Abstract

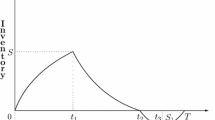

A two storage production-repairing system for a single item with stock-dependent demand is considered. Item is produced with fuzzy defective rate at a production center with a warehouse. Units are bulkly transformed from production center (PC) to a showroom (SR) at the market for sale and excess units are stored at the production center warehouse. After the production period, repairing process is commissioned and then defective units are repaired to new condition before being sold again. Model is formulated as a profit maximization problem using fuzzy differential equation and three different approaches—α-cut of fuzzy average profit, expected value and necessity measure of fuzzy event for defuzzification. A genetic algorithm (GA) with binary mode representation, Roulette wheel selection and random mutation process is used to solve the model. In the first approach, using fuzzy preference ordering of intervals (FPOI), α-cut of fuzzy average profit is optimized using the above GA to derive optimum decisions for the decision maker (DM). In second approach, expected value of average profit is obtained and is optimized using the above GA for optimal decision. In another approach fuzzy objective is directly optimized using necessity measure of fuzzy events for finding marketing decisions. The proposed model is illustrated with numerical examples and results obtained using different approaches are compared.

Similar content being viewed by others

References

Allahviranloo T, Shafiee M, Nejatbakhsh Y (2009) A note on “Fuzzy differential equations and the extension principle, Information Sciences”. Inf Sci 179:2049–2051

Buckley JJ, Feuring T (2000) Fuzzy differential equations. Fuzzy Sets Syst 110:43–54

Chalco-Cano Y, Roman-Flores H (2009) Comparation between some approaches to solve fuzzy differential equations. Fuzzy Sets Syst 160:1517–1527

Dobos I, Richter K (2000) The integer EOQ repair and waste disposal model further analysis. Cent Eur J Oper Res 8:173–194

Dubois D, Prade H (1983) Ranking fuzzy numbers in the setting of possibility theory. Inf Sci 30:183–224

Dubois D, Prade H (1988) Possibility theory: an approach to computerized processing of uncertainty. Plenum, New York

Giri BC, Pal C, Goswami A, Chaudhuri KS (1996) An inventory model for deteriorating items with stock dependent demand rate. Eur J Oper Res 95:604–610

Goyal SK, Cardenas-Barron LE (2002) Note on economic production quantity model for items with imperfect quality a practical approach. Int J Prod Econ 77:85–87

Holland HJ (1975) In: Adaptation in natural and artificial systems. University of Michigan, Ann Arbor

Khouja M (1995) The economic production lot size model under volume flexibility. Comput Oper Res 22:515–525

Koh SG, Hwang H, Sohn KI, Ko CS (2002) An optimal ordering and recovery policy for reuseable items. Comput Ind Eng 43:59–73

Konstantaras I, Papachristos S (2008) A note on: developing an exact solution for an inventory system with product recovery. Int J Prod Econ 111:707–712

Levin RI, Mclaughlin CP, Lamone RP, Kothas JF (1972) Production/operations management: contemporary policy for managing operating systems. McGraw-Hill, New York

Liu B, Iwamura K (1998) Chance constraint programming with fuzzy parameters. Fuzzy Sets Syst 94:227–237

Liu B, Liu YK (2002) Expected value of fuzzy variable and fuzzy expected value models. IEEE Trans Fuzzy Syst 10:445–450

Liu Y, Liu B (2003) A class of fuzzy random optimization: expected value models. Inf Sci 155:89–102

Mabini MC, Gelders LF (1991) Repairable item inventory systems: a literature review. Belg J Oper Res Stat Comput Sci 30(4):58–69

Maity AK (2011) One machine multiple-product problem with production-inventory system under fuzzy inequality constraint. Appl Soft Comput 11:1549–1555

Maiti MK (2008) Fuzzy inventory model with two warehouses under possibility measure on fuzzy goal. Eur J Oper Res 188:746–774

Maiti MK, Maiti M (2005) Production policy for damageable items with variable cost function in an imperfect production process via genetic algorithm. Math Comput Model 42:977–990

Maiti MK, Maiti M (2006) Fuzzy inventory model with two warehouses under possibility constraints. Fuzzy Sets Syst 157:52–73

Mandal M, Maiti M (2000) Inventory of damageable items with variable replenishment and stock-dependent demand. Asia-Pac J Oper Res 17:41–54

Mandal BN, Phaujdar S (1989) An inventory model for deteriorating items and stock dependent consumption rate. J Oper Res Soc 40:483–488

Mandal S, Maity AK, Maity K, Mondal S, Maiti M (2011) Multi-item multi-period optimal production problem with variable preparation time in fuzzy stochastic environment. Appl Math Model 35(9):4341–4353

Michalewicz Z (1992) Genetic algorithms + data structures = evolution programs. Springer, Berlin

Mizukoshi MT, Barros LC, Chalco-Cano Y, Roman-Flores H, Bassanezi RC (2007) Fuzzy differential equations and the extension principle. Inf Sci 177:3627–3635

Omar M, Yeo I (2009) A model for a production-repair system under a time-varying demand process. Int J Prod Econ 119:17–23

Porteus EL (1986) Optimal lot sizing, process quality improvement and setup cost reduction. Oper Res 34:137–144

Richter K (1997) Pure and mixed strategies for the EOQ repair and waste disposal problem. OR Spektrum 19:123–129

Roy A, Maity K, Kar S, Maiti M (2009) A production inventory model with remanufacturing for defective and usable items in fuzzy-environment. Comput Ind Eng 56:87–96

Salameh MK, Jaber MY (2000) Economic production quantity model for items with imperfect quality. Int J Prod Econ 64:59–64

Sengupta A, Pal T (2009) Fuzzy preference ordering of interval numbers in decision problems. Springer, Berlin

Teunter RH (2004) Lot-sizing for inventory systems with product recovery. Comput Ind Eng 46(3):431–441

Urban TL (1995) Inventory models with demand rate dependent on stock and shortage levels. Int J Prod Econ 22:85–93

Wee HM, Yu J, Chen MC (2007) Optimal inventory model for items with imperfect quality and shortage back ordering. Omega 35:7–11

Wu HC (2000) The fuzzy Riemann integral and its numerical integration. Fuzzy Sets Syst 110:1–25

Zadeh LA (1978) Fuzzy sets as a basis for a theory of possibility. Fuzzy Sets Syst 1:3–28

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mondal, M., Maiti, M.K. & Maiti, M. A two storage production-repairing model with fuzzy defective rate and displayed inventory dependent demand. Optim Eng 15, 751–772 (2014). https://doi.org/10.1007/s11081-013-9222-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11081-013-9222-x