Abstract

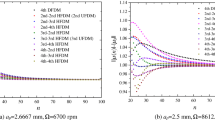

This study presents a Complete Discretization Scheme (CDS) for milling stability prediction. When compared with the Semi-Discretization Method (SDM) and Full-Discretization Method (FDM), the highlight of CDS is that it discretizes all parts of Delay Differential Equation (DDE), including delay term, time domain term, parameter matrices, and most of all the differential term, by using the numerical iteration method, such as Euler’s method, to replace the direct integration scheme used in SDM and FDM, which greatly simplifies the complexity of the discretization iteration formula. The present study mainly provides a numerical framework than a method that can be theoretically used by different numerical methods for solving Ordinary Differential Equation (ODE), such as Euler’s method, Runge–Kutta method, Adam’s multistep methods, etc., in this framework for derivation of iteration formula with corresponding construction of coefficient matrix of iteration formula. This study presented CDS with Euler’s method (CDSEM) for solving the one degree-of-freedom problem (one DOF) and two DOF motion equations, which are usually used as benchmark problems. When compared with SDM and FDM, the benchmark results of one DOF and two DOF milling stability prediction show that CDSEM can obtain acceptable precision in most ranges. The computational efficiency of SDM and FDM was also determined, and the results show that CDS with Euler’s method is faster than FDM. Furthermore, large approximation parameters (small time interval) were selected by SDM and CDSEM, and the results show that CDS has high effectiveness, accuracy, and reliability.

Similar content being viewed by others

References

Tobias, S.A.: Machine Tool Vibration. Blackie, Glazgow (1965)

Konigsberger, F., Tlusty, j.: Machine Tool Structures-Vol.I: Stability Against Chatter. Pergamon, Elmsford (1967)

Pratt, J.R., Nayfeh, A.H.: Design and modeling for chatter control. Nonlinear Dyn. 19(1), 49–69 (1999)

Vela-Martinez, L., Jauregui-Correa, J.C., Gonzalez-Brambila, O.M., Herrera-Ruiz, G., Lozano-Guzman, A.: Instability conditions due to structural nonlinearities in regenerative chatter. Nonlinear Dyn. 56(4), 415–427 (2009)

Banihasan, M., Bakhtiari-Nejad, F.: Chaotic vibrations in high-speed milling. Nonlinear Dyn. 66(4), 557–574 (2011)

Altintas, Y., Budak, E.: Analytical prediction of stability lobes in milling. CIRP Ann. 44(1), 357–362 (1995)

Merdol, S.D., Altintas, Y.: Multi frequency solution of chatter stability for low immersion milling. J. Manuf. Sci. Eng. 126(3), 459–466 (2004)

Bayly, P.V., Mann, B.P., Schmitz, T.L., Peters, D.A., Stepan, G., Insperger, T.: Effects of radial immersion and cutting direction on chatter instability in end-milling. In: American Society of Mechanical Engineers, vol. 13, pp. 351–363. Manufacturing Engineering Division, MED (2002)

Bayly, P.V., Halley, J.E., Mann, B.P., Davies, M.A.: Stability of interrupted cutting by temporal finite element analysis. In: Proceedings of the ASME Design Engineering Technical Conference, vol. 6C, pp. 2361–2370 (2001)

Insperger, T., Stepan, G.: Semi-discretization method for delayed systems. Int. J. Numer. Methods Biomed. Eng. 55(5), 503–518 (2002)

Insperger, T., Stepan, G.: Updated semi-discretization method for periodic delay-differential equations with discrete delay. Int. J. Numer. Methods Biomed. Eng. 61(1), 117–141 (2004)

Gradisek, J., Kalveram, M., Insperger, T., Weinert, K., Stepan, G., Govekar, E., Grabec, I.: On stability prediction for milling. Int. J. Mach. Tools Manuf. 45, 769–781 (2005)

Long, X.-H., Balachandran, B.: Stability analysis for milling process. Nonlinear Dyn. 49(3), 349–395 (2007)

Ding, Y., Zhu, L.M., Zhang, X.J., Ding, H.: A full-discretization method for prediction of milling stability. Int. J. Mach. Tools Manuf. 50(5), 502–509 (2010)

Ding, Y., Zhu, L.M., Zhang, X.J., Ding, H.: Second-order full-discretization method for milling stability prediction. Int. J. Mach. Tools Manuf. 50, 926–932 (2010)

Insperger, T.: Full-discretization and semi-discretization for milling stability prediction: Some comments. Int. J. Mach. Tools Manuf. 50, 658–662 (2010)

Insperger, T., Stepan, G.: Semi-discretization for Time-Delay Systems. Springer, New York (2011)

Butcher, E.A., Ma, H., Bueler, E., Averina, V., Szabo, Zs.: Stability of time-periodicdelay-differential equations via Chebyshev polynomials. Int. J. Numer. Methods Eng. 59(7), 895–922 (2004)

Compean, F.I., Olvera, D., Campa, F.J., Lopez de Lacalle, L.N., Elias-Zuniga, A., Rodriguez, C.A.: Characterization and stability analysis of a multivariable milling tool by the enhanced multistage homotopy perturbation method. Int. J. Mach. Tools Manuf. 57, 27–33 (2012)

Long, X.-H., Balachandran, B., Mann, B.P.: Dynamics of milling processes with variable time delays. Nonlinear Dyn. 47(1–3), 49–63 (2007)

Wan, M., Wang, Y.T., Zhang, W.H., Yang, Y., Dang, J.W.: Prediction of chatter stability for multiple-delay milling system under different cutting force models. Int. J. Mach. Tools Manuf. 51, 281–295 (2011)

Ahmadi, K., Ismail, F.: Stability lobes in milling including process damping and utilizing multi-frequency and semi-discretization methods. Int. J. Mach. Tools Manuf. 54–55, 46–54 (2012)

Insperger, T., Stepan, G., Turi, J.: State-dependent delay in regenerative turning processes. Nonlinear Dyn. 47(1–3), 415–427 (2009)

Acknowledgements

This work is supported by National Natural Science Foundation of China (NSFC) under Grant No. 50975110 and Grant No. 51121002. It is also supported by The Leading Talent Project of Guangdong Province.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

Rights and permissions

About this article

Cite this article

Li, M., Zhang, G. & Huang, Y. Complete discretization scheme for milling stability prediction. Nonlinear Dyn 71, 187–199 (2013). https://doi.org/10.1007/s11071-012-0651-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11071-012-0651-4