Behavior of promising aluminum-base composite materials reinforced with silicon carbide particles and discrete alumina fibers is analyzed under impact loading conditions. Workpieces for test specimens are prepared by liquid-phase combination of the components. Results of impact bending tests and analysis of fracture surfaces are used to determine the effect of fillers on material impact behavior and to evaluate the effect of reinforcement.

Similar content being viewed by others

References

Yu. A. Kurganova and A. G. Kolmakov, Structural Metal Matrix Composite Materials [in Russian], Izd. N. É. Bauman MGTU, Moscow (2015).

N. Chawla and K. K. Chawla, Metal Matrix Composites, Springer, New York (2013).

Yu. A. Kurganova, T. A. Chernyshova, L. I. Kobeleva, and S. V. Kurganov, “Service properties of aluminum-matrix precipitation- hardened composite materials and the prospects of their use on the modern structural material market,” Russian Metallurgy (Metally), No. 7, 663 – 666 (2011).

S. C. Tjong, “Recent progress in the development and properties of novel metal matrix nanocomposites reinforced with carbon nanotubes and graphene nanosheets,” Mater. Sci. Eng. R: Reports, No. 74, 281 – 350 (2013).

D. B. Miracle, “Metal matrix composites — from science to technological significance,” Compos. Sci. Technol., No. 65, 2526 – 2540 (2005).

A. D. Moghadam, E. Omrani, P. L. Menezes, and P. K. Rohatgi, “Mechanical and tribological properties of self-lubricating metal matrix nanocomposites reinforced by carbon nanotubes (CNTs) and graphene,” Composites. Part B. Engineering, No. 77, 402 – 420 (2015).

E. N. Kablov, “Strategic areas for development of materials and their preparation technology for the period up to 2030,” Aviats. Mater. Tekhnol., No. 5, 7 – 17 (2012).

G. A. Kosnikov, “Liquid phase production technologies of alumomatrix nanocomposite billets (review),” J. Sib. Fed. Univ., Eng. Technol., No. 7, 409 – 415 (2014).

K. U. Kainer, Metal Matrix Composites: Custom-Made Materials for Automotive and Aerospace Engineering, WILEY-VCH Verlag GmbH & Co, Weinheim (2006).

A. D. Romanov, E. A. Chernyshov, V. V. Myl’nikov, and E. A. Romanova, “Development fo technology for preparing composite material based on aluminum,” Mezhdunarod. Prikl. Fund. Issled., No. 12-2, 176 – 179 (2014).

J. Bae, K. Jung, S. Yoo, et al., “Design and fabrication of a metal-composite hybrid wheel with a friction damping layer for enhancement of ride comfort,” Composite Struct., No. 133, 576 – 584 (2015).

B. N. Sarada, M. P. L. Srinivasa, and G. Ugrasen, “Hardness and wear characteristics of hybrid aluminium metal matrix composites produced by stir casting technique,” Mater. Today: Proc., No. 2, 2878 – 2885 (2015).

H. Singh, N. J. Sarabjit, and A. K. Tyagi, “An overview of metal matrix composite: processing and SiC based mechanical properties,” J. Eng. Res. Studies, No. 2, 72 – 78 (2011).

A. J. Knowles, X. Jiang, M. Galano, and F. Audebert, “Microstructure and mechanical properties of 6061 Al alloy based composites with SiC nanoparticles,” J. Alloys Comp., No. 615, 401 – 405 (2014).

X. Yao, Y. F. Zheng, and J. M. Liang, “Microstructures and tensile mechanical properties of an ultrafine grained AA6063 – 5 vol% SiC metal matrix nanocomposite synthesized by powder metallurgy,” Mater. Sci. Eng. A, No. 648, 225 – 234 (2015).

P. B. Li, T. J. Chen, and H. Qin, “Effects of mold temperature on the microstructure and tensile properties of SiCp/2024 Al-based composites fabricated via powder thixoforming,” Mater. Design, No. 112, 34 – 45 (2016).

V. V. Berezovskii, Y. O. Solyaev, S. A. Lur’e, et al. “Mechanical properties of a metallic composite material based on an aluminum alloy reinforced by dispersed silicon carbide particles,” Russ. Metal. (Metally), No. 10, 790 – 794 (2015).

Y. A. Kurganova and S. P. Scherbakov, “Influence of a discrete additive of aluminum oxide on structure and properties of aluminum alloy,” Zapiski Gor. Inst., No. 228, 717 – 721 (2017).

Yu. A. Kurganova and I. Chen, “Preparation of cast metal matrix composite material specimens of the Al – Al2O3 – nano-fiber system,” Zagotovit. Proizvod. Mashin., No. 11, 524 – 528 (2018).

A. Mazahery, H. Abdizadeh, and H. R. Baharvandi, “Development of high-performance A356/nano-Al2O3 composites,” Mater. Sci. Eng. A, No. 518, 61 – 64 (2009).

I. El-Mahallawi, H. Abdelkader, L. Yousef, et al., “Influence of Al2O3 nano-dispersions on microstructure features and mechanical properties of cast and T6 heat-treated AlSi hypoeutectic alloys,” Mater. Sci. Eng. A, No. 556, 76 – 87 (2012).

Y. C. Kang and S. L. I. Chan, “Tensile properties of nanometric Al2O3 particulate-reinforced aluminum matrix composites,” Mater. Chem. Phys., No. 85, 438 – 443 (2004).

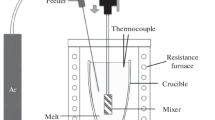

Yu. A. Lopatina, Yu. A. Kurganova, and V. K. Gaaze, “RF Patent 179266 MPK V 01 F 7/16. Device for mixing particles in molten metal matrix, Claimant and patent holder Yu. A. Lopatina, No. 2017130950,” Byull. Izobr. Polezn. Modeli, No. 13 (2018), claim 09.01.17, publ. 05.17.18.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 2, pp. 71 – 74, February, 2020.

Rights and permissions

About this article

Cite this article

Kurganova, Y.A., Shcherbakov, S.P., Chen, Y. et al. Evaluation of the Behavior of Promising Aluminum-Matrix Composite Materials Under Impact Loading Conditions. Met Sci Heat Treat 62, 174–178 (2020). https://doi.org/10.1007/s11041-020-00531-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-020-00531-2