Abstract

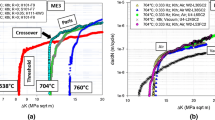

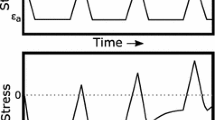

The present paper summarizes experimental work to identify the mechanisms of dwell-time cracking during service operation of polycrystalline nickel-base superalloys, such as Alloy 718 and AD730. By means of crack growth monitoring during various kinds of cyclic loading in vacuum and in air using the potential drop technique, it was shown that the combination of sustained tensile stress, load reversal, and oxidizing atmosphere leads to an increase in the crack propagation rate by orders of magnitude, as compared to cyclic reference tests without dwell time and/or under vacuum conditions. By careful metallographic and theoretical analysis, the embrittling effect was attributed to stress-induced oxygen diffusion ahead of the intergranular crack tip followed by decohesion in a nanometer scale and had been termed “dynamic embrittlement.” More recently, atom probe tomography of the near-crack tip region revealed that the damage zone consists of Cr-rich transition oxides rather than elemental oxygen. This is in qualitative agreement with TGA measurements on Alloy 718 specimens without mechanical loading, which shows that crack propagation velocities of 50 µm/s do not allow massive Cr2O3 or NiO scale formation. By means of a quantitative analysis of the fracture surface, it became evident that grain-boundary attack depends on the grain-boundary character. This observation was supported by four-point bending experiments on grain-boundary-engineered samples with a high fraction of coincident site lattice boundaries and bicrystalline samples with well-defined grain-boundary misorientation relationships with respect to the loading axis. Taking the experimental results into account, semiquantitative modeling concepts have been developed to correlate crack propagation rates with the oxygen grain-boundary diffusivity, the local microstructure, and the mechanical stress states. These concepts are discussed in terms to adapt grain size and precipitate microstructure of polycrystalline superalloys.

Similar content being viewed by others

References

U. Krupp, International Materials Reviews 50, 83 (2005).

A. Pineau and S. D. Antolovich, Engineering Failure Analysis, Vol. 16, p. 2668, (2009).

J. A. Pfaendtner and C. J. McMahon Jr., Acta Materialia 49, 3369 (2001).

M. F. Browning and M. F. Henry, in E. A. Loria (ed.), Proceedings of Superalloys 718, 625 and Various Derivates (TMS, 1997), p. 665.

K. Löhnert, Doctorate Thesis, Friedrich Alexander University Erlangen-Nürnberg 2011.

W. J. Ostergreen, Journal of Testing and Evaluation 4, 327 (1976).

E. Lundström, K. Simonsson, D. Gustafsson and T. Månsson, Engineering Fracture Mechanics 118, 17 (2014).

K. Wackermann, Doctorate Thesis, University of Siegen 2014.

U. Krupp, Journal of Materials Science 43, 3908 (2008).

W. Kane, PhD Thesis, University of Pennsylvania, Philadelphia 2005.

M. Hörnqvist, L. Viskari, K. L. Moore, Y. Cao and K. Stiller, Materials Science and Engineering 609, 131 (2014).

L. Viskari, M. Hörnqvist, K. L. Moore, Y. Cao and K. Stiller, Acta Materialia 61, 3630 (2013).

H. S. Kitaguchi, H. Y. Li, H. E. Evans, R. G. Ding, I. P. Jones, G. Baxter and P. Bowen, Acta Materialia 61, 1968 (2013).

Y. Xu and J. L. Bassani, Materials Science and Engineering, Vol. A260, p. 48 (1999).

Acknowledgements

The financial support by Deutsche Forschungsgemeinschaft (DFG), the Volkswagen Foundation, the Alexander von Humboldt foundation, the Swedish Innovation Agency (VINNOVA), the Swedish High Temperature Corrosion Centre (HTC), and The Swedish Foundation for Strategic Research (SSF) is gratefully acknowledged by the authors. One of the authors (UK) wants to express his deep gratitude to Prof. Charles J. McMahon Jr. for the collaboration and plenty of fruitful discussions not only on dynamic embrittlement.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Krupp, U., Wackermann, K., Christ, HJ. et al. Intergranular Oxidation Effects During Dwell-Time Fatigue of High-Strength Superalloys. Oxid Met 88, 3–14 (2017). https://doi.org/10.1007/s11085-016-9707-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-016-9707-z