Abstract

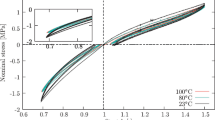

Observations are reported in uniaxial cyclic tensile tests with a strain-controlled program on perfluoroelastomer Hyflon MFA. A constitutive model is developed for its viscoplastic response and damage at three-dimensional deformations with finite strains. Adjustable parameters in the stress–strain relations are found by fitting the experimental data. Numerical simulation demonstrates that the constitutive equations adequately describe the mechanical response of perfluoroelastomer in cyclic tests with complicated deformation programs.

Similar content being viewed by others

References

Ameduri, B., Boutevin, B., Kostov, G.: Fluoroelastomers: synthesis, properties and applications. Progr. Polym. Sci. 26, 105–187 (2001)

Bergstrom, J.S., Kurtz, S.M., Rimnac, C.M., Edidin, A.A.: Constitutive modeling of ultra-high molecular weight polyethylene under large-deformation and cyclic loading conditions. Biomaterials 23, 2329–2343 (2002)

Bueche, F.: Mullins effect and rubber–filler interaction. J. Appl. Polym. Sci. 5, 271–281 (1961)

Chagnon, G., Verron, E., Gornet, L., Marckmann, G., Charrier, P.: On the relevance of continuum damage mechanics as applied to the Mullins effect in elastomers. J. Mech. Phys. Solids 52, 1627–1650 (2004)

Chagnon, G., Verron, E., Marckmann, G., Gornet, L.: Development of new constitutive equations for the Mullins effect in rubber using the network alteration theory. Int. J. Solids Struct. 43, 6817–6831 (2006)

Chen, J., Asano, M., Maekawa, Y., Yoshida, M.: Suitability of some fluoropolymers used as base films for preparation of polymer electrolyte fuel cell membranes. J. Membr. Sci. 277, 249–257 (2006)

De Tommasi, D., Puglisi, G., Saccomandi, G.: A micromechanics-based model for the Mullins effect. J. Rheol. 50, 495–512 (2006)

Diani, J., Brieu, M., Vacherand, J.M.: A damage directional constitutive model for Mullins effect with permanent set and induced anisotropy. Eur. J. Mech. A 25, 483–496 (2006)

Drozdov, A.D., Christiansen, J.deC.: Cyclic viscoplasticity of thermoplastic elastomers. Acta Mech. 194, 47–65 (2007)

Drozdov, A.D., Dorfmann, A.: Stress–strain relations in finite viscoelastoplasticity of rigid-rod networks: Applications to the Mullins effect. Continuum Mech. Thermodyn. 13, 183–205 (2001)

Erman, B., Flory, P.J.: Theory of elasticity of polymer networks. II. The effect of geometric constraints on junctions. J. Chem. Phys. 68, 5363–5369 (1978)

Erman, B., Monnerie, L.: Theory of elasticity of amorphous networks: effects of constraints along chains. Macromolecules 22, 3342–3348 (1989)

Goktepe, S., Miehe, C.: A micro-macro approach to rubber-like materials. III. The micro-sphere model of anisotropic Mullins-type damage. J. Mech. Phys. Solids 53, 2259–2283 (2005)

Govindjee, S., Simo, J.: Transition from micro-mechanics to computationally efficient phenomenology: Carbon black filled rubbers incorporating Mullins’ effect. J. Mech. Phys. Solids 40, 213–233 (1992)

Horgan, C.O., Ogden, R.W., Saccomandi, G.: A theory of stress softening of elastomers based on finite chain extensibility. Proc. R. Soc. A 460, 1737–1754 (2004)

Johnson, M.A., Beatty, M.F.: A constitutive equation for the Mullins effect in stress controlled uniaxial extension experiments. Continuum Mech. Thermodyn. 5, 301–318 (1993)

Kaliske, M., Nasdala, L., Rothert, H.: On damage modelling for elastic and viscoelastic materials at large strain. Comp. Struct. 79, 2133–2141 (2001)

Kafka, V., Vokoun, D.: On backstresses, overstresses, and internal stresses represented on the mesoscale. Int. J. Plast. 21, 1461–1480 (2005)

Kaushiva, B.D., Wilkes, G.L., Comeaux, C., Socha, L.: Structure-property relationships of poly(tetra fluoroethylene)–poly(tetrafluoroethylene-co-vinylidene fluoride-co-hexafluoropropylene) blends. Polymer 42, 4619–4633 (2001)

Likozar, B., Sebenik, U., Krajnc, M.: Modeling of dynamic mechanical properties of vulcanized fluoroelastomer. Polym. Eng. Sci. 47, 2085–2094 (2007)

Lin, R.C., Schomburg, U.: A finite elastic-viscoelastic-elastoplastic material law with damage: Theoretical and numerical aspects. Comp. Meth. Appl. Mech. Engng. 192, 1591–1627 (2003)

Losi, G.U., Knauss, W.G.: Free volume theory and nonlinear thermoviscoelastictity. Polym. Eng. Sci. 32, 542–557 (1992)

Mullins, L.: Softening of rubber by deformation. Rubber Chem. Technol. 42, 339–362 (1969)

Ogden, R.W., Roxburgh, D.G.: A pseudo-elastic model for the Mullins effect in filled rubber. Proc. R. Soc. A 455, 2861–2877 (1999)

Popelar, C.F., Liechti, K.M.: A distortion-modified free volume theory for nonlinear viscoelastic behavior. Mech. Time-Depend. Mater. 7, 89–141 (2003)

Simo, J.C.: On a fully three-dimensional finite-strain viscoelastic damage model: Formulation and computational aspects. Comp. Meth. Appl. Mech. Eng. 60, 153–173 (1987)

Souzy, R., Ameduri, B.: Functional fluoropolymers for fuel cell membranes. Progr. Polym. Sci. 30, 644–687 (2005)

Souzy, R., Ameduri, B., Boutevin, B., Gebel, G., Capron, P.: Functional fluoropolymers for fuel cell membranes. Solid State Ionics 176, 2839–2848 (2005)

Sullivan, R.W.: Development of a viscoelastic continuum damage model for cyclic loading. Mech. Time-Depend. Mater. 12, 329–342 (2008)

Tan, J., Chao, Y.J., Van Zee, J.W., Li, X., Wang, X., Yang, M.: Assessment of mechanical properties of fluoroelastomer and EPDM in a simulated PEM fuel cell environment by microindentation test. Mater. Sci. Eng. A 496, 464–470 (2008)

Turri, S., Levi, M., Cristini, M., Sanguineti, A.: Dynamic and thermo-mechanical properties of some specialty fluoroelastomers for low T g seal materials. J. Polym. Res. 14, 141–145 (2007)

Turri, S., Valsecchi, R., Levi, M., Cristini, M., Sanguineti, A.: Microstructure to property relations in a family of millable polyurethane fluoroelastomers. Eur. Polym. J. 44, 2951–2961 (2008)

Wang, S., Legare, J.M.: Perfluoroelastomer and fluoroelastomer seals for semiconductor wafer processing equipment. J. Fluorine Chem. 122, 113–119 (2003)

Xia, Z., Shen, X., Ellyin, F.: An assessment of nonlinearly viscoelastic constitutive models for cyclic loading: The effect of a general loading/unloading rule. Mech. Time-Depend. Mater. 9, 281–300 (2005)

Yakimets, I., Lai, D., Guigon, M.: Model to predict the viscoelastic response of a semi-crystalline polymer under complex cyclic mechanical loading and unloading conditions. Mech. Time-Depend. Mater. 11, 47–60 (2007)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Drozdov, A.D. Constitutive model for cyclic deformation of perfluoroelastomers. Mech Time-Depend Mater 13, 275–299 (2009). https://doi.org/10.1007/s11043-009-9085-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11043-009-9085-x