alloy at high temperatures. Corrosion Science55, 2012 (187).

S.C. Jeng, Oxidation behavior and microstructural evolution of hot-dipped aluminum coating on Ti–6Al–4 V alloy at 800°C. Surface and Coatings Technology235, 2013 (867).

W. Gu, Bulk Al/SiC nanocomposite prepared by ball milling and hot pressing method. Transactions of Nonferrous Metals Society of China16, 2006 (s398).

A. Hassani, E. Bagherpour, F. Qods, Influence of pores on workability of porous Al/SiC composites fabricated through powder metallurgy + mechanical alloying. Journal of Alloys and Compounds591, 2014 (132).

R. Sankar, P. Singh, Synthesis of 7075 Al/SiC particulate composite powders by mechanical alloying. Materials Letters36, 1998 (201).

Y. Tian, Y. Shen, C. Lu, X. Feng, Microstructures and oxidation behavior of Al-CrMnFeCoMoW composite coatings on Ti–6Al–4 V alloy substrate via high-energy mechanical alloying method. Journal of Alloys and Compounds779, 2019 (456).

C. Yan, D. Xiong, J. Li, Synthesis of Ni–Al–Ta composite coatings on Al alloy plates and the transfer of Al powder via mechanical milling technique. Powder Technology340, 2018 (234).

V.Y. Zadorozhnyy, A. Shahzad, M.D. Pavlov, D.S. Kozak, A.M. Chirkov, D.S. Zagrebin, R.S. Khasenova, S.V. Komarov, S.D. Kaloshkin, Synthesis of the Ni-Al coatings on different metallic substrates by mechanical alloying and subsequent laser treatment. Journal of Alloys and Compounds707, 2017 (351).

S. Romankov, Y.C. Park, S.V. Komarov, Formation of composite CuWNi layers on ceramic substrates under shot impact treatment. Journal of Alloys and Compounds689, 2016 (777).

M. Bulanova, L. Tretyachenko, M. Golovkova, K. Meleshevich, Phase equilibria in the α-Ti-Al-Si region of the Ti–Si–Al system. Journal of Phase Euilibria and Diffusion25, 2004 (209).

I. Barin, Thermochemical data of pure substances, 3rd ed, (Wiley-VCH Verlag GmbH, Weinheim, 1995).

C. Chen, X. Feng, Y. Shen, Effects of annealing treatment and pre-refinement of raw material on microstructures and properties of mechanically alloyed Cr–Al composite coatings on Ti–6Al–4 V alloy. Materials Characterization120, 2016 (97).

J. Li, P. Eveno, A.M. Huntz, Oxidation of SiC. Materials and Corrosion-Werkstoffe und Korrosion41, 1990 (716).

S. Krishnan, J.R.K. Weber, S. Ansell, A.D. Hixson, P.C. Nordine, Structure of Liquid Al6Si2O13 (3:2 Mullite). Journals of the American Ceramic Society83, 2000 (2777).

Acknowledgement

This work was supported by the Natural Science Foundation of the Jiangsu Higher Education Institutions of China (Grant No. 18KJB460017), the Introduce Talent Special Funding for Scientific Research at Nanjing Tech University (Grant No. 39802125) and the National Natural Science Foundation of China (Grant No. 51475232).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, C., Feng, X. & Shen, Y. Effect of Annealing Treatment on Microstructure, Mechanical Properties and Oxidation Resistance of SiCp/Al Coating Synthesized on Ti–6Al–4 V Alloy Substrate by Mechanical Alloying Method. Oxid Met 94, 127–146 (2020). https://doi.org/10.1007/s11085-020-09982-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-020-09982-7