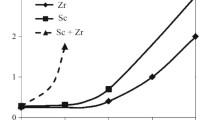

Two principles of alloying are suggested for creation of aluminum alloys sparingly alloyed with scandium, which intensify the metastability of the process of crystallization in continuous casting of ingots. The first principle consists in keeping a one-to-one scandium-to-zirconium proportion, for example, 0.11% Sc and 0.11% Zr. The second principle consists in multicomponent alloying with transition and rare-earth metals, which intensifies the metastability of crystallization.

Similar content being viewed by others

References

V. I. Elagin, V. V. Zakharov, S. G. Pavlenko, and T. D. Rostova, “Effect of zirconium addition on aging of Al – Sc alloys,” Fiz. Met. Metalloved., 60(1), 97 – 100 (1985).

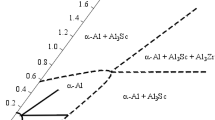

A. N. Kamardinkin, T. V. Dobatkina, and T. D. Rostova, “Isometric sections of the Al – Sc – Zr system at 500 and 600°C in the aluminum-rich range,” Metally, No. 2, 214 – 216 (1991).

V. I. Elagin, V. V. Zakharov and T. D. Rostova, “Aluminum alloys with scandium alloying,” Metalloved. Term. Obrab. Met., No. 1, 24 – 29 (1992).

V. Kh. Mann, “Ecoprocesses and the scandium project,” Redkie Zemli, No. 1, 98 – 103 (2017).

V. G. Davydov, V. I. Elagin, V. V. Zakharov, and T. D. Rostova, “About alloying of aluminum alloys with scandium and zirconium additions,” Metalloved. Term. Obrab. Met., No. 8, 25 – 30 (1996).

V. I. Dobatkina, “Laws of crystallization of ingots and granules,” Tekhnol. Legk. Splav., No. 3, 10 – 16 (1973).

V. I. Dobatkin, “About metastable equilibria in crystallization of alloys,” Izv. Akad. Nauk SSSR, Metally, No. 6, 27 – 32 (1082).

V. I. Dobatkin, “Joint action of supercooling of melt and external heat removal on formation of structure in ingots, castings and granules,” in: Aluminum and Engineering Progress [in Russian], VILS, Moscow (1987), pp. 164 – 171.

V. I. Dobatkin, V. I. Elagin, and V. M. Fedorov, Rapidly Crystallized Aluminum Alloys [in Russian], VILS, Moscow (1995), 340 p.

V. V. Zakharov and I. A. Fisenko, “On the problem of alloying of aluminum alloys with scandium,” Metalloved. Term. Obrab. Met., No. 5, 15 – 22 (2017).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 4, pp. 14 – 19, April, 2019.

Rights and permissions

About this article

Cite this article

Zakharov, V.V., Fisenko, I.A. Some Principles of Alloying of Aluminum Alloys with Scandium and Zirconium in Ingot Production of Deformed Semiproducts. Met Sci Heat Treat 61, 217–221 (2019). https://doi.org/10.1007/s11041-019-00403-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-019-00403-4