Abstract

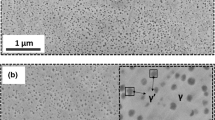

The nickel based alloys IN617 and IN625 that have been selected for their candidacy in the construction of the hottest regions of the supercritical steam cycle have been oxidised under isothermal conditions at 750 °C and atmospheric pressure in atmospheres of 100 % steam, 50/50 % steam/argon and air for up to 4,200 h. Both alloys developed a thin protective oxide under each condition. Scale thickness measurements using SEM micrographs were performed and showed that exposures in steam exhibited a higher rate of scale formation than exposures in air in both alloys. IN617 developed an extensive internal network of alumina which resulted in the formation of alloy protrusions into the scale altering scale growth kinetics, IN625 also formed alumina to a lesser extent. Voids formed in the matrix below the scale in both alloys in each environment. The extent of alumina formation alters the void morphology which eventually impacts the scale growth rate as inward scale growth occurred into the voids in IN625 but not in IN617.

Similar content being viewed by others

References

N. Birks, G. H. Meier, and F. S. Pettit, Introduction to the High-Temperature Oxidation of Metals, 2nd edn. (Cambridge University Press, New York, 2006), p. 76.

D. Young, High Temperature Oxidation and Corrosion of Metals, (Elsevier, London, 2008), p. 455.

I. Wright and R. Dooley, International Materials Reviews 55, 129 (2010).

W. Quadakkers and J. Zurek, Shrier’s Corrosion, 4th edn. (Elsevier, London, 2010), p. 407.

S. Saunders, M. Monteiro, and F. Rizzo, Progress in Materials Science 53, 775 (2008).

INCONEL alloy 617, Technical Bulletin, Special Metals Corporation, SMC-029 (05 March 2005).

INCONEL alloy 625, Technical Bulletin, Special Metals Corporation, SMC-063 (06 Jan 2006).

D. M. Gorman, R. L. Higginson, H. Du, G. McColvin, A. T. Fry, and R. C. Thomson, Materials at High Temperatures 29, 81 (2012).

A. Duval, F. Miserque, M. Tabarant, J.-P. Nogier, and A. Gédéon, Oxidation of Metals 74, 215 (2010).

E. Essuman, L. R. Walker, P. J. Maziasz, and B. A. Pint, 8th International Charles Parsons Turbine Conference (2011).

D. Kim, C. Jang, and W. S. Ryu, Oxidation of Metals 71, 271 (2009).

C. Jang, D. Lee, and D. Kim, International Journal of Pressure Vessels and Piping 85, 368 (2008).

V. Shankar, K. B. S. Rao, and S. L. Mannan, Journal of Nuclear Materials 288, 222 (2001).

R. Peraldi, D. Monceau, and B. Pieraggi, Oxidation of Metals 58, 249 (2001).

A. Paul, M. J. H. van Dal, A. A. Kodentsov, and F. J. J. van Loo, Acta Materialia 52, 623 (2004).

S. Guruswamy, S. M. Park, J. P. Hirth, and R. A. Rapp, Oxidation of Metals 26, 77 (1986).

S. W. Guan, H. C. Yi, and W. W. Smeltzer, Oxidation of Metals 41, 377 (1994).

F. H. Stott and G. C. Wood, Science and Technology 4, 1072 (1988).

P. Huczkowski, N. Christiansen, V. Shemet, J. Piron-Abellan, L. Singheiser, and W. J. Quadakkers, Science and Technology 1, 31 (2004).

Acknowledgments

We would like to acknowledge financial support from both EPSRC (Grant No. EP/G037345/1) through the Doctoral Training Centre in Efficient Fossil Energy Technologies and Alstom Power Ltd. We would also like to express our gratitude to the National Physical Laboratory for supplying the steam exposed materials with the support of the UK Department for Business, Innovation and Skills.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gorman, D.M., Higginson, R.L., Du, H. et al. Microstructural Analysis of IN617 and IN625 Oxidised in the Presence of Steam for use in Ultra-Supercritical Power Plant. Oxid Met 79, 553–566 (2013). https://doi.org/10.1007/s11085-012-9342-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-012-9342-2