Abstract

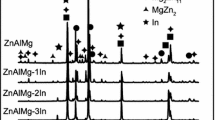

The oxidation properties of Sn–8.5Zn–0.5Ag–0.1Al–xGa lead-free solders in the liquid state (250 °C) under O2 atmosphere were investigated using a thermal gravimetric analyzer. The Ga content of the investigated solders was 0.05–2 wt%. The results indicate that Ga enhances the oxidation resistance of Sn–Zn–Ag–Al solder. Cross-sections of the solder surfaces were examined using focus ion beam milling. The thickness of the oxidation layer, which was about 30–100 nm, increased with increasing Ga content. The oxidation layer was found to be nonuniform at low Ga content. The oxide layers on the surface of solders were investigated using Auger electron spectroscopy and thin-film XRD. The results showed that the oxide layer formed was ZnO. Al and Ga tended to segregate on the surface of the solder.

Similar content being viewed by others

References

W. Yang and R. W. Messler Jr., Journal of Electronic Materials 23, 765 (1994).

H. Mavoori, J. Chin, S. Vaynman, B. Moran, L. Keer, and M. E. Fine, Journal of Electronic Materials 41, 1269 (1997).

M. McCormack, S. Jin, and G. W. Kammlott, Proceedings of the 1995 IEEE International Symposium on Electronics and the Enviornment, ISEE, May 1–3 1995, Orlando, FL, USA (1995), p. 171.

F. G. Yost, F. M. Hosking, and D. R. Frear, The Mechanics of Solder Alloy, Wetting & Spreading, (Van Nostrand Reinhold, New York, 1993), p. 155.

D. M. Tench, D. P. Anderson, and P. Kim, Journal of Applied Electrochemistry 24, 18 (1994).

S. Vaynman and M. E. Fine, Journal of Electronic Materials 29, 1160 (2000).

T. Takemoto and T. Funaki, Materials Transactions 43, 1784 (2002).

T. Takemoto, T. Funaki, and A. Matsunawa, Journal of the Japan Welding Society 17, 251 (1999).

C. W. Huang and K. L. Lin, Journal of Materials Research 18, 1528 (2003).

C. W. Huang and K. L. Lin, Materials Transactions 45, 588 (2004).

N. S. Liu and K. L. Lin, Scripta Materialia 54, 219 (2006).

I. Barin, Thermochemical Data of Pure Substances, vol. 2, (VCH, New York, 1995), p. 1549.

K. I. Chen and K. L. Lin, Journal of Electronic Materials 32, 1111 (2003).

R. N. Lyon, Liquid-Metals Handbook, (U.S. Govt. Print. Office, Washington, 1954), p. 40.

Acknowledgments

The financial support of this work by the National Science Council of the Republic of China under grant NSC-93-2216-E006-011 is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, NS., Lin, KL. Effect of Ga on the Oxidation Properties of Sn–8.5Zn–0.5Ag–0.1Al–xGa Solders. Oxid Met 78, 285–294 (2012). https://doi.org/10.1007/s11085-012-9306-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-012-9306-6