Abstract

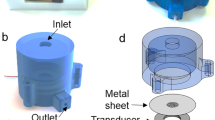

In this paper, a simple method was demonstrated to fabricate polydimethylsiloxane (PDMS) microfluidic chips used in rapid diagnosis based on printing the liquid molds directly. The liquid droplets were jetted by a glass micronozzle onto the hydrophilic glass substrate based on microfluidic pulse interior force to form various liquid molds, and then a replication process and a bonding process were followed for the fabrication of PDMS microfluidic chips. The effects of the wettability of the substrate and the overlap between the droplets on the formation of the liquid molds were investigated. Liquid molds with width ranging from 40 μm to 365 μm were prepared with an aspect ratio of 0.080 through controlling the overlap and the droplet size. The surface of the fabricated microchannels was smooth as the arithmetical mean deviation of the profile Ra was 179.1 nm with the 80 × 320 μm2 area at the bottom. The microreactions at the well-defined interfaces of several different solutions were realized with the fabricated PDMS microfluidic chips.

Similar content being viewed by others

Reference

Belligundu S, Shiakolas PS (2006) Study on two-stage hot embossing microreplication: silicon to polymer to polymer[J]. J Micro/Nanolithogr, MEMS MOEMS 5(2):021103–021103–8

Browne AW, Rust MJ, Jung WS, et al. (2009) A rapid prototyping method for polymer microfluidics with fixed aspect ratio and 3D tapered channels[J]. Lab Chip 9(20):2941–2946

Chang WH, Wang CH, Yang SY, et al. (2014) Rapid isolation and diagnosis of live bacteria from human joint fluids by using an integrated microfluidic system[J]. Lab Chip 14(17):3376–3384

Chung C, Chen YJ, Chen PC, et al. (2015) Fabrication of PDMS passive micromixer by lost-wax casting[J]. Int J Precis Eng Manuf 16(9):2033–2039

Easley CJ, Benninger RKP, Shaver JH, et al. (2009) Rapid and inexpensive fabrication of polymeric microfluidic devices via toner transfer masking[J]. Lab Chip 9(8):1119–1127

El-Dahshan ESA, Mohsen HM, Revett K, et al. (2014) Computer-aided diagnosis of human brain tumor through MRI: A survey and a new algorithm[J]. Expert Syst Appl 41(11):5526–5545

Eves DJ, Woolley AT (2009) Phase-changing sacrificial layers in microfluidic devices: adding another dimension to separations[J]. Anal Bioanal Chem 393(2):431–435

Fan Y, Liu Y, Li H, et al. (2012) Printed wax masks for 254 nm deep-UV pattering of PMMA-based microfluidics[J. J Micromech Microeng 22(2):027001

Jalalian A, Mashohor SBT, Mahmud HR, et al. (2013) Computer-aided detection/diagnosis of breast cancer in mammography and ultrasound: a review[J]. Clin Imaging 37(3):420–426

Jena RK, Yue CY, Lam YC, et al. (2012) Comparison of different molds (epoxy, polymer and silicon) for microfabrication by hot embossing technique[J]. Sensors Actuators B Chem 163(1):233–241

Kaigala GV, Ho S, Penterman R, et al. (2007) Rapid prototyping of microfluidic devices with a wax printer[J]. Lab Chip 7(3):384–387

Kenis PJA, Ismagilov RF, Whitesides GM (1999) Microfabrication inside capillaries using multiphase laminar flow patterning[J]. Science 285(5424):83–85

Koesdjojo MT, Tennico YH, Rundel JT, et al. (2008) Two-stage polymer embossing of co-planar microfluidic features for microfluidic devices[J]. Sensors Actuators B Chem 131(2):692–697

Lasave LC, Borisov SM, Ehgartner J, et al. (2015) Quick and simple integration of optical oxygen sensors into glass-based microfluidic devices[J]. RSC Adv 5(87):70808–70816

Liu X, Wang Q, Qin JH, et al. (2009) A facile “liquid-molding” method to fabricate PDMS microdevices with 3-dimensional channel topography[J]. Lab Chip 9(9):1200–1205

Looper J, Harrison M, Armato SGA (2016) Computer-aided diagnosis system to detect pathologies in temporal subtraction images of chest radiographs[C]//SPIE medical imaging. International Society for Optics and. Photonics:978539–978539

Lu Y, Lin B, Qin J (2011) Patterned paper as a low-cost, flexible substrate for rapid prototyping of PDMS microdevices via “liquid molding”[J]. Anal Chem 83(5):1830–1835

McDonald JC, Chabinyc ML, Metallo SJ, et al. (2002) Prototyping of microfluidic devices in poly (dimethylsiloxane) using solid-object printing[J]. Anal Chem 74(7):1537–1545

Mogensen KB, Kutter JP (2009) Optical detection in microfluidic systems[J. Electrophoresis 30(S1):S92–S100

Peng Y, Jiang Y, Yang C, et al. (2013) Quantitative analysis of multiparametric prostate MR images: differentiation between prostate cancer and normal tissue and correlation with Gleason score—a computer-aided diagnosis development study[J]. Radiology 267(3):787–796

Selvaraj H, Tan B, Venkatakrishnan K (2011) Maskless direct micro-structuring of PDMS by femtosecond laser localized rapid curing[J]. J Micromech Microeng 21(7):075018

Stoller MA, Konda A, Kottwitz MA, et al. (2015) Thermoplastic building blocks for the fabrication of microfluidic masters[J]. RSC Adv 5(119):97934–97943

Thomas MS, Clift JM, Millare B, et al. (2009) Print-and-peel fabricated passive micromixers[J]. Langmuir 26(4):2951–2957

Verma MKS, Majumder A, Ghatak A (2006) Embedded template-assisted fabrication of complex microchannels in PDMS and design of a microfluidic adhesive[J]. Langmuir 22(24):10291–10295

Ying L, Wang Q (2013) Microfluidic chip-based technologies: emerging platforms for cancer diagnosis[J]. BMC Biotechnol 13(1):76

Yu IF, Yu YH, Chen LY, et al. (2014) A portable microfluidic device for the rapid diagnosis of cancer metastatic potential which is programmable for temperature and CO 2[J]. Lab Chip 14(18):3621–3628

Yuan H, Liu Y, Jiang X, et al. (2014) Microfluidic chip for rapid analysis of cerebrospinal fluid infected with Staphylococcus Aureus[J]. Anal Methods 6(7):2015–2019

Yue W, Li CW, Xu T, et al. (2013) Screen printing of solder resist as master substrates for fabrication of multi-level microfluidic channels and flask-shaped microstructures for cell-based applications[J]. BIOSENSORS Bioelectronics 41:675–683

Zhang Y, Dong Z, Wu L, et al. (2011) A hybrid method for MRI brain image classification[J]. Expert Syst Appl 38(8):10049–10053

Zhang Y, Wang S, Ji G, et al. (2013) An MR brain images classifier system via particle swarm optimization and kernel support vector machine[J]. Sci World J 2013:130134

Zhang Y, Wang S, Ji G, et al. (2014) An improved quality guided phase unwrapping method and its applications to MRI[J. Prog Electromagn Res 145:273–286

Zhang Y, Wang S, Sun P, et al. (2015) Pathological brain detection based on wavelet entropy and Hu moment invariants[J]. Bio-Med Mater Eng 26(s1):S1283–S1290

Zhang YD, Wang SH, Liu G, et al. (2016) Computer-aided diagnosis of abnormal breasts in mammogram images by weighted-type fractional Fourier transform[J]. Advances in Mech Eng 8(2):1687814016634243

Zhu X, Zhu L, Chen H, et al. (2015) Fabrication of multi-scale micro-lens arrays on hydrophobic surfaces using a drop-on-demand droplet generator[J]. Opt Laser Technol 66:156–165

Acknowledgment

This work is supported by the National Natural Science Foundation of China (No.51175268) and the Open Program of Jiangsu Key Laboratory of 3D Printing Equipment and Manufacturing (No.BM2013006) and the Zhejiang Provincial Top Key Discipline of Mechanical Engineering.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yang, L., Zhu, L., Li, Z. et al. Fabrication of PDMS microfluidic chips used in rapid diagnosis by micro jetting. Multimed Tools Appl 77, 3761–3774 (2018). https://doi.org/10.1007/s11042-016-3958-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11042-016-3958-1