Abstract

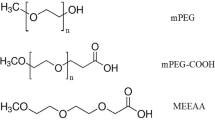

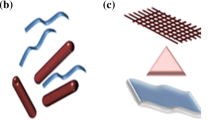

A convenient method to synthesize uniform, well-dispersed colloidal silver nanoparticles is described. Aldonic acid or α-hydroxy acid compounds of low molecular weight are used instead of polymeric compounds as dispersing agents to prepare silver nanoparticles. The size, conformation, and electrical conductivity of the silver nanoparticles, and the effect and function of the dispersing agents are investigated in detail. Using these low molecular weight compounds as dispersing agents, silver nanoparticles with a diameter of 10 nm or less and high electrical conductivity can be obtained. In addition, this procedure allows silver nanoparticles to be sintered at 150 °C, which is lower than that required for silver nanoparticle formulation using polymeric compounds (200 °C). The silver nanoparticles produced by this process can be used to prepare various inks and to manufacture electronic circuits. It is found that low molecular weight compounds are more effective dispersing agents than polymeric compounds in the formation of silver nanoparticles.

Similar content being viewed by others

Abbreviations

- XRD:

-

X-ray diffraction

- TEM:

-

Transmission electron microscopy

- EDS:

-

Energy dispersive X-ray spectroscopy

- SEM:

-

Scanning electron microscopy

- FT–IR:

-

Fourier transform infrared absorption spectroscopy

- C5H11O5COONa:

-

(2R,3S,4R,5R)-2,3,4,5,6-pentahydroxyhexanoate (also called sodium gluconate)

- AgNO3 :

-

Silver nitrate

- Na3Ct:

-

Trisodium 2-hydroxypropane-1, 2, 3-tricarboxylate

- DMAE:

-

2-(Dimethylamino) ethanol

- PVP:

-

Polyvinylpyrrolidone

- PVA:

-

Polyvinyl alcohol

References

Brust M, Walker M, Bethell D, Schiffrin DJ, Whyman R (1994) Synthesis of thiol-derivatised gold nanoparticles in a two-phase liquid–liquid dystem. J Chem Soc Chem Commun 1:801–802

Cho JW, So JH (2006) Polyurethane–silver fibers prepared by infiltration and reduction of silver nitrate. Mater Lett 60:2653–2656

Chou KS, Lai YS (2004) Effect of polyvinyl pyrrolidone molecular weights on the formation of nanosized silver colloids mater. Chem Phys 83:82–88

Hsu SLC, Wu RT (2007) Synthesis of contamination-free silver nanoparticle suspensions for micro-interconnects. Mater Lett 61:3719–3722

Klueh U, Wagner V, Kelly S, Johnson A, Bryers JD, Biomed J (2000) Efficacy of silver-coated fabric to prevent bacterial colonization and subsequent device-based biofilm formation. Mater Res 53:621–631

Lee H, Chou KS (2005) Inkjet printing of nanosized silver colloids. Nanotechnology 16:2411–2436

Lewis LN (1993) Chemical catalysis by colloids and clusters. Chem Rev 93:2693–2730

Natsuki J, Abe T (2011) Synthesis of pure colloidal silver nanoparticles with high electroconductivity for printed electronic circuits: the effect of amines on their formation in aqueous media. J Colloid Interface Sci 359:19–23

Pathak S, Greci MT, Kwong RC, Mercado K, Prakash OGA, Thompson ME (2000) Synthesis and applications of palladium-coated poly(vinylpyridine) nanospheres. Chem Mater 12:1689–1985

Radziuk D, Skirtach A, Sukhorukov GB, Shchukin DG, Möhwald H (2007) Stabilization of silver nanoparticles by polyelectrolytes and polyethylene glycol. Rapid Commun 28:848–855

Schmid G (1992) Large clusters and colloids. Metals in the embryonic state. Chem Rev 92:1709–1727

Sondi I, Goia DV, Matijevic E (2003) Preparation of highly concentrated stable dispersions of monodispersed silver nanoparticles. J Colloid Interface Sci 260:75–81

Tan Y, Dai X, Li Y, Zhu D (2003) Preparation of gold, platinum, palladium and silver nanoparticles by the reduction of their salts with a weak reductant—potassium bitartrate. J Mater Chem 13:1069–1075

Thomas JM (1988) Colloidal metals: past, present and future. Pure Appl Chem 60:1517–1528

Tsuruga S, Abe T (2008) Proceedings of the Pan-Pacific imaging conference, preparation of electro-conductive inkjet inks through silver halide photographic emulsion, Tokyo, Japan, p 56–59

Wang Y, Ren J, Deng K, Gui L, Tang Y (2000) Preparation of tractable platinum, rhodium, and ruthenium nanoclusters with small particle size in organic media. Chem Mater 12:1622–1627

Wang H, Qiao X, Chen J, Wang X, Ding S (2005) Mechanisms of PVP in the preparation of silver nanoparticles. Mater Chem Phys 94:449–453

Zhang Z, Zhao B, Hu L (1996) PVP protective mechanism of ultrafine silver powder synthesized by chemical reduction processes. J Solid State Chem 121:105–110

Zhang W, Qiao X, Chen J, Wang H (2006) Preparation of silver nanoparticles in water-in-oil AOT reverse micelles. J Colloid Interface Sci 302:370–373

Zhao G, Steven SE (1998) Multiple parameters for the comprehensive evaluation of the susceptibility of Escherichia coli to the silver ion. Biometals 11:27–32

Zielinska A, Skwarek E, Zaleska A, Gazda M, Hupka J (2009) Preparation of silver nanoparticles with controlled particle size. Procedia Chemistry 1:1560–1566

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Natsuki, J., Natsuki, T. & Abe, T. Low molecular weight compounds as effective dispersing agents in the formation of colloidal silver nanoparticles. J Nanopart Res 15, 1483 (2013). https://doi.org/10.1007/s11051-013-1483-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-013-1483-y