Abstract

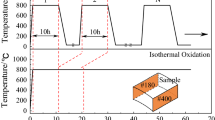

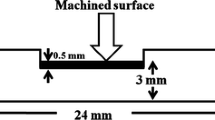

The influence of surface preparation on the stress and adhesion of oxide scales formed on the ferritic stainless steel AISI 441 was studied. Steel coupons were surface-finished to different degrees of surface roughness from 400-grit SiC through to 1-micron diamond, and were also electropolished to remove the work hardened surface. Initial metal roughness was measured by optical profilometry. Oxidation was carried out at 800 °C under synthetic air for 100 h. Oxide residual stress was derived from the Raman shift of the main chromia line, and adhesion of oxide scales was quantitatively obtained using forced spallation by tensile straining. The results show that surface hardening is the most influential factor on adhesion, with the high dislocation-containing mirror-polished samples exhibiting the lowest adhesion energy (~4 J m−2), and the electropolished samples with non-mechanically affected surface exhibiting the highest adhesion energy (17 J m−2). Recrystallisation of the subsurface zone during heating to the oxidation temperature is thought to be the most influential factor reducing scale adhesion.

Similar content being viewed by others

References

M. Dokiya, Solid State Ionics 152–153, 383 (2002).

Z. Yang, K. S. Weil, D. M. Paxton, and J. W. Stevenson, Journal of the Electrochemical Society 150, 1188 (2003).

W. J. Quadakkers, J. Piron-Abellan, V. Shemet, and L. Singheiser, Materials at High Temperatures 20, 115 (2003).

K. Hilpert, D. Das, M. Miller, D. H. Peck, and R. Weib, Journal of the Electrochemical Society 143, 3642 (1996).

Y. Matsuzaki and I. Yasuda, Journal of the Electrochemical Society 148, 126 (2001).

P. Y. Hou and J. L. Smialek, Scripta Metallurgia 33, 1409 (1995).

P. Y. Hou, Materials Science Forum 369–372, 23 (2001).

P. Y. Hou and K. Priimak, Oxidation of Metals 63, 113 (2005).

I. Belogolovsky, P. Y. Hou, C. P. Jacobson, and S. J. Visco, Journal of Power Sources 182, 259 (2008).

J. Mougin, M. Dupeux, L. Antoni, and A. Galerie, Materials Science and Technology 9, 544 (2003).

S. Chandra-Ambhorn, F. Roussel-Dherbey, F. Toscan, Y. Wouters, A. Galerie, and M. Dupeux, Materials Science and Technology 23, 497 (2007).

S. Chandra-Ambhorn, Y. Wouters, L. Antoni, F. Toscan, and A. Galerie, Journal of Power Sources 171, 688 (2007).

P. Y. Hou and S. R. J. Saunders, Materials at High Temperatures 22, 119 (2005).

J. Mougin, M. Dupeux, L. Antoni, and A. Galerie, Materials Science and Engineering A359, 44 (2003).

A. Galerie, M. Dupeux, Y. Wouters, and F. Toscan, Materials Science Forum 522–523, 441 (2006).

I. R. Sohn and T. Narita, Oxidation of Metals 59, 333 (2003).

M. S. Li and P. Y. Hou, Acta Materialia 55, 443 (2007).

G. Bamba, Y. Wouters, A. Galerie, G. Borchardt, S. Shimada, O. Heintz, and S. Chevalier, Scripta Materialia 57, 671 (2007).

D. Caplan, M. J. Graham, and M. Cohen, Journal of the Electrochemical Society 119, 1205 (1973).

J. Mougin, G. Lucazeau, A. Galerie, and M. Dupeux, Materials Science and Engineering A308, 118 (2001).

S. Mohan, D. Kanagaraj, R. Sindhuja, S. Vijayalakshmi, and N. G. Renganathan, Transaction of the IMF 79, 140 (2001).

H. Zhao, J. Van Humbeeck, J. Sohier, and I. De Scheerder, Journal of Materials Science: Materials in Medicine 13, 911 (2002).

W. C. Oliver and G. M. Pharr, Journal of Materials Research 19, 3 (2004).

J. Birnie, C. Craggs, D. J. Gardiner, and P. R. Graves, Corrosion Science 33, 1 (1992).

J. Mougin, T. Le Bihan, and G. Lucazeau, Journal of the Physical Chemistry of Solids 62, 553 (2001).

A. Galerie, J. Mougin, M. Dupeux, N. Rosman, and G. Lucazeau, in John Stringer Symposium on High Temperature Corrosion eds. P.F. Tortorelli, I.G. Wright, and P.H. Hou, (2001).

A. Galerie, F. Toscan, E. N’Dah, K. Przybylski, Y. Wouters, and M. Dupeux, Materials Science Forum 461–464, 631 (2004).

S. Chandra-ambhorn, F. Roussel-Dherbey, F. Toscan, Y. Wouters, A. Galerie and M. Dupeux, Materials Science and Technology 23, 497 (2007).

F. Toscan, L. Antoni, M. Dupeux and A. Galerie, Materials at High Temperatures 20, 297 (2003).

C. S. Giggins and F. S. Pettit, Transactions of the Metallurgical Society of AIME 245, 2509 (1969).

F. Toscan, L. Antoni, Y. Wouters, M. Dupeux, and A. Galerie, Materials Science Forum 461–464, 2004 (705).

J. M. Rakowski, et al., Scripta Materialia 35, 1417 (1996).

Acknowledgments

This work is part of the PhD thesis of Y. Madi, who thanks the Algerian government for supporting an 18-month stay in Grenoble. The authors are indebted to Dr. Francis Baillet for roughness measurements, and to Dr. Marc Verdier for nanoindentation testing.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Madi, Y., Salhi, E., Charlot, F. et al. Influence of Polishing-Induced Surface Hardening on the Adhesion of Oxide Scales Grown on a Ferritic Stainless Steel. Oxid Met 75, 167–181 (2011). https://doi.org/10.1007/s11085-010-9226-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-010-9226-2