Abstract

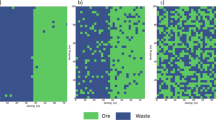

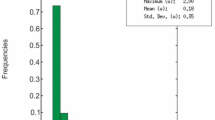

Grade control and short-term planning determine the performance of a mining project. Improving this decision, by collecting the most informative samples (data) may have significant financial impact on the project. In this paper, a method to select sampling locations is proposed in an advanced drilling grid for short-term planning and grade control in order to improve the correct assessment (ore-waste discrimination) of blocks. The sampling strategy is based on a regularized maximization of the conditional entropy of the field, functional that formally combines global characterization of the field with the principle of maximizing information extraction for ore-waste discrimination. This sampling strategy is applied to three real cases, where dense blast-hole data is available for validation from several benches. Remarkably, results show relevant and systematic improvement with respect to the standard regular grid strategy, where for deeper benches in the field the gains in ore-waste discrimination are more prominent.

Similar content being viewed by others

References

Abzalov, M. Z., Menzel, B., Wlasenko, M., & Phillips, J. (2010). Optimisation of the grade control procedures at the yandi iron-ore mine, western australia: Geostatistical approach. Applied Earth Science, 119(3), 132–142. https://doi.org/10.1179/1743275811Y.0000000007.

Blackwell, G. (1998). Relative kriging errors—a basis for mineral resource classification. Exploration Mining Geology, 7, 99–105.

Boisvert, J. B., Leuangthong, O., Ortiz, J. M., & Deutsch, C. V. (2008). A methodology to construct training images for vein type deposits. Computers & Geosciences, 34(5), 491–502.

Chiles, J. P., & Delfiner, P. (2012). Geostatistics: Modeling spatial uncertainty (2nd ed.). Hoboken: Wiley.

Cover, T. M., & Thomas, J. A. (2006). Elements of information theory (2nd ed.). New York: Wiley.

Deutsch, C. V., & Journel, A. G. (1998). GSLIB—geostatistical software library and user’s guide. Oxford: Oxford University Press.

Deutsch, C. V., Magri, E., & Norrena, K. (2000). Optimal grade control using geostatistics and economics: methodology and examples. Society of Mining Engineers SME Transactions Transactions, 308, 43–52.

Dimitrakopoulos, R., & Godoy, M. (2014). Grade control based on economic ore/waste classification functions and stochastic simulations: Examples, comparisons and applications. Mining Technology, 123(2), 90–106. https://doi.org/10.1179/1743286314Y.0000000062.

Francois-Bongarcon, D. (1983). The practice of sampling of broken ores. Canadian Institute of Mining, Metallurgy & Petroleum CIM Bulletin, 86(970), 75–81.

Hassanipak, A. A., & Sharafodin, M. (2004). GET: A function for preferential site selection of additional borehole drilling. Exploration & Mining Geology, 13(1–4), 139–146.

Journel, A., & Kyriakidis, P. C. (2004). Evaluation of mineral reserves—a simulation approach. Oxford: Oxford University Press.

Journel, A. G. (1974). Geostatistics for conditional simulation of ore bodies. Economic Geology, 69, 673–687.

Kumral, M. (2012). Production planning of mines: Optimisation of block sequencing and destination. International Journal of Mining, Reclamation and Environment, 26(2), 93–103. https://doi.org/10.1080/17480930.2011.644474.

Kumral, M. (2013). Optimizing ore-waste discrimination and block sequencing through simulated annealing. Applied Soft Computing, 13(8), 3737–3744. https://doi.org/10.1016/j.asoc.2013.03.005.

Lloyd, C., & Atkinson, P. (1998). Scale and the spatial structure of landform: Optimising sampling strategies with geostatistics. In Proceedings of the 3rd international conference on geoComputation. University of Leeds.

Magri, E., & Ortiz, J. (2000). Estimation of economic losses due to poor blast hole sampling in open pits. In Geostatistics 2000, Proceedings of the 6th international geostatistics congress. Cape Town, South Africa, vol. 2, pp. 732–741.

Magri, E., Ortiz, J., & Libano, R. (2010). The economic optimisation of advanced drilling grids for short term planning and grade control at El Tesoro copper mine. In MININ 2010, Proceedings of the 4th international conference on mining innovation. Santiago, Chile, pp. 89–98.

Magri, E., Ortiz, J., Moya, R., & Salazar, A. (2011). Advanced reverse circulation drilling as a replacement to blasthole sampling: increasing short term planning profitability at cerro colorado copper mine. In 5th world conference on sampling and blending. Santiago, Chile.

Mariethoz, G., & Caers, J. (2014). Multiple-point geostatistics: Stochastic modeling with training images. Hoboken: Wiley.

McBratney, A., Webster, R., & Burgess, T. (1981). The design of optimal sampling schemes for local estimation and mapping of regionalized variables. i. theory and method. Computers and Geosciences, 7(4), 331–334.

McBratney, A., & Webster, R. (1981). The design of optimal sampling schemes for local estimation and mapping of regionalized variables. ii. program and examples. Computers and Geosciences, 7(4), 335–365.

Ortiz, J.M. (2003). Characterization of high order correlation for enhanced indicator simulation. Doctoral dissertation, University of Alberta.

Ortiz, J. M., & Deutsch, C. V. (2004). Indicator simulation accounting for multiple-point statistics. Mathematical Geology, 36(5), 545–565. https://doi.org/10.1023/B:MATG.0000037736.00489.b5.

Ortiz, J. M., & Magri, E. J. (2014). Designing an advanced RC drilling grid for short-term planning in open pits: Three case studies. Journal of the Southern African Institute of Mining and Metallurgy, 114, 631–637.

Ortiz, J. M., Magri, E., & Libano, R. (2012). Improving financial returns from mining through geostatistical simulation and the optimized advance drilling grid at el tesoro copper mine. Journal of the Southern African Institute of Mining and Metallurgy, 112(1), 15–22.

Pitard, F. (1993). Pierre Gy’s sampling theory and sampling practice. Heterogeneity, sampling correctness, and statistical process control (2nd ed.). Boca Raton: CRC Press.

Ruiseco, J. R., Williams, J., & Kumral, M. (2016). Optimizing ore-waste dig-limits as part of operational mine planning through genetic algorithms. Natural Resources Research, 25(4), 473–485. https://doi.org/10.1007/s11053-016-9296-1.

Santibañez, F., Silva, J. F., & Ortiz, J. M. (2019). Sampling strategies for uncertainty reduction in categorical random fields: Formulation, mathematical analysis and application to multiple-point simulations. Mathematical Geosciences, 51(5), 579–624. https://doi.org/10.1007/s11004-018-09777-2.

Silva Maureira, D.A. (2015). Enhanced geologic modeling with data-driven training images for improved resources and recoverable reserves. Doctoral dissertation, Ph.D. thesis, University of Alberta.

Vasát, R., Heuvelink, G., & Borúvka, L. (2010). Sampling design optimization for multivariate soil mapping. Geoderma, 155, 147–153.

Verly, G. (2005). Grade control classification of ore and waste: A critical review of estimation and simulation based procedures. Mathematical Geology, 37, 417–476.

Author information

Authors and Affiliations

Corresponding author

Additional information

The work was supported by the research grants Fondecyt 1170854, CONICYT, Chile. The work of Dr. Silva is supported by the Advanced Center for Electrical and Electronic Engineering (AC3E), Basal Project FB0008. Felipe Santibañez is supported by CONICYT Ph.D. scholarship 21130890 and the Advanced Mining Technology Center (AMTC) Basal project (CONICYT Project AFB180004). Dr. Ortiz acknowledges the support of the Natural Sciences and Engineering Council of Canada (NSERC), funding reference number RGPIN-2017-04200 and RGPAS-2017-507956.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Appendices

Appendix A: Pseudo-code

The implemented pseudo-code that summarizes the proposed framework is shown here.

Appendix B: Additional Experimental Results

Case study 1: Cut-off grade \(1.241\%\)

With Cut-off grade \(1.241\%\), Figures 10, 11, 12, and 13 describe the achieved outcome. Figure 13 provides a summary of the confusion matrices for case study 1 considering a Cut-off grade of 1.241%.

Case study 1: Cut-off grade \(1.518\%\)

Considering the Cut-off grade \(1.518\%\), the outcome for the benches 2, 3, 4, 5 and 6 is described in Figures 14, 15, 16, and, 17. The Figure 17 provide the performance summary in terms of the confussion matrices for case study 1 and Cut-off grade 1.518%.

Appendix C: Economic Evaluation

In order to perform a realistic evaluation of cost and profit, several considerations must be defined for the mining and waste processing. In particular, in this work the variables summarized in Table 10 have been considered, where a range of realistic values for these variables is proposed. This analysis takes into account the block size (fixed to 1000 \(\text {m}^\text {3}\), the same block size used in the experimental section), the mining cost by mined ton, the metallurgical recovery, and the stripping ratio (the proportion of tons of expected waste material and ore material). For the purpose of the present analysis, the economic costs considered were the processing cost by processed ton, the price and selling cost per pound of copper.

In practice, the Cut-off grade, Cg, can be defined by,

where the value 2204.6 corresponds to the conversion factor from pounds to tons.

Given the set of values for the considered parameters, it is possible to estimate the profit of a block. For a block with an estimated grade under the Cut-off grade value, for simplification it has been defined that the cost to process the waste block in the dump facilities is considered equal for each dumped block without taking into account its actual mineral grade or another variables. For this brief analysis, the revenue from dumping the block is zero (in practice if the block has a zero profit, since it has already been mined then it could be considered as stock pile). Thus:

In the case of a block estimated as ore (estimated block grade is above the Cut-off grade), it is processed by the mine and its benefit is calculated considering the content of metal in percentage of tons of copper as,

The content of recovered metal in tons of copper is estimated as

Then, the revenue from mining the block is estimated by,

while the processing cost of the block is estimated as

Finally, the profit of the processed block is defined by,

Therefore, from Eqs. 12 and 17 and the cost of processing ore and waste blocks, it is possible to estimate the profit or loss of any block.

Considering the Cut-off grade of the experimental analysis and Eq. 11, the appropriate economic parameters have been estimated. The initial values shown in Table 10 are provided as an example to obtain the Cut-off grade as the first quartile in Case Study 1. For each case study and for every empirical Cut-off grade, the best set of parameters has been estimated in order to perform the economic analysis.

Then, from the experimental data the profit of every block has been evaluated in the proposed scenarios for the sampling strategies under analysis. Given an estimated bench block model from a specific sampling strategy, the economic profit can be calculated as the sum of the profit for each block conforming this bench.

Rights and permissions

About this article

Cite this article

Santibáñez-Leal, F.A., Ortiz, J.M. & Silva, J.F. Ore-Waste Discrimination with Adaptive Sampling Strategy. Nat Resour Res 29, 3079–3102 (2020). https://doi.org/10.1007/s11053-020-09625-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11053-020-09625-3