Abstract

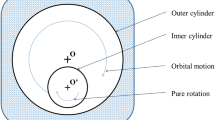

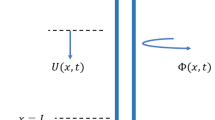

The dynamic characteristics of drilling shaft in deep hole drilling influenced by minimal quantity lubrication (MQL) is investigated. According to the features of the compressible fluid Reynolds equation in oil/air feature, a time-dependent mathematical model is established to describe the pressure distribution of cutting fluid with nonlinearity in MQL deep hole drilling. By introducing the differential transformation approach, the time-dependent pressure equation arising from cutting fluid is solved by the use of direct integral method. The influences of the rotational speed, the transverse displacement ratio, and radial clearance on the hydrodynamic pressure distribution of cutting fluid are obtained. The advantage of this method is to overcome much of the computational cost and has its rapid convergence rate. Furthermore, the nonlinear responses of drilling shaft influenced by MQL are analyzed, and the instability rotational speeds of drilling tool are discussed while the design parameters of drilling shaft system changing.

Similar content being viewed by others

References

Astakhov, V.P., Frazao, J., Osman, M.O.M.: On the experimental optimization of tool geometry for uniform pressure distribution in single edge gundirlling. J. Eng. Ind. 116(4), 449–456 (1994)

Klocke, F., Eisenblätter, G.: Dry cutting-keynote paper. CIRP Ann. Manuf. Tech. 46(2), 519–526 (1997)

Lu, Y.N., Chin, J.H.: Taguchi Method and Neural Network Analyses of Drilling Quality of Deep Hole Drilling Influenced by Minimal Quantity Lubrication and Magneto-Rheological Fluid Vibration Damper. Institute of Mechanical Engineering College of Engineering National Chiao Tung University, Hsinchu (2008)

Wang, L., Takeshi, T.: Research on optimization for key factors required in MQL drilling. Mach. Tool Hydraul. 35(11), 45–47 (2007)

Osman, M.O.M., Chahil, G.S.: A theoretical and experimental investigation of coolant flow and in gundrilling. Int. J. Mach. Tools Manuf. 19(3), 143–155 (1979)

Hu, Z.Q., Zhao, W., Miao, L.: Research on vortex motion of BTA drilling shaft caused by hydro-force. Chin. J. Mech. Eng. 41(1), 230–233 (2005)

Kong, L.F., Li, Y., Lu, Y.J., Li, D.X., Li, S.J., Tang, A.F.: Stability and nonlinear dynamic behavior of drilling shaft system in copper stave deep hole drilling. J. Cent. South Univ. Technol. 16(3), 451–457 (2009)

Kong, L.F., Li, Y., Lü, Y.J., Li, S.J., Tang, A.F.: Nonlinear hydrodynamic force distribution in boring and trepanning association deep hole drilling. Mech. Sci. Tech. Aerosp. Eng. 28(3), 340–345 (2009)

Zhao, H.B., Wang, G.L., Ma, W., et al.: Experimental research on the system performance in near-dry deep hole drilling. Key Eng. Mater. 455, 98–102 (2010)

Chin, J.H., Lee, L.W.: A study on the tool eigen-properties of a BTA deep hole drill—theory and experiments. Int. J. Mach. Tools Manuf. 35(1), 29–49 (1995)

Huang, B.W.: Instability of a cracked twisted beam with a time-dependent boundary. Nonlinear Dyn. 63(4), 627–637 (2011)

Hussien, M.A.W., Rama, B.B., Kudret, D.: Whirling vibration in boring trepanning association deep hole boring process: analytical and experimental investigations. J. Manuf. Sci. Eng. 129(1), 48–62 (2007)

Kong, L.F., Li, Y., Lu, Y.J., Li, D.X.: Complex nonlinear behaviors of drilling shaft system in boring and trepanning association deep hole drilling. Int. J. Adv. Manuf. Technol. 45(3), 211–218 (2009)

Deng, C.S., Chin, J.H.: Roundness errors in BTA drilling and a model of waviness and lobing caused by resonant forced vibrations of its long drill shaft. J. Manuf. Sci. Eng. 126(3), 524–534 (2004)

Deng, C.S., Chin, J.H.: Hole roundness in deep-hole drilling as analyzed by Taguchi methods. Int. J. Adv. Manuf. Technol. 25, 420–426 (2005)

Mehrabadi, I., Nouri, M., Madoliat, M.R.: Investigating chatter vibration in deep drilling, including process damping and the gyroscopic effect. Int. J. Mach. Tools Manuf. 49(12), 939–946 (2009)

Messaoud, A., Weihs, C.: Monitoring a deep hole drilling process by nonlinear time series modeling. J. Sound Vib. 321(3), 620–630 (2009)

Acknowledgements

This work is supported by National Natural Science Foundation of China (Grant No. 51105305), the Major Research Program of Shaanxi Province of China (13115 Project, Grant No. 2009ZDKG-25), Natural Science Foundation of Shaanxi Province of China (Grant No. 2011JQ7012) and Natural Science Foundation of Department of Education of Shaanxi Province of China (Grant No. 2010JK695 and No. 12JK680).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kong, L., Li, Y., Lv, Y. et al. Numerical investigation on dynamic characteristics of drilling shaft in deep hole drilling influenced by minimal quantity lubrication. Nonlinear Dyn 74, 943–955 (2013). https://doi.org/10.1007/s11071-013-1014-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11071-013-1014-5