Abstract

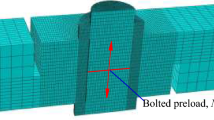

Subjected to dynamic excitations, bolted joint interfaces exhibit nonlinear characteristics that significantly affect the dynamic response of assembled structures. In this paper, a novel modeling method is developed to improve the prediction accuracy of the tangential contact behavior of bolted joint interfaces. This method is based on the framework of the Iwan model and builds the relationship between the Iwan density function and the distribution of the contact pressure. It is the first time to give an explicit physical significance of the Iwan density function. The effectiveness of the proposed model is validated well by comparing with published experiments. Then the proposed model is integrated into a numerical model of a bolted joint structure and combined with the alternating frequency/time method to study its applicability in dynamics analysis. The model is fully compatible with the current state-of-the-art numerical analysis tools. The results show that the simulated interface responses are in good agreement with the experiment.

Similar content being viewed by others

References

De Benedetti, M., Garofalo, G., Zumpano, M., et al.: On the damping effect due to bolted junctions in space structures subjected to pyro-shock. Acta Astronaut. 60, 947–956 (2007)

Tang, Q., Li, C., She, H., et al.: Modeling and dynamic analysis of bolted joined cylindrical shell. Nonlinear Dyn. 93, 1953–1975 (2018)

Brake, M.R.W., et al.: The Mechanics of Jointed Structures: Recent Research and Open Challenges for Developing Predictive Models for Structural Dynamics. Springer, Berlin (2017)

Gaul, L., Lenz, J.: Nonlinear dynamics of structures assembled by bolted joints. Acta Mech. 125, 169–181 (1997)

Gaul, L., Nitsche, R.: The role of friction in mechanical joints. Appl. Mech. Rev. 54, 93–106 (2001)

Oldfield, M., Ouyang, H., Mottershead, J.E.: Simplified models of bolted joints under harmonic loading. Comput. Struct. 84, 25–33 (2005)

Ames, N.M., Lauffer, J.P., Jew, M.D., et al.: Handbook on dynamics of jointed structures, No. SAND2009-4164. Sandia National Laboratories (2009)

Ouyang, H., Oldfield, M.J., Mottershead, J.E.: Experimental and theoretical studies of a bolted joint excited by a torsional dynamic load. Int. J. Mech. Sci. 48, 1447–1455 (2006)

Kim, J., Yoon, J.C., Kang, B.S.: Finite element analysis and modeling of structure with bolted joints. Appl. Math. Model. 31, 895–911 (2007)

Reid, J.D., Hiser, N.R.: Detailed modeling of bolted joints with slippage. Finite Elem. Anal. Des. 41, 547–562 (2005)

Schwingshackl, C.W., Di Maio, D., Sever, I., et al.: Modeling and validation of the nonlinear dynamic behavior of bolted flange joints. J. Eng. Gas Turb. Power 135, 122504 (2013)

Wu, Y.G., Li, L., Fan, Y., et al.: Design of dry friction and piezoelectric hybrid ring dampers for integrally bladed disks based on complex nonlinear modes. Comput. Struct. 233, 106237 (2020)

Firrone, C.M., Zucca, S., Gola, M.M.: The effect of underplatform dampers on the forced response of bladed disks by a coupled static/dynamic harmonic balance method. Int. J. Non-Linear Mech. 46, 363–375 (2011)

Cigeroglu, E., An, N., Menq, C.H.: A microslip friction model with normal load variation induced by normal motion. Nonlinear Dyn. 50, 609 (2007)

Armand, J., Salles, L., Schwingshackl, C.W., et al.: On the effects of roughness on the nonlinear dynamics of a bolted joint: a multiscale analysis. Eur. J. Mech. A Solid 70, 44–57 (2018)

Segalman, D.J.: A four-parameter Iwan model for lap-type joints. J. Appl. Mech. 72, 752–760 (2005)

Segalman, D.J.: Modelling joint friction in structural dynamics. Struct. Control Health 13, 430–453 (2006)

Miller, J.D., Quinn, D.D.: A two-sided interface model for dissipation in structural systems with frictional joints. J. Sound Vib. 321, 201–219 (2009)

Song, Y., Hartwigsen, C.J., McFarland, D.M., et al.: Simulation of dynamics of beam structures with bolted joints using adjusted Iwan beam elements. J. Sound Vib. 273, 249–276 (2004)

Armand, J., Pesaresi, L., Salles, L., et al.: A modelling approach for the nonlinear dynamics of assembled structures undergoing fretting wear. Proc. R. Soc. A Math. Phys. 475, 20180731 (2019)

Iwan, W.D.: On a class of models for the yielding behavior of continuous and composite systems. J. Appl. Mech. 34, 612–617 (1967)

Iwan, W.D.: A distributed-element model for hysteresis and its steady-state dynamic response. J. Appl. Mech. 33, 893–900 (1966)

Valanis, K.C.: A theory of viscoplasticity without a yield surface. Arch. Mech. Stos. 23, 515–553 (1971)

Gaul, L., Lenz, J., Sachau, D.: Active damping of space structures by contact pressure control in joints. J. Struct. Mech. 26, 81–100 (1998). https://doi.org/10.1080/08905459808945421

De Wit, C.C., Olsson, H., Astrom, K.J., et al.: A new model for control of systems with friction. IEEE Trans. Autom. Control 40, 419–425 (1995)

Dahl, P.R.: Solid friction damping of mechanical vibrations. AIAA J. 14(12), 1675–1682 (1976)

Jenkins, G.M.: Analysis of the stress–strain relationships in reactor grade graphite. Br. J. Appl. Phys. 13, 30–32 (1962)

Li, Y., Hao, Z.: A six-parameter Iwan model and its application. Mech. Syst. Signal Process. 68, 354–365 (2016)

Brake, M.R.W.: A reduced Iwan model that includes pinning for bolted joint mechanics. Nonlinear Dyn. 87(2), 1335–1349 (2017)

Biswas, S., Chatterjee, A.: A two-state hysteresis model for bolted joints, with minor loops from partial unloading. Int. J. Mech. Sci. 140, 506–520 (2018)

Wang, D., Xu, C., Fan, X., Wan, Q.: Reduced-order modeling approach for frictional stick-slip behaviors of joint interface. Mech. Syst. Signal Process. 103, 131–138 (2018)

Li, D., Xu, C., Liu, T., Gola, M.M., Wen, L.: A modified IWAN model for microslip in the context of dampers for turbine blade dynamics. Mech. Syst. Signal Process. 121, 14–30 (2019)

Li, D., Botto, D., Xu, C., et al.: A micro-slip friction modeling approach and its application in underplatform damper kinematics. Int. J. Mech. Sci. 161, 105029 (2019)

Marshall, M.B., Lewis, R., Dwyer-Joyce, R.S.: Characterization of contact pressure distribution in bolted joints. Strain 42, 31–43 (2006)

Mantelli, M., Milanez, F.H., Pereira, E., et al.: Statistical model for pressure distribution of bolted joints. J. Thermophys. Heat Transf. 24, 432–437 (2010)

Segalman, D.J., Starr, M.J.: Inversion of Masing models via continuous Iwan systems. Int. J. Non-Linear Mech. 43, 74–80 (2008)

Eriten, M., Polycarpou, A.A., Bergman, L.A.: Development of a lap joint fretting apparatus. Exp. Mech. 51(8), 1405–1419 (2011)

Eriten, M.: Multiscale physics-based modeling of friction. Doctoral dissertation, University of Illinois at Urbana-Champaign. (2012)

Cameron, T.M., Griffin, J.H.: An alternating frequency/time domain method for calculating the steady-state response of nonlinear dynamic systems. J. Appl. Mech. 56, 149–154 (1989)

Süß, D.: Multi-harmonische-balance-methoden zur untersuchung des übertragungsverhaltens von strukturen mit fügestellen. Ph.D. thesis, Dissertation. Friedrich-Alexander-Universität Erlangen-Nürnberg (FAU), Erlangen, (2016)

Sanliturk, K.Y., Ewins, D.J.: Modelling two-dimensional friction contact and its application using harmonic balance method. J. Sound Vib. 193, 511–523 (1996)

Wu, Y.G., Li, L., Fan, Y., et al.: Design of semi-active dry friction dampers for steady-state vibration: sensitivity analysis and experimental studies. J. Sound Vib. 459, 114850 (2019)

Acknowledgements

The authors would like to acknowledge the financial support by China Science Challenge Project (TZ2018007). Dongwu Li acknowledges the support provided by the China Scholarship Council (CSC) during a visit to the AERMEC lab of Politecnico di Torino.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A: Contact parameters and imposed displacements in the quasi-static tests

See Table 1.

Appendix B: Model parameters of the bolted joint oscillator

See Table 2.

Appendix C: Nonlinear dynamic response simulation

The MHBM is used to approximate dynamic response through Fourier series. Taking the displacement response, as an example, the real solution can be expanded into a series of harmonic components,

where \( \varvec{U}_{\varvec{j}}^{\varvec{c}} \) and \( \varvec{U}_{\varvec{j}}^{\varvec{s}} \) are the sinusoidal and cosinoidal harmonic coefficients, \( \varvec{U}_{\varvec{o}} \) the constant component of displacement individually, \( j \) the order of Fourier series, \( n_{h} \) the truncated order of harmonics and \( \omega \) the principal vibration frequency. Similarly, the vectors of nonlinear force and excitation force can also be approximated in the same way,

The vibration differential equation, Eq. (15), can be transformed to an algebraic form,

where \( Z\left( \omega \right) \) is the dynamic stiffness matrix which represents the linear part of the system and can be defined as,

where the \( \varvec{Z}_{\varvec{j}} \varvec{ }(j = 1, 2, \ldots ,n_{h} ) \) is defined as

Equation (C6) is usually rewritten as a residual form,

where \( \varvec{R} \) is the residual. The residual equation is solved iteratively using a Newton–Raphson method for the steady response amplitude,

where \( \frac{{\partial \varvec{R}}}{{\partial \varvec{u}}} = \varvec{Z}\left(\varvec{\omega}\right) + \frac{{\partial \varvec{f}_{{\varvec{nl}}} }}{{\partial \varvec{u}}} \) is the Jacobian matrix of the system.

Due to the dependent of friction force on relative displacement and velocity of contact interface and its hysteresis characteristics, it is hard to be obtained in frequency domain. Therefore, the AFT method is used to implement the mutual transformation of response signals between time and frequency domains.

After the initial response \( \varvec{u}\left( \varvec{t} \right) \) in time domain is obtained, the friction force \( \varvec{f}_{{\varvec{nl}}} \left( \varvec{t} \right) \) can be calculated using the proposed model. Then the friction force in time domain is transformed into frequency domain using a Fast Fourier Transform. Substituting the friction force, \( \varvec{f}_{{\varvec{nl}}} \left(\varvec{\omega}\right) \), into Eq. (C4) and solving iteratively the algebraic equation to get a new steady solution, \( \varvec{u}(\varvec{\omega})^{{\left( {\varvec{i} + 1} \right)}} \), the updated time domain solution, \( \varvec{u}(\varvec{t})^{{\left( {\varvec{i} + 1} \right)}} \), can be obtained by an inverse Fast Fourier Transform. Subsequently, the friction force is updated according to new response. An iterative process is performed until the solution is convergent. That is, the residual \( \varvec{R} \) is smaller than a given tolerance.

Rights and permissions

About this article

Cite this article

Li, D., Xu, C., Kang, J. et al. Modeling tangential friction based on contact pressure distribution for predicting dynamic responses of bolted joint structures. Nonlinear Dyn 101, 255–269 (2020). https://doi.org/10.1007/s11071-020-05765-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11071-020-05765-6