Abstract

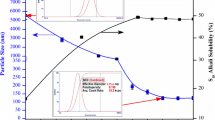

A simple route was designed to extract the cellulose nanocrystals (CNCs) with formate groups from industrial and agricultural celluloses like microcrystalline cellulose (MCC), viscose fiber, ginger fiber, and bamboo fiber. The effect of reaction time on the microstructure and properties of the CNCs was investigated in detail, while microstructure and properties of different CNCs were compared. The rod-like CNCs (MCC) with hundreds of nanometers in length and about 10 nm in width, nanofibrillated CNCs (ginger fiber bamboo fiber) with average width of 30 nm and the length of 1 μm, and spherical CNCs (viscose fiber) with the width of 56 nm were obtained by one-step HCOOH/HCl hydrolysis. The CNCs with improved thermal stability showed the maximum degradation temperature (T max) of 368.9–388.2 °C due to the introduction of formate groups (reducibility) and the increased crystallinity. Such CNCs may be used as an effective template for the synthesis of nanohybrids or reinforcing material for high-performance nanocomposites.

Similar content being viewed by others

References

Altaner CM et al (2014) Cellulose Iβ investigated by IR-spectroscopy at low temperatures. Cellulose 21:3171–3179

Bettaieb F et al (2015) Preparation and characterization of new cellulose nanocrystals from marine biomass Posidonia oceanica. Ind Crops Prod 72:175–182

Braun B, Dorgan JR (2009) Single-step method for the isolation and surface functionalization of cellulosic nanowhiskers. Biomacromolecules 10(2):334–341

Camarero Espinosa S et al (2013) Isolation of thermally stable cellulose nanocrystals by phosphoric acid hydrolysis. Biomacromolecules 14(4):1223–1230

Cherian BM et al (2008) A novel method for the synthesis of cellulose nanofibril whiskers from banana fibers and characterization. J Agric Food Chem 56(14):5617–5627

de Morais Teixeira E et al (2010) Cellulose nanofibers from white and naturally colored cotton fibers. Cellulose 17(3):595–606

Dong YY et al (2014) Compare study cellulose/Ag hybrids using fructose and glucose as reducing reagents by hydrothermal method. Carbohydr Polym 106:14–21

Elazzouzi-Hafraoui S et al (2008) The shape and size distribution of crystalline nanoparticles prepared by acid hydrolysis of native cellulose. Biomacromolecules 9(1):57–65

Fan JS, Li YH (2012) Maximizing the yield of nanocrystalline cellulose from cotton pulp fiber. Carbohydr Polym 88(4):1184–1188

Fortunati E et al (2012) Effects of modified cellulose nanocrystals on the barrier and migration properties of PLA nano-biocomposites. Carbohydr Polym 90(2):948–956

Haafiz MM et al (2013) Physicochemical characterization of cellulose nanowhiskers extracted from oil palm biomass microcrystalline cellulose. Mater Lett 113:87–89

Jiang F, Hsieh YL (2015) Cellulose nanocrystal isolation from tomato peels and assembled nanofibers. Carbohydr Polym 122:60–68

Khristova P, Kordsachia O, Khider T (2005) Alkaline pulping with additives of date palm rachis and leaves from Sudan. Bioresour Technol 96(1):79–85

Klemm D et al (2012) Fundamentals and analytical methods. In: Klemm D, Heinze T, Heinze U, Edgar KJ, Philipp B, Zugenmaier P (eds) Comprehensive cellulose chemistry. Wiley-VCH, Weinheim, pp 83–85

Lazko J et al (2014) Well defined thermostable cellulose nanocrystals via two-step ionic liquid swelling-hydrolysis extraction. Cellulose 21(6):4195–4207

Li MC et al (2015a) Cellulose nanoparticles: structure–morphology–rheology relationships. ACS Sustain Chem Eng 3(5):821–832

Li MC et al (2015b) Cellulose nanoparticles as modifiers for rheology and fluid loss in bentonite water-based fluids. ACS Appl Mater Interfaces 7(8):5006–5016

Lu P, Hsieh YL (2010) Preparation and properties of cellulose nanocrystals: rods, spheres, and network. Carbohydr Polym 82(2):329–336

Lu Q et al (2015) A mechanochemical approach to manufacturing bamboo cellulose nanocrystals. J Mater Sci 50(2):611–619

Martínez-Sanz M, Lopez-Rubio A, Lagaron JM (2011) Optimization of the nanofabrication by acid hydrolysis of bacterial cellulose nanowhiskers. Carbohydr Polym 85(1):228–236

Martins DF et al (2015) The influence of the cellulose hydrolysis process on the structure of cellulose nanocrystals extracted from capim mombaça (Panicum maximum). Ind Crops Prod 65:496–505

Pääkkö M et al (2007) Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromolecules 8(6):1934–1941

Saito T et al (2006) Homogeneous suspensions of individualized microfibrils from TEMPO-catalyzed oxidation of native cellulose. Biomacromolecules 7(6):1687–1691

Satyamurthy P, Vigneshwaran N (2013) A novel process for synthesis of spherical nanocellulose by controlled hydrolysis of microcrystalline cellulose using anaerobic microbial consortium. Enzyme Microb Technol 52(1):20–25

Satyamurthy P et al (2011) Preparation and characterization of cellulose nanowhiskers from cotton fibres by controlled microbial hydrolysis. Carbohydr Polym 83(1):122–129

Seehra MS et al (2014) Hydrothermal treatment of microcrystalline cellulose under mild conditions: characterization of solid and liquid-phase products. Cellulose 21(6):4483–4495

Segal L et al (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29(10):786–794

Shin Y et al (2007) Simple preparation and stabilization of nickel nanocrystals on cellulose nanocrystal. Mater Lett 61(14):3215–3217

Shin Y et al (2008) Facile stabilization of gold–silver alloy nanoparticles on cellulose nanocrystal. J Phys Chem C 112(13):4844–4848

Silvério HA et al (2013) Extraction and characterization of cellulose nanocrystals from corncob for application as reinforcing agent in nanocomposites. Ind Crops Prod 44:427–436

Tan C et al (2015) Role of surface modification and mechanical orientation on property enhancement of cellulose nanocrystals/polymer nanocomposites. Eur Polym J 62:186–197

Tang Y et al (2014) Preparation and characterization of nanocrystalline cellulose via low-intensity ultrasonic-assisted sulfuric acid hydrolysis. Cellulose 21(1):335–346

Wang N, Ding E, Cheng R (2007) Thermal degradation behaviors of spherical cellulose nanocrystals with sulfate groups. Polymer 48(12):3486–3493

Xu X et al (2013) Properties of novel polyvinyl alcohol/cellulose nanocrystals/silver nanoparticles blend membranes. Carbohydr Polym 98(2):1573–1577

Yan CF, Yu HY, Yao JM (2015) One-step extraction and functionalization of cellulose nanospheres from lyocell fibers with cellulose II crystal structure. Cellulose 22(6):3773–3788

Yu H et al (2013) Facile extraction of thermally stable cellulose nanocrystals with a high yield of 93% through hydrochloric acid hydrolysis under hydrothermal conditions. J Mater Chem A 1(12):3938–3944

Yu H et al (2014a) Reinforcement of biodegradable poly(3-hydroxybutyrate-co-3-hydroxyvalerate) with cellulose nanocrystal/silver nanohybrids as bifunctional nanofillers. J Mater Chem B 2(48):8479–8489

Yu H, Yan C, Yao J (2014b) Fully biodegradable food packaging materials based on functionalized cellulose nanocrystals/poly(3-hydroxybutyrate-co-3-hydroxyvalerate) nanocomposites. RSC Adv 4(104):59792–59802

Yu HY et al (2014c) A facile one-pot route for preparing cellulose nanocrystal/zinc oxide nanohybrids with high antibacterial and photocatalytic activity. Cellulose 22:261–273

Zaki FA, Abdullah I, Ahmad I (2014) The physical and chemical natures of cellulose extracted from torch ginger stems. Int J Mater Eng Innov 5(1):48–60

Zhang X et al (2014) Direct immobilization of antibodies on dialdehyde cellulose film for convenient construction of an electrochemical immunosensor. Sens Actuator B 200:304–309

Acknowledgments

This work was funded by State Key Laboratory for Modification of Chemical Fibers and Polymer Materials, Donghua University (LK1428), The National Natural Science Foundation of China (51403187), The Public Technology Research Plan of Zhejiang Province, China, under Grant No. 2015C33111, Zhejiang Provincial Natural Science Foundation of China under Grant No. LQ14E030007, “521” Talent Project of Zhejiang Sci-Tech University, and Open Fund in Top Priority Discipline of Zhejiang Province in Zhejiang Sci-Tech University (2015YXQN04, 2015YXQN11).

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Chen, GY., Yu, HY., Zhang, CH. et al. A universal route for the simultaneous extraction and functionalization of cellulose nanocrystals from industrial and agricultural celluloses. J Nanopart Res 18, 48 (2016). https://doi.org/10.1007/s11051-016-3355-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-016-3355-8