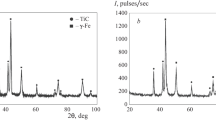

Special features of the structure of surface layers formed on billets of commercial-purity titanium VT1-0 by cladding a powder aluminum-titanium mixture with an electron beam removed into air atmosphere are studied. X-ray phase analysis and transmission electron microscopy are used to show that the material remelted by the electron beam is Ti3Al titanium aluminide. The hardness of the deposited layer is 540 – 610 HV. The behavior of the material is studied under the conditions of sliding friction and friction against fixed abrasive particles. The results reflect decrease in the friction factor and increase in the wear resistance of the clad material as compared to commercially pure titanium.

Similar content being viewed by others

References

M. Salehi and R. Hosseini, “Structural characterization of novel Ti-Cu intermetallic coatings,” Surf. Eng., 12, 221 – 224 (1996).

V. E. Oliker, S. N. Endrzheevskaya, V. D. Dobrovol’skii, et al., “Structure and properties of atomized coatings of intermetallic Fe – Ti and Ni – Ti powders,” Powder Metall. Met. Ceram., 32, 222 – 225 (1993).

M. N. Mokgalaka, S. L. Pityana, P. A. I. Popoola, et al., “NiTi intermetallic surface coatings by laser metal deposition for improving wear properties of Ti – 6Al – 4V substrates,” Adv. Mater. Sci. Eng., 2014, Art. 363917 (2014).

Y. Zhang, H. Li, and K. Zhang, “Investigation of the laser melting deposited TiAl intermetallic alloy on titanium alloy,” Adv. Mater. Res., 146 – 147, 1638 – 1641 (2011).

B. A. Grinberg and M. A. Ivanov, Ni 3 Al and TiAl Intermetallics: Microstructure and Deformation Behavior [in Russian], UrO RAN, Ekaterinburg (2002), 360 p.

G. Sauthoff, Intermetallics, Weinheim, VCH, New York, Basel, Cambridge, Tokyo (1995), 165 p.

K. S. Vecchio, “Synthetic multifunctional metallic-intermetallic laminate composites,” JOM, 57(3), 25 – 31 (2005).

A. V. Kartavykh, S. D. Kaloshkin, V. V. Cherdyntsev, et al., “Application of microstructured intermetallics in turbine manufacture. Pt. 1. Present state and prospects (a review),” Inorg. Mater., Appl. Res., 4(1), 12 – 20 (2013).

S. V. Chernobay, “Welding of alloys of titanium aluminides (a review),” Avtomat. Svarka, No. 8, 26 – 31 (2013).

A. F. Vaisman, M. G. Golkovskii, A. I. Korchagin, et al., “Technological applications of industrial electron accelerators of ELV series,” in: M. Markovits and J. Shiloh (eds.), BEAMS’98, Proc. 12th Int. Conf. on High-Power Particle Beams, Rafael, Israel; IEEE, New York (1998), Vol. 2, pp. 1039 – 1044.

I. Bataev, D. Mul, A. Bataev, et al., “Structure and tribological properties of steel after non-vacuum electron beam cladding of Ti, Mo and graphite powders,” Mater. Charact., 112, 60 – 67 (2016).

I. Bataev, M. Golkovskii, A. Bataev, et al., “Surface hardening of steels with carbon by non-vacuum electron-beam processing,” Surf. Coat. Technol., 242, 164 – 169 (2014).

D. O. Mul’, N. S. Belousova, D. S. Krivezhenko, et al., “Electron-beam deposition of titanium- and tantalum-containing powder mixtures on specimens of steel 40Kh,” Obrab. Met., Tekhnol., Obordud., Instr., No. 2(63), 117 – 126 (2014).

M. G Golkovskii, I. A. Bataev, A. A. Bataev, et al., “Atmospheric electron-beam surface alloying of titanium with tantalum,” Mater. Sci. Ang. A, Struct. Mater. Prop. Microstruct. Proc., 578, 310 – 317 (2013).

O. Lenivtseva, I. Bataev, M. Golkovskii, et al., “Structure and properties of titanium surface layers after electron beam alloying with powder mixtures containing carbon,” Appl. Surf. Sci., 355, 320 – 326 (2015).

S. A. Saltykov, Stereometric Metallography [in Russian], Metallurgiya, Moscow (1970), 376 p.

J. C. Rawers and D. E. Alman, “Fracture characteristics of metal/intermetallic laminar composites produced by reaction sintering and hot pressing,” Comp. Sci. Technol., 54(4), 379 – 384 (1995).

Yu. P. Trykov, V. N. Arisova, S. A. Volobuev, et al., “Examination of the fine structure of the weld zone of explosion-welded titanium-steel joints,” Weld. Int., 13(1), 64 – 66 (1999).

Yu. P. Trykov, “Complex technological processes of production of composite materials and articles,” Nauka Proizvod., No. 1, 20 – 23 (2000).

Yu. P. Trykov and V. G. Shmorgun, Properties and Operating Capacity of Laminar Composites [in Russian], Politekhnik, Volgograd (1999), 189 p.

J. Kajuch, J. Short, and J. J. Lewandowski, “Deformation and fracture behavior of Nb in Nb5Si3 /Nb laminates and its effect of laminate toughness,” Acta Meall. Mater., 43(5), 1955 – 1967 (1995).

I. A. Bataev, A. A. Bataev, V. I. Mali, et al., “Nucleation and growth of titanium aluminide in explosion-welded laminar composite,” Fiz. Met. Metalloved., 113(10), 998 – 1007 (2012).

D. Lazurenko, I. Bataev, V. Mali, et al., “Explosively welded multilayer Ti – Al composites: structure, and transformation during heat treatment,” Mater. Design, 102, 122 – 130 (2016).

Jean-Marie Dubois, “An introduction to complex metallic alloys and to the CMAnetwork of excellence,” in: Basics of Thermodynamics and Phase Transitions in Complex Intermetallics, World Scientific Publishing, Singapore (2008), pp. 1 – 31.

G. V. Samsonov and I. M. Vinnitskii, Refractory Compounds [in Russian], Metallurgiya, Moscow (1976).

V. R. Ryabov, Welding of Aluminum and Its Alloys with Other Metals [in Russian], Naukova Dumka, Kiev (1983), 264 p.

Ge. E. Totten and D. Scott MacKenzie (eds.), Handbook of Aluminum. Vol. 2. Alloy Production and Materials Manufacturing, Marcel Dekker Inc., New York, Basel (2003), 724 p.

The work has been performed with financial assistance of the Russian Foundation for Basic Research within Scientific Project No. 15-38-20776mol a ved.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 10, pp. 4 – 10, October, 2018.

Rights and permissions

About this article

Cite this article

Bataev, I.A., Lazurenko, D.V., Golkovskii, M.G. et al. Surface Hardening of Titanium Under Non-Vacuum Electron-Beam Cladding of an Aluminum-Containing Powder Mixture. Met Sci Heat Treat 60, 619–624 (2019). https://doi.org/10.1007/s11041-019-00328-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-019-00328-y