Abstract

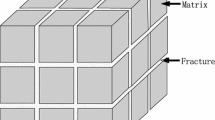

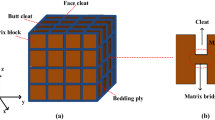

Fracture compressibility and strain boundary conditions are key factors in the evolution of coal permeability. Previous research has shown that fracture compressibility of coal is variable. Generally, the uniaxial strain condition is adopted for field coalbed methane (CBM) recovery. In this study, we assumed that the coal samples were under triaxial strain conditions combined with McKee’s stress-dependent fracture compressibility function and the improved Shi-Durucan permeability model. A new permeability model, with variable fracture compressibility, was derived. Considering variable fracture compressibility, the calculated results of the model were closer to the experimental values than the model with constant fracture compressibility. Based on previous experimental data, the responses of fracture compressibility to effective stress, gas pressure, gas type, and coal rank were analyzed. Coal fracture compressibility generally decreased with increase in effective stress. With increasing pore pressure, coal fracture compressibility first decreased and then increased when the experimental gas was CO2, CH4, or N2; it first increased and then decreased when the experimental gas was He. The stronger the adsorption capacity of the gas, the greater the coal fracture compressibility under uniform pore pressure. Numerical results of CBM production can be more accurate when the uniaxial and triaxial strain conditions are assumed for a coal seam far away from and near a wellhead, respectively.

Similar content being viewed by others

References

Busch, A., Krooss, B. M., Gensterblum, Y., Van Bergen, F., & Pagnier, H. J. M. (2003). High-pressure adsorption of methane, carbon dioxide and their mixtures on coals with a special focus on the preferential sorption behaviour. Journal of Geochemical Exploration, 78–79(03), 671–674. https://doi.org/10.1016/S0375-6742(03)00122-5.

Chen, D., Pan, Z., Ye, Z., Hou, B., Wang, D., & Yuan, L. (2016). A unified permeability and effective stress relationship for porous and fractured reservoir rocks. Journal of Natural Gas Science and Engineering, 29, 401–412. https://doi.org/10.1016/j.jngse.2016.01.034.

Chen, T., Feng, X. T., Cui, G., Tan, Y., & Pan, Z. (2019). Experimental study of permeability change of organic-rich gas shales under high effective stress. Journal of Natural Gas Science and Engineering, 64(January), 1–14. https://doi.org/10.1016/j.jngse.2019.01.014.

Connell, L. D., & Detournay, C. (2009). Coupled flow and geomechanical processes during enhanced coal seam methane recovery through CO2 sequestration. International Journal of Coal Geology, 77(1–2), 222–233. https://doi.org/10.1016/j.coal.2008.09.013.

Cui, X., & Bustin, R. M. (2005). Volumetric strain associated with methane desorption and its impact on coalbed gas production from deep coal seams. AAPG Bulletin, 89(9), 1181–1202. https://doi.org/10.1306/05110504114.

Gensterblum, Y., Ghanizadeh, A., & Krooss, B. M. (2014). Gas permeability measurements on Australian subbituminous coals: Fluid dynamic and poroelastic aspects. Journal of Natural Gas Science and Engineering, 19, 202–214. https://doi.org/10.1016/j.jngse.2014.04.016.

Gray, I. (1987). Reservoir engineering in coal seams: part 1 - the physical process of gas storage and movement in coal seams. SPE Reservoir Engineering (Society of Petroleum Engineers), 2(1), 28–34. https://doi.org/10.2118/12514-pa.

Harpalani, S., & Chen, G. (1997). Influence of gas production induced volumetric strain on permeability of coal. Geotechnical and Geological Engineering, 15(4), 303–325. https://doi.org/10.1007/bf00880711.

Huy, P. Q., Sasaki, K., Sugai, Y., & Ichikawa, S. (2010). Carbon dioxide gas permeability of coal core samples and estimation of fracture aperture width. International Journal of Coal Geology, 83(1), 1–10. https://doi.org/10.1016/j.coal.2010.03.002.

Laubach, S. E., Marrett, R. A., Olson, I. E., & Scott, A. R. (1998). Characteristics and origins of coal cleat: A review. International Journal of Coal Geology, 35(1–4), 175–207. https://doi.org/10.1016/S0166-5162(97)00012-8.

Li, J., Liu, D., Yao, Y., Cai, Y., & Chen, Y. (2013a). Evaluation and modeling of gas permeability changes in anthracite coals. Fuel, 111(September), 606–612. https://doi.org/10.1016/j.fuel.2013.03.063.

Li, S., Tang, D., Pan, Z., Xu, H., & Huang, W. (2013b). Characterization of the stress sensitivity of pores for different rank coals by nuclear magnetic resonance. Fuel, 111, 746–754. https://doi.org/10.1016/j.fuel.2013.05.003.

Li, J., Liu, D., Yao, Y., Cai, Y., Xu, L., & Huang, S. (2014). Control of CO2 permeability change in different rank coals during pressure depletion: An experimental study. Energy & Fuels, 28(2), 987–996. https://doi.org/10.1021/ef402285n.

Liu, J., Chen, Z., Elsworth, D., Miao, X., & Mao, X. (2010). Evaluation of stress-controlled coal swelling processes. International Journal of Coal Geology, 83(4), 446–455. https://doi.org/10.1016/j.coal.2010.06.005.

Liu, J., Chen, Z., Elsworth, D., Qu, H., & Chen, D. (2011a). Interactions of multiple processes during CBM extraction: A critical review. International Journal of Coal Geology, 87(3–4), 175–189. https://doi.org/10.1016/j.coal.2011.06.004.

Liu, J., Wang, J., Chen, Z., Wang, S., Elsworth, D., & Jiang, Y. (2011b). Impact of transition from local swelling to macro swelling on the evolution of coal permeability. International Journal of Coal Geology, 88(1), 31–40. https://doi.org/10.1016/j.coal.2011.07.008.

Liu, T., Lin, B., & Yang, W. (2017). Impact of matrix–fracture interactions on coal permeability: Model development and analysis. Fuel, 207, 522–532. https://doi.org/10.1016/j.fuel.2017.06.125.

Liu, T., Liu, S., Lin, B., Fu, X., Zhu, C., Yang, W., et al. (2020). Stress response during in situ gas depletion and its impact on permeability and stability of CBM reservoir. Fuel, 266(December 2019), 117083. https://doi.org/10.1016/j.fuel.2020.117083.

Ma, Q., Harpalani, S., & Liu, S. (2011). A simplified permeability model for coalbed methane reservoirs based on matchstick strain and constant volume theory. International Journal of Coal Geology, 85(1), 43–48. https://doi.org/10.1016/j.coal.2010.09.007.

Masoudian, M. S., Airey, D. W., & El-Zein, A. (2014). Experimental investigations on the effect of CO2 on mechanics of coal. International Journal of Coal Geology, 128–129, 12–23. https://doi.org/10.1016/j.coal.2014.04.001.

McKee, C. R., Bumb, A. C., & Koenig, R. A. (1988). Stress-dependent permeability and porosity of coal and other geologic formations. SPE Formation Evaluation, 3(1), 81–91. https://doi.org/10.2118/12858-PA.

Meng, Z., & Li, G. (2013). Experimental research on the permeability of high-rank coal under a varying stress and its influencing factors. Engineering Geology, 162, 108–117. https://doi.org/10.1016/j.enggeo.2013.04.013.

Meng, Y., & Li, Z. P. (2015). Experimental study on the porosity and permeability of coal in net confining stress and its stress sensitivity. Meitan Xuebao/Journal of the China Coal Society, 40(1), 154–159. https://doi.org/10.13225/j.cnki.jccs.2013.1518.

Meng, Y., & Li, Z. (2018). Experimental comparisons of gas adsorption, sorption induced strain, diffusivity and permeability for low and high rank coals. Fuel, 234(29), 914–923. https://doi.org/10.1016/j.fuel.2018.07.141.

Meng, Y., Li, Z., & Lai, F. (2015). Experimental study on porosity and permeability of anthracite coal under different stresses. Journal of Petroleum Science and Engineering, 133, 810–817. https://doi.org/10.1016/j.petrol.2015.04.012.

Meng, Y., Liu, S., & Li, Z. (2018). Experimental study on sorption induced strain and permeability evolutions and their implications in the anthracite coalbed methane production. Journal of Petroleum Science and Engineering, 164(29), 515–522. https://doi.org/10.1016/j.petrol.2018.01.014.

Moore, T. A. (2012). Coalbed methane: A review. International Journal of Coal Geology, 101, 36–81. https://doi.org/10.1016/j.coal.2012.05.011.

Palmer, I. (2009). Permeability changes in coal: Analytical modeling. International Journal of Coal Geology, 77(1–2), 119–126. https://doi.org/10.1016/j.coal.2008.09.006.

Palmer, I., & Mansoori, J. (1998). How permeability depends on stress and pore pressure a new model. Langmuir, 1(6), 539–544.

Pan, Z., & Connell, L. D. (2009). Comparison of adsorption models in reservoir simulation of enhanced coalbed methane recovery and CO2 sequestration in coal. International Journal of Greenhouse Gas Control, 3(1), 77–89. https://doi.org/10.1016/j.ijggc.2008.05.004.

Pan, Z., & Connell, L. D. (2011). Modelling of anisotropic coal swelling and its impact on permeability behaviour for primary and enhanced coalbed methane recovery. International Journal of Coal Geology, 85(3–4), 257–267. https://doi.org/10.1016/j.coal.2010.12.003.

Pan, Z., & Connell, L. D. (2012). Modelling permeability for coal reservoirs: A review of analytical models and testing data. International Journal of Coal Geology, 92, 1–44. https://doi.org/10.1016/j.coal.2011.12.009.

Peng, S., Fang, Z., Shen, J., Xu, J., & Wang, G. (2017a). Effects of gas sorption-induced swelling/shrinkage on the cleat compressibility of coal under different bedding directions. Scientific Reports, 7(1), 1–10. https://doi.org/10.1038/s41598-017-14678-1.

Peng, Y., Liu, J., Pan, Z., Connell, L. D., Chen, Z., & Qu, H. (2017b). Impact of coal matrix strains on the evolution of permeability. Fuel, 189, 270–283. https://doi.org/10.1016/j.fuel.2016.10.086.

Seidle, John P., & Huitt, L. G. (1995). Experimental measurement of coal matrix shrinkage due to gas desorption and implications for cleat permeability increases. Proceedings of the International Meeting on Petroleum Engineering, 2, 575–582. https://doi.org/10.2523/30010-ms.

Seidle, J. P., Jeansonne, M. W., & Erickson, D. J. (1992). Application of matchstick geometry to stress dependent permeability in coals. Society of Petroleum Engineers. https://doi.org/10.2523/24361-ms.

Shi, J. Q., & Durucan, S. (2004). Drawdown induced changes in permeability of coalbeds: A new interpretation of the reservoir response to primary recovery. Transport in Porous Media, 56(1), 1–16. https://doi.org/10.1023/B:TIPM.0000018398.19928.5a.

Shi, J. Q., & Durucan, S. (2010). Exponential growth in San Juan Basin fruitland coalbed permeability with reservoir drawdown: Model match and new insights. SPE Reservoir Evaluation & Engineering, 13(6), 914–925. https://doi.org/10.2118/123206-PA.

Shi, Ji Quan, Pan, Z., & Durucan, S. (2014). Analytical models for coal permeability changes during coalbed methane recovery: Model comparison and performance evaluation. International Journal of Coal Geology, 136, 17–24. https://doi.org/10.1016/j.coal.2014.10.004.

Tan, Y., Pan, Z., Feng, X. T., Zhang, D., Connell, L. D., & Li, S. (2019). Laboratory characterisation of fracture compressibility for coal and shale gas reservoir rocks: A review. International Journal of Coal Geology, 204(January), 1–17. https://doi.org/10.1016/j.coal.2019.01.010.

Vishal, V., Ranjith, P. G., & Singh, T. N. (2015). An experimental investigation on behaviour of coal under fluid saturation, using acoustic emission. Journal of Natural Gas Science and Engineering, 22, 428–436. https://doi.org/10.1016/j.jngse.2014.12.020.

Zhang, H., Liu, J., & Elsworth, D. (2008). How sorption-induced matrix deformation affects gas flow in coal seams: A new FE model. International Journal of Rock Mechanics and Mining Sciences, 45(8), 1226–1236. https://doi.org/10.1016/j.ijrmms.2007.11.007.

Zhang, S., Tang, S., Wan, Y., Li, Z., & Zhang, J. (2012). The migration of CH4 and CO2 in Jincheng anthracite coal. Journal of China University of Mining & Technology, 41(5), 770–775.

Zhang, J., Wei, C., Ju, W., Yan, G., Lu, G., Hou, X., et al. (2019a). Stress sensitivity characterization and heterogeneous variation of the pore-fracture system in middle-high rank coals reservoir based on NMR experiments. Fuel, 238(July 2018), 331–344. https://doi.org/10.1016/j.fuel.2018.10.127.

Zhang, J., Wei, C., Zhao, J., Ju, W., Chen, Y., & Tamehe, L. S. (2019b). Comparative evaluation of the compressibility of middle and high rank coals by different experimental methods. Fuel, 245(February), 39–51. https://doi.org/10.1016/j.fuel.2019.01.052.

Zheng, G., Pan, Z., Chen, Z., Tang, S., Connell, L., Zhang, S., et al. (2012). Laboratory study of gas permeability and cleat compressibility for CBM/ECBM in Chinese coals. Energy Exploration & Exploitation, 30(3), 451–476. https://doi.org/10.1260/0144-5987.30.3.451.

Zhu, J., Zhang, M., Jiang, Y. D., & Tang, J. (2015). Experimental study of coal strain induced by carbon dioxide sorption/desorption. Meitan Xuebao/Journal of the China Coal Society, 40(5), 1081–1086. https://doi.org/10.13225/j.cnki.jccs.2014.0967.

Zhu, J., Tang, J., Wang, Q., Lan, T., Lin, L., & Jiang, Y. (2019a). Study on the correlation between permeability and strain of coal samples under loading. Journal of China Coal Society. https://doi.org/10.13225/j.cnki.jccs.2019.1095.

Zhu, J., Tang, J., Wang, Q., Wang, Q., Zhang, B., & Zhang, B. (2019b). Modeling and experimental analysis on the permeability evolution of coal containing methane. Journal of China Coal Society, 44(6), 1764–1770.

Zou, J., Chen, W., Yang, D., Yu, H., & Yuan, J. (2016). The impact of effective stress and gas slippage on coal permeability under cyclic loading. Journal of Natural Gas Science and Engineering, 31, 236–248. https://doi.org/10.1016/j.jngse.2016.02.037.

Acknowledgments

This research was supported by the National Nature Science Foundation of China (52074297) and the Fundamental Research Funds for the Central Universities (2020YJSLJ06). We thank LetPub for its linguistic assistance during the preparation of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tang, J., Zhu, J., Shao, T. et al. A Coal Permeability Model with Variable Fracture Compressibility Considering Triaxial Strain Condition. Nat Resour Res 30, 1577–1595 (2021). https://doi.org/10.1007/s11053-020-09793-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11053-020-09793-2