Abstract

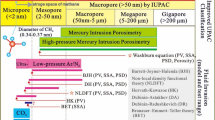

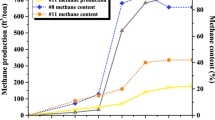

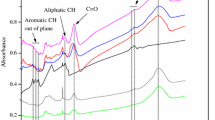

Better understanding of the storage and transportation characteristics of methane in coal seams is important to further develop and utilize the methane resources in the coalbed. This study is devoted to investigating the relationship between methane adsorption performance and pore structure by analyzing twelve coal samples derived from the typical methane-rich coalbeds in China. To eliminate the influence of inorganic components such as ash in different coal samples, a specific fixed-bed reactor with internals was employed for the coal treatment. Based on N2/CO2 adsorption analysis at low-pressure condition, the pores in coal were classified into three types in this study: ultra-micropore (pore width < 1 nm), micropore (1 nm < pore width < 2 nm) and mesopores (2 nm < pore width < 50 nm). According to the Langmuir equation, the Langmuir volume (VL) and Langmuir pressure (PL) were calculated to characterize the high-pressure adsorption of methane, and the influence of methane adsorption associated parameters was evaluated. The results indicate that N2-pore size distributions (1–50 nm) varied a lot among samples, suggesting the significant heterogeneity of pore structure among samples. Estimated by the FHH model, pore surface fractal dimension (D1) and spatial geometry fractal dimension (D2) were, respectively, ranging in 2.059–2.808 and 2.649–2.852, which indicated that the more irregular surface, namely more inhomogeneous pore structures, resulted in the more surface area and stronger adsorption capability. By grey relational analysis (GRA), the importance of the pore structure factors on methane adsorption was identified, as an order from the most important to the least: ultra-micropore volume (0.9085) > ultra-micropore surface area (0.8976) > fractal dimension D1 (0.8862) > N2-BET surface area (0.7915) > micropore volume (0.5035) > micropore surface area (0.5006). This study shows the influence of parameters of pore structure on methane adsorption of coal and clarifies the order importance of these parameters by the GRA method.

Similar content being viewed by others

References

Behar, F., & Hatcher, P. G. (1995). Artificial coalification of a fossil wood from brown coal by confined system pyrolysis. Energy & Fuels, 9(6), 984–994.

Bustin, R. M., & Clarkson, C. R. (1998). Geological controls on coalbed methane reservoir capacity and gas content. International Journal of Coal Geology, 38(1–2), 3–26.

Cai, Y., Liu, D., Pan, Z., Yao, Y., Li, J., & Qiu, Y. (2013). Pore structure and its impact on CH4 adsorption capacity and flow capability of bituminous and subbituminous coals from Northeast China. Fuel, 103, 258–268.

Clarkson, C. R., & Marc Bustin, R. (1996). Variation in micropore capacity and size distribution with composition in bituminous coal of the Western Canadian Sedimentary Basin. Fuel, 75(13), 1483–1498.

Clarkson, C. R., Solano, N., Bustin, R. M., Bustin, A. M. M., Chalmers, G. R. L., He, L., et al. (2013). Pore structure characterization of North American shale gas reservoirs using USANS/SANS, gas adsorption, and mercury intrusion. Fuel, 103, 606–616.

De Jonge, H., & Mittelmeijer-Hazeleger, M. C. (1996). Adsorption of CO2 and N2 on Soil Organic Matter: Nature of Porosity, Surface Area, and Diffusion Mechanisms. Environmental Science and Technology, 30(2), 408–413.

Everett, D. H. (1972). Manual of symbols and terminology for physicochemical quantities and units, appendix II: definitions, terminology and symbols in colloid and surface chemistry. Pure and Applied Chemistry, 31(4), 577–638.

Fan, J., Liu, P., Li, J., & Jiang, D. (2020). A coupled methane/air flow model for coal gas drainage: model development and finite-difference solution. Process Safety and Environmental Protection, 141, 288–304.

Genty, C., Jensen, J. L., & Ahr, W. M. (2007). Distinguishing carbonate reservoir pore facies with nuclear magnetic resonance measurements. Natural Resources Research, 16(1), 45–54.

Gorbaty, M. L., Mraw, S. C., Gethner, J. S., & Brenner, D. (1986). Coal physical structure: porous rock and macromolecular network. Fuel Processing Technology, 12, 31–49.

Hao, S., Wen, J., Yu, X., & Chu, W. (2013). Effect of the surface oxygen groups on methane adsorption on coals. Applied Surface Science, 264, 433–442.

Harris, L., & Yust, C. (1976). Transmission electron microscope observations of porosity in coal. Fuel, 55(3), 233–236.

Hu, E., Zeng, X., Wang, F., Li, Y., Yi, X., & Fu, X. (2017). Effects of metallic heating plates on coal pyrolysis behavior in a fixed-bed reactor enhanced with internals. Energy & Fuels, 31(3), 2716–2721.

Jagiello, J., Ania, C., Parra, J. B., & Cook, C. (2015). Dual gas analysis of microporous carbons using 2D-NLDFT heterogeneous surface model and combined adsorption data of N2 and CO2. Carbon, 91, 330–337.

Landais, P. (1991). Assessment of coal potential evolution by experimental simulation of natural coalification. Organic Geochemistry, 17(6), 705–710.

Langmuir, I. (1918). The adsorption of gases on plane surfaces of glass, mica and platinum. Journal of the American Chemical Society, 40(9), 1361–1403.

Levy, J. H., Day, S. J., & Killingley, J. S. (1997). Methane capacities of Bowen Basin coals related to coal properties. Fuel, 76(9), 813–819.

Li, X., Li, Z., Wang, E., Liang, Y., Li, B., & Liu, Y. (2018). Pattern recognition of mine microseismic (MS) and blasting events based on wave fractal features. Fractals, 26(03), 1850029. https://doi.org/10.1142/s0218348x18500299.

Liu, X., & He, X. (2017). Effect of pore characteristics on coalbed methane adsorption in middle-high rank coals. Adsorption, 23(1), 3–12.

Liu, S., Li, X., Wang, D., Wu, M., Yin, G., & Li, M. (2019). Mechanical and acoustic emission characteristics of coal at temperature impact. Natural Resources Research, 4, 1–18.

Liu, X., & Nie, B. (2016). Fractal characteristics of coal samples utilizing image analysis and gas adsorption. Fuel, 182, 314–322.

Macuda, J., Baran, P., & Wagner, M. (2020). Evaluation of the presence of methane in złoczew lignite comparison with other lignite deposits in Poland. Natural Resources Research. https://doi.org/10.1007/s11053-020-09691-7.

Mahajan, O. P. (1991). CO2 surface area of coals: The 25-year paradox. Carbon, 29(6), 735–742.

Mastalerz, M., Drobniak, A., & Rupp, J. (2008). Meso-and micropore characteristics of coal lithotypes: implications for CO2 adsorption. Energy & Fuels, 22(6), 4049–4061.

Mastalerz, M., Gluskoter, H., & Rupp, J. (2004). Carbon dioxide and methane sorption in high volatile bituminous coals from Indiana, USA. International Journal of Coal Geology, 60(1), 43–55.

Mastalerz, M., He, L., Melnichenko, Y. B., & Rupp, J. A. (2012). Porosity of coal and shale: insights from gas adsorption and SANS/USANS techniques. Energy & Fuels, 26(8), 5109–5120.

Matranga, K. R., Myers, A. L., & Glandt, E. D. (1992). Storage of natural gas by adsorption on activated carbon. Chemical Engineering Science, 47(7), 1569–1579.

Nelabhotla, D. M., Jayaraman, T. V., Asghar, K., & Das, D. (2016). The optimization of chemical mechanical planarization process-parameters of c-plane gallium-nitride using Taguchi method and grey relational analysis. Materials and Design, 104, 392–403.

Nguyen, T. X., & Bhatia, S. K. (2007). Pore accessibility of N2 and Ar in disordered nanoporous solids: theory and experiment. Adsorption, 13(3–4), 307–314.

Nie, B., Liu, X., Yang, L., Meng, J., & Li, X. (2015). Pore structure characterization of different rank coals using gas adsorption and scanning electron microscopy. Fuel, 158, 908–917.

Okolo, G. N., Everson, R. C., Neomagus, H. W. J. P., Roberts, M. J., & Sakurovs, R. (2015). Comparing the porosity and surface areas of coal as measured by gas adsorption, mercury intrusion and SAXS techniques. Fuel, 141, 293–304.

Shen, J., Sulkowski, J., Beckner, M., & Dailly, A. (2015). Effects of textural and surface characteristics of metal-organic frameworks on the methane adsorption for natural gas vehicular application. Microporous and Mesoporous Materials, 212, 80–90.

Sun, W., Feng, Y., Jiang, C., & Chu, W. (2015). Fractal characterization and methane adsorption features of coal particles taken from shallow and deep coalmine layers. Fuel, 155, 7–13.

Thommes, M. (2010). Physical adsorption characterization of nanoporous materials. Chemie Ingenieur Technik, 82(7), 1059–1073.

Walker, P. L., & Mahajan, O. P. (1993). Pore structure in coals. Energy & Fuels, 7(4), 559–560.

Wang, Y., Zhu, Y., Liu, S., & Zhang, R. (2016). Pore characterization and its impact on methane adsorption capacity for organic-rich marine shales. Fuel, 181, 227–237.

Xu, S., Han, Z., Wu, R., Cheng, J., & Xu, G. (2018a). Correlating micro/meso pore evolution and chemical structure variation in a mild thermal treatment of a subbituminite. RSC Advances, 8(18), 9754–9761.

Xu, S., Lai, D., Zeng, X., Zhang, L., Han, Z., Cheng, J., et al. (2018b). Pyrolysis characteristics of waste tire particles in fixed-bed reactor with internals. Carbon Resources Conversion, 1(3), 228–237.

Xu, G., Yang, Y.-P., Lu, S.-Y., Li, L., & Song, X. (2011). Comprehensive evaluation of coal-fired power plants based on grey relational analysis and analytic hierarchy process. Energy Policy, 39(5), 2343–2351.

Xu, S., Zeng, X., Han, Z., Cheng, J., Wu, R., Chen, Z., et al. (2019). Quick pyrolysis of a massive coal sample via rapid infrared heating. Applied Energy, 242, 732–740.

Yang, R. T., & Saunders, J. T. (1985). Adsorption of gases on coals and heat treated coals at elevated temperature and pressure. Fuel, 64(5), 616–620.

Yao, Y., Liu, D., Tang, D., Tang, S., & Huang, W. (2008). Fractal characterization of adsorption-pores of coals from North China: An investigation on CH4 adsorption capacity of coals. International Journal of Coal Geology, 73(1), 27–42.

Yao, Y., Liu, D., & Xie, S. (2014). Quantitative characterization of methane adsorption on coal using a low-field NMR relaxation method. International Journal of Coal Geology, 131, 32–40.

Zhang, Y., Lebedev, M., Smith, G., Jing, Y., Busch, A., & Iglauer, S. (2019a). Nano-mechanical properties and pore-scale characterization of different rank coals. Natural Resources Research, 29(3), 1787–1800.

Zhang, K., Wang, L., Cheng, Y., Li, W., Kan, J., Tu, Q., et al. (2019b). Geological control of fold structure on gas occurrence and its implication for coalbed gas outburst: case study in the qinan coal mine, huaibei coalfield. China. Natural Resources Research, 29(2), 1375–1395.

Zhao, Y., Liu, S., Elsworth, D., Jiang, Y., & Zhu, J. (2014). Pore structure characterization of coal by synchrotron small-angle X-ray scattering and transmission electron microscopy. Energy & Fuels, 28(6), 3704–3711.

Zuo, W. E. J., Liu, X., Peng, Q., Deng, Y., & Zhu, H. (2016). Orthogonal experimental design and fuzzy grey relational analysis for emitter efficiency of the micro-cylindrical combustor with a step. Applied Thermal Engineering, 103, 945–951.

Acknowledgments

The study was financially supported by National Science and Technology Major Project of China (2016ZX05040-003). We thank Doctor Nie Fan for his linguistic assistance during the revise of this manuscript.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Xu, S., Hu, E., Li, X. et al. Quantitative Analysis of Pore Structure and Its Impact on Methane Adsorption Capacity of Coal. Nat Resour Res 30, 605–620 (2021). https://doi.org/10.1007/s11053-020-09723-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11053-020-09723-2