Abstract

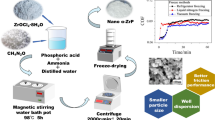

Spray freeze drying of yttria stabilised zirconia nanopowders with a primary particle size of ~16 nm has been undertaken using different solids content starting suspensions, with the effect of the latter on the flowability and crushability of the granules being investigated. The flowability and fill density of the granules increased with an increase in the solid content of the starting suspension, whilst the crushability decreased. The powder flowability, measured using a Hall flowmeter and model shoe-die filling tests, showed that the flowability of otherwise poorly flowable nanopowders can be improved to match that of the commercial spray dried submicron powder. The 5.5 vol.% solid content based suspension yielded soft agglomerates whilst a 28 vol.% solid content suspension formed hard agglomerates on spray freeze drying; the granule relics were visible in the fracture surface of the die pressed green compact in the latter case. The increase in granule strength is explained by the reduction in inter-particle distance based on the theories developed by Rumpf and Kendall. The flaw sizes computed using the Kendall model are comparable with those seen in the micrographs of the granule. With an optimum solid content, it is possible to have a granulated nanopowder with reasonable flowability and compactability resulting in homogeneous green bodies with ~54 % of theoretical density.

Similar content being viewed by others

References

Adi S, Adi H, Chan H, Finlay WH, Tong Z, Yang RYuA (2011) Agglomerate strength and dispersion of pharmaceutical powders. J Aerosol Sci 42:285–294

Amato I, Baudrocco F, Martorana D (1976) Evaluation of freeze drying and spray drying processes for preparing transparent alumina. Mater Sci Eng 26:73–78

Antonyuk S, Tomas J, Heinrich S, Mörl L (2005) Breakage behaviour of spherical granulates by compression. Chem Eng Sci 60:4031–4044

Barekar NS, Tzamtzis S, Hari Babu N, Fan Z, Dhindaw BK (2009) Processing of ultrafine-size particulate metal matrix composites by advanced shear technology. Metall Mater Trans A 40A:691–701

Barrett EP, Joyner LG, Halenda PP (1951) The determination of pore volume and area distributions in porous substances. I. Computations from nitrogen isotherms. J Am Chem Soc 73:373–380

Bertrand G, Roy P, Filiatre C, Coddet C (2005) Spray-dried ceramic powders: a quantitative correlation between slurry characteristics and shapes of the granules. Chem Eng Sci 60:95–102

Binner JGP, Annapoorani K, Santacruz I (2006) Patent No. WO 2006/136780 A2, 28 Dec 2006

Boulch F, Schouler MC, Donnadieu P, Chaix JM, Djurado E (2001) Domain size distribution of Y-TZP nano-particles using XRD and HRTEM. Image Anal Stereol 20:157–161

Cellard A, Zenati R, Garnier V, Fantozzi G, Baret G (2007) Optimization of chromium oxide nanopowders dispersion for spray-drying. J Eur Ceram Soc 27:1017–1021

Chen G, Wang W (2007) Role of freeze drying in nanotechnology. Dry Technol 25:29–35

Coury JR, Aguiar ML (1995) Rupture of dry agglomerates. Powder Technol 85:37–43

Ewais E, Zaman AA, Sigmund W (2002) Temperature induced forming of zirconia from aqueous slurries: mechanism and rheology. J Eur Ceram Soc 22:2805–2812

Fengqiu T, Xiaoxian H, Yufeng Z, Jingkun G (2000) Effect of dispersants on the surface chemical properties of nano-zirconia suspensions. Ceram Int 26:93–97

Garvie RC, Hannink RH, Pascoe RT (1975) Ceramic steel? Nature 258:703–704

Gregg SJ, Sing KSW (1982) Adsorption, surface area and porosity, 2nd edn. Academic Press, London, pp 173–194

Kendall K (1988) Agglomerate strength. Powder Metall 31:28–31

Kendall K, Weihs TP (1992) Adhesion of nanoparticles within spray-dried agglomerates. J Phys D 25:A3–A8

Li C, Akinc M (2005) Role of bound water on the viscosity of nanometric alumina suspensions. J Am Ceram Soc 88:1448–1454

Lukasiewicz SJ (1989) Spray-drying ceramic powders. J Am Ceram Soc 72:617–624

Mahdjoub H, Roy P, Filiatre C, Betrand C, Coddet G (2003) The effect of the slurry formulation upon the morphology of spray-dried yttria stabilised zirconia particles. J Eur Ceram Soc 23:1637–1648

Marinho B, Ghislandi M, Tkalya E, Koning CE, With G (2012) Electrical conductivity of compacts of graphene, multi-wall carbon nanotubes, carbon black, and graphite powder. Powder Technol 221:351–358

Moritz T, Nagy A (2002) Preparation of super soft granules from nanosized ceramic powders by spray freezing. J Nanoparticle Res 4:439–448

Moritz T, Nagy A (2004) Spray freeze granulates—from lab scale to pilot production presented at 7th international conference on nanostructured materials, Wiesbaden

Njiwa ABK, Aulbach E, Rodel J (2006) Mechanical properties of dry-pressed powder compacts: case study on alumina nanoparticles. J Am Ceram Soc 89:2641–2644

Park BD, Smith DM, Thoma SG (1993) Determination of agglomerate strength distributions, part 4. Analysis of multimodal particle size distributions. Powder Technol 76:125–133

Pyda W, Gani MSJ (1995) Microstructural and mechanical properties of spherical zirconia-yttria granules. J Mater Sci 30:2121–2129

Raghupathy BPC, Binner JGP (2011) Spray granulation of nanometric zirconia particles. J Am Ceram Soc 94:139–145

Rumpf H (1962) Strength of granules and agglomerates. In: Knepper WA (ed) Agglomeration. Wiley-Interscience, New York, pp 379–418

Santacruz MI, Annapoorani K, Binner JGP (2008) Preparation of high solids content nano zirconia suspensions. J Am Ceram Soc 91:398–405

Schneider LCR, Cocks ACF, Apostolopoulos A (2005) Comparison of filling behaviour of metallic, ceramic, hardmetal and magnetic powders. Powder Metall 48:77–84

Song J, Evans JRG (1994) A die pressing test for the estimation of agglomerate strength. J Am Ceram Soc 77:806–814

Tallón C, Moreno R, Nieto MI (2006) Synthesis of γ-Al2O3 nanopowders by freeze-drying. Mater Res Bull 41:1520–1529

Tan O (2004) Spray drying dielectric ceramics. Am Ceram Soc Bull 83:12–14

Tsetsekou A, Agrafiotis C, Leon A, Milias I (2001) Optimisation of the rheological properties of alumina slurries for ceramic processing applications, part II: spray drying. J Eur Ceram Soc 21:493–506

Uchida N, Hiranami T, Tanaka S, Uematsu K (2002) Spray freeze dried granules for ceramics fabrication. Am Ceram Soc Bull 81:57–60

Walker JS Jr, Reed WJ (1999) Influence of slurry parameters on the characteristics of spray dried granules. J Am Ceram Soc 82:1711–1719

Wu CY, Dihoru L, Cocks ACF (2003) The flow of powders into simple and stepped dies. Powder Technol 134:24–39

Acknowledgments

The authors would like to thank EPSRC/PowdermatriX for financial support, Prof. Alan Cocks, Oxford University, UK, and Dr. Farhad Motazedian, Leicester University, UK, for the model shoe-die filing experiments and Mr. Nikolaos Vlachos and Prof. Issac Chang, Birmingham University, UK, for use of their Hall flowmeter. Single granule strength tests were done by Ms. Susannah Eckhard and Ms. Jing (Sherry) Liu at the Fraunhofer Institut Keramische Technologien und Systeme in Dresden, Germany, and their time and access to the equipment is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supplementary material 1 (WMV 3951 kb)

Rights and permissions

About this article

Cite this article

Raghupathy, B.P.C., Binner, J.G.P. Spray freeze drying of YSZ nanopowder. J Nanopart Res 14, 921 (2012). https://doi.org/10.1007/s11051-012-0921-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-012-0921-6