Abstract

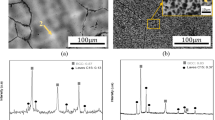

The choice of materials is of great concern in the construction of Gen IV supercritical water-cooled reactors (SCWRs), particularly the fuel cladding, due to the harsh environment of elevated temperatures and pressures. Material’s performance under simulated conditions must be evaluated to support proper material selection by designers. In this study, alloys 800H, 3003 and 304 were tested in SCW at 700 °C and 25 MPa for 1000 h. The results showed that only alloy 3033 experienced weight gain while weight loss was found for alloys 304 and 800H. Based on SEM/EDS and XRD analyses, spinel and Cr2O3, in addition to small amount of Fe2O3, formed on 800H surface, while predominant Cr2O3 and some spinel were present on alloy 3033. Alloy 304 showed no evidence of Cr2O3 on the surface, although some Cr-containing spinel and Fe2O3 were detected on the surface.

Similar content being viewed by others

References

World population to 2300, United Nations Department of Economic and Social, New York, 2004.

Nuclear Energy Research Advisory Committee and Gen IV International Forum, DOE, US, 2002.

T. Schulenberg, H. Matsui, L. Leung and A. Sedov, Supercritical water cooled reactors, in GIF Symposium Proceedings and 2012 Annual Report, San Diego, 2012.

M. Yetisir, M. Gaudet and D. Rhodes, Development and integration of Canadian SCWR concept with counter-flow fuel assembly, in ISSCWR-6, Shenzhen, 2013.

R. Klueh, Elevated temperature ferritic and martensitic steels and their application to future nuclear reactors, Int Mat Rev 50, 287–310 (2005).

S. Briefing, Nickel-based super alloys, in INSG Insight, 2003.

L. Zhang, F. Zhu, Y. Bao and R. Tang, Corrosion tests of candidate fuel cladding and reactor internal structural materials, in 2nd Canada-China joint workshop on ‘Supercritical water-cooled reactors’, Toronto, 2010.

T. Allen, Y. Chen, X. Ren, K. Sridhara, L. Tan, G. Was, E. West, and D. Guzonas, in Material Performances in Supercritical Water. Comprehensive Nuclear Materials, (Elsevier, Amsterdam, 2012), pp. 279–326.

L. Greenwood, A new calculation of thermal neutron damage and helium production in nickel. J Nucl Mat 115, 137–142 (1983).

G. Was, P. Ampornrat, G. Gupta, S. Teysseyre, E. West, T. Allen, K. Sridharan, L. Tan, Y. Chen, X. Ren and C. Pister, Corrosion and stress corrosion cracking in supercritical water. J Nucl Mater 371, 176–201 (2007).

K. Ehrlich, J. Konys and L. Heikinheimo, Materials for high performance light water reactor. J Nucl Mater 327, 140–147 (2004).

K. Murty and I. Charit, Structural materials for Gen-IV nuclear reactor: challlenges and opportunities. J Nucl Mater 383, 189–195 (2008).

Y. Nakazono, T. Iwai and H. Abe, General corrosion properties of modified PNC1520 austenitic stainless steel in supercritical water as fuel cladding candidate material for supercritical water reactor. J Phy Conf Ser 215, 012094 (2010).

R. Peraldi and B. Pint, Effect of Ni and Cr contents on the oxidation behaviour of ferritic and austenitic model alloys in air with water vapor. Oxidation of Metals 61, 463–483 (2004).

W. Callister, Materials science and engineering an introduction, (John Wiley & Sons Inc., New York, 2007).

A. Fry, S. Osgerby and M. Wright, Oxidation of alloys in steam envrironments- a review. National Physical Laboratory Report MATC 90, 1–39 (2002).

Y. Otoguro, M. Sakakibara, T. Saito, H. Ito and Y. Inoue, Oxidation behaviour of austenitic heat-resisting steels in a high temperature and high pressure steam environment. Trans Iron Steel Inst Japan 28, 761–768 (1988).

S. Bsat and X. Huang, Corrosion behaviour of alloy 800H in low density superheated steam. ISIJ Int 56, 1067–1075 (2016).

Sand Meyer Steel Company, Specification sheet: Alloy 800H/800HT, [Online]. Available: http://www.sandmeyersteel.com/images/Alloy800H-800HT-APR2013.pdf. [Accessed May 2016].

Nickel Development Institute, High temperature characteristics of stainless steels, [Online]. Available: http://www.nickelinstitute.org/~/Media/Files/TechnicalLiterature/High_TemperatureCharacteristicsofStainlessSteel_9004_.pdf. [Accessed May 2016].

VDM Metals, VDM Alloy 33 Nicrofer 33, [Online]. Available: http://www.vdm-metals.com/fileadmin/user_upload/Downloads/Data_Sheets/Data_Sheet_VDM_Alloy_33.pdf. [Accessed May 2016].

S. Saunders, The oxidation behaviour of metals and alloys at high temperatures in atmospheres containing water vapour: A review. Prog Mat Sci 53, 775–837 (2008).

T. Allen, K. Sridharan, Y. Chen, L. Tan, X. Ren and A. Kruizenga, Research and Development on Materials Corrosion Issues in Supercritical Water Environment, in ICPWS XV, Berlin, 2008.

L. Tan, R. X, K. Sridharan and T. Allen, Corrosion behaviour of Ni-base alloys for advanced high temperature water-cooled nuclear reactions, Corr Sci, vol. 50, pp. 3056–3062, 2008.

S. Penttila, Private communication.

J. Rezek, I. Klein and J. Yahalom, Structure and Corrosion Resistance of Oxide Grown on Maraging Steel in Steam at Elevated Temperatures. App Surf Sci 108, 159–165 (1997).

T. Allen, Y. Chen, L. Tan, X. Ren and K. Sridharan, Corrosion of Candidate Materials for Supercritical Water-Cooled Reactors, in 12th International Conference on Environmental Degradation of Materials in Nuclear Power System – Water Reactors, Warrendale, 2005.

M. Fulger, D. Ohai, M. Mihalache, M. Pantiru and V. Malinovchi, Oxidation Behaviour of Incoloy 800 Under Simulated Supercritical Water Conditions. J Nucl Mat 385, 288–293 (2009).

B. A. Pint, K. A. Terrani, M. P. Brady, T. Cheng and J. R. Keiser, High temperature oxidation of fuel cladding candidate materials in steam–hydrogen environments. Journal of nuclear materials 440, (1), 420–427 (2013).

S. Mahboubi, G. Botton and J. Kish, Technical Note: Corrosion Resistance of Alloy 33 (Fe-33Cr-32Ni) in Supercritical Water. Corrosion 71, 1064–1070 (2015).

X. Luo, R. Tang, C. Long, Z. Miao, Q. Peng and C. Li, Corrosion behavior of austenitic and ferritic steels in supercritical water. Nucl Eng Tech 40, 147–154 (2007).

G. Was, S. Teysseyre and Z. Jiao, Corrosion of Austenitic Alloys in Supercritical Water. Corrosion 62, 989–1005 (2006).

D. Rodriguez, A. Merwin and D. Chidambaram, On the oxidation of stainless steel alloy 304 in subcritical and supercritical water. J Nucl Mat 452, 440–445 (2014).

S. F. Li and et al., Corrosion Behaviour of a 304-Oxide Dispersion Strengthened Austenitic Stainless Steel in Supercritical Water, Materials and Corrosion, vol. 67, no. 3, pp. 264–270, 2016.

G. H. Meier, A Review of Advances in High Tmeperature Corrosion. Materials Science and Engineering A120–121, 1–11 (1989).

R. M. Deacon, Investigation of Corrosion Resistance of Candidate Overlay Alloys in High Temperature Low Nox Environment, (Lehigh University, Thesis, 2004).

X. Huang, J. Li and D. Guzonas, Characterization of FeCrAlY Alloy in Supercritical Water. Corrosion Engineering Science and Technology 50, (2), 137–148 (2015).

Acknowledgements

Funding to the Canada Gen IV National Program was provided by Natural Resources Canada through the Office of Energy Research and Development, Atomic Energy of Canada Limited and Natural Sciences and Engineering Research Council of Canada.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bsat, S., Xiao, B., Huang, X. et al. Oxidation Behaviour of Alloys 800H, 3033 and 304 in High-Temperature Supercritical Water. Oxid Met 89, 151–163 (2018). https://doi.org/10.1007/s11085-017-9784-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-017-9784-7