Abstract

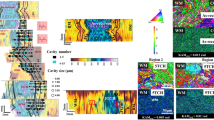

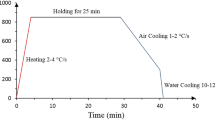

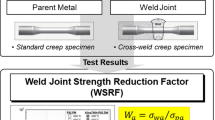

SA508 Gr.3 steel has been widely used in nuclear reactor pressure vessels (RPV). Nuclear components are generally combined through arc welding processes, which always produces heterogeneous mechanical properties in heat affected zone (HAZ) of weld joint. In order to study mechanical heterogeneity of weld joint, HAZ was been divided into five small regions (HAZ1 to HAZ5) based on the distance from the weld center line. The elastic modulus, hardness, and creep deformations of five regions in HAZ were measured through nanoindentation, as well as base and weld metals. According to the experimental results, the HAZ2 region (belonging to the fine-grained HAZ) exhibited a significantly lower hardness and creep behavior. Strain rate sensitivities (SRS) in different regions were then estimated from the steady-state creep, and the HAZ2 region showed a relatively higher value. The influence of grain boundary fraction on the creep behavior of weld joints was discussed later. Furthermore, the results of SRS also indicated that the creep mechanism of tested regions could be dominated by dislocation activities.

Similar content being viewed by others

References

Alkorta, J., Esnaola, J., Sevillano, J., et al.: Critical examination of strain-rate sensitivity measurement by nanoindentation methods: application to severely deformed niobium. Acta Mater. 56, 884–893 (2008)

Bower, A.F., Fleck, N.A., Needleman, A., et al.: Indentation of a power law creeping solid. Proc. R. Soc. Lond. (1993)

Cao, Z.H., Lu, H.M., Meng, X.K., et al.: Indentation size dependent plastic deformation of nanocrystalline and ultrafine grain Cu films at nanoscale. J. Appl. Phys. 105, 083521 (2009)

Chen, H., Song, Y.X., Zhang, T.H., et al.: Structure relaxation effect on hardness and shear transformation zone volume of a NiNb metallic glassy film. J. Non-Cryst. Solids 499, 257–263 (2018)

Choi, I., Yoo, B., Kim, Y., et al.: Indentation creep revisited. J. Mater. Res. 27(1), 3–11 (2012)

Choi, I.C., Kim, Y.J., Wang, Y.M., et al.: Nanoindentation behavior of nanotwinned Cu: influence of indenter angle on hardness, strain rate sensitivity and activation volume. Acta Mater. 61, 7313–7323 (2013)

Coble, R.L.: A model for boundary diffusion controlled creep in polycrystalline materials. J. Appl. Phys. 34, 1679 (1963)

Dimmler, G., Weinert, P., Cerjak, H.: Extrapolation of short-term creep rupture data—the potential risk of over-estimation. Int. J. Press. Vessels Piping 85, 55–62 (2008)

Elmustafa, A., Stoneb, D.: Nanoindentation and the indentation size effect: kinetics of deformation and strain gradient plasticity. J. Mech. Phys. Solids 51, 357–381 (2003)

Falat, L., Vyrostková, A., Homolová, V.: Creep deformation and failure of E911/E911 and P92/P92 similar weld-joints. Eng. Fail. Anal. 16, 2114–2120 (2009)

Fujiyama, K., Mori, K., Matsunaga, T., et al.: Creep-damage assessment of high chromium heat resistant steels and weldments. Mater. Sci. Eng. A 510–511, 195–201 (2009)

Guo, W., Dong, S., Guo, W., et al.: Microstructure and mechanical characteristics of a laser welded joint in SA508 nuclear pressure vessel steel. Mater. Sci. Eng. A 625, 65–80 (2015)

Hu, J., Zhang, W., Bi, G., et al.: Nanoindentation creep behavior of coarse-grained and ultrafine-grained pure magnesium and AZ31 alloy. Mater. Sci. Eng. A 698, 348–355 (2017)

Huang, P., Wang, F., Xua, M., et al.: Dependence of strain rate sensitivity upon deformed microstructures in nanocrystalline Cu. Acta Mater. 58(15), 5196–5205 (2010)

Jeyaganesh, B.: Overview of Welding Research Under the New Nuclear Manufacturing (NNUMAN) Programme (2014)

Johnson, K.L.: Contact Mechanics. Cambridge University Press, Cambridge (1987)

Laha, K., Chandravathi, K.S., Parameswaran, P., et al.: Type IV Cracking Susceptibility in Weld Joints of Different Grades of Cr-Mo Ferritic Steel, the Minerals. Metals & Materials Society and ASM International, New York (2008)

Li, X., Bhushan, B.: A review of nanoindentation continuous stiffness measurement technique and its applications. Mater. Charact. 48, 11–36 (2008)

Li, W.B., Henshall, J., Hooper, R., et al.: The mechanisms of indentation creep. Acta Metall. Mater. 39, 3099–3110 (1999)

Lu, H., Wang, B., Ma, J., Huang, G., et al.: Measurement of creep compliance of solid polymers by nanoindentation. Mech. Time-Depend. Mater. 7, 189–207 (2003)

Lu, C., He, Y., Yang, J.G., et al.: An investigation of phase transition on the microstructural characteristic and creep behavior for the SA508 Gr. 3 steel used for nuclear reactor pressure vessels. Mater. Sci. Eng. A 711, 659–669 (2018)

Ma, Y., Peng, G.J., Wen, D.H., et al.: Nanoindentation creep behavior in a CoCrFeCuNi high-entropy alloy film with two different structure states. Mater. Sci. Eng. A 621, 111–117 (2015a)

Ma, Y., Feng, Y.H., Debela, T.T., et al.: Nanoindentation study on the creep characteristics of high-entropy alloy films: FCC versus BCC structures. Int. J. Refract. Met. Hard Mater. 54, 395–400 (2015b)

Ma, Y., Peng, G.J., Feng, Y.H., et al.: Nanoindentation investigation on the creep mechanism in metallic glassy films. Mater. Sci. Eng. A 651, 548–555 (2016)

Ma, Y., Peng, G.J., Feng, Y.H., et al.: Nanoindentation investigation on creep behavior of amorphous CuZrAl/ nanocrystalline Cu nanolaminates. J. Non-Cryst. Solids 465, 8–16 (2017)

Ma, Y., Song, Y., Huang, X., et al.: Testing effects on shear transformation zone size of metallic glassy films under nanoindentation. Micromachines 9, 636 (2018a)

Ma, Y., Peng, G.J., Chen, H., et al.: On the nanoindentation hardness of Cu–Zr–Al/Cu nanolaminates. J. Non-Cryst. Solids 482, 208–212 (2018b)

Murty, K.L., Miraglia, P.Q., Mathew, M.D., et al.: Characterization of gradients in mechanical properties of SA-533B steel welds using ball indentation. Int. J. Press. Vessels Piping 76, 361–369 (1999)

Oliver, W., Pharr, G.M.: An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 7(6), 1564–1583 (1992)

Somekawa, H., Mukai, T.: Nanoindentation creep behavior of grain boundary in pure magnesium. Philos. Mag. Lett. 90(12), 883–890 (2010)

Su, C., Herbert, E.G., Sohn, S., et al.: Measurement of power-law creep parameters by instrumented indentation methods. J. Mech. Phys. Solids 61(2), 517–536 (2013)

Verón, P., Hippsley, C.A., Knott, J.F.: Comparative studies of stress-relief cracking in relaxation test specimens and in a full-scale weldment. Int. J. Press. Vessels Piping 16, 29–51 (1984)

Wang, F., Huang, P., Xu, K.W.: Time dependent plasticity at real nanoscale deformation. Appl. Phys. Lett. 90(16), 2715 (2007)

Wang, C.L., Lai, Y.H., Huang, J.C.: Creep of nanocrystalline nickel: a direct comparison between uniaxial and nanoindentation creep. Scr. Mater. 62, 175–178 (2010)

Watanabe, T., Masaaki, T., Masayoshi, Y., et al.: Creep damage evaluation of 9Cr–1Mo–V–Nb steel welded joints showing type IV fracture. Int. J. Press. Vessels Piping 83, 63–71 (2006)

Yang, J., Li, S.Y., Zhang, M.L., et al.: Welding process and welding consumable of generation III nuclear island main equipment. In: International Conference Pacific Basin Nuclear Conference. Springer, Singapore (2016)

Zhang, X.P., Dorn, L.: Investigation on the possibility of using the microshear test as a surveillance method to estimate the mechanical properties and fracture toughness of nuclear pressure vessel steel, A508CL3, and its joints welded by narrow-gap submerged-arc welding. Int. J. Press. Vessels Piping 76, 35–41 (1999)

Zhang, T.H., Ye, J.H., Feng, Y.H., et al.: On the spherical nanoindentation creep of metallic glassy thin films at room temperature. Mater. Sci. Eng. A 685, 294–299 (2017)

Zheng, W., He, Y., Yang, J., et al.: Hydrogen diffusion mechanism of the single-pass welded joint in welding considering the phase transformation effects. J. Manuf. Process. 36, 126–137 (2018)

Acknowledgements

The research work was supported by the National 13th five-year Key Technologies R&D Program (No. 2016YFC0801902), National Natural Science Foundation of China (51575489 and 11502235) and Zhejiang Provincial Natural Science Foundation of China (LY18E010006).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Song, Y., Huang, X., Gao, Z. et al. Nanoindentation creep behavior of RPV’s weld joint at room temperature. Mech Time-Depend Mater 24, 253–263 (2020). https://doi.org/10.1007/s11043-019-09419-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11043-019-09419-y