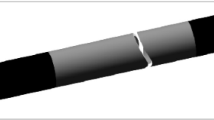

The crack resistance of welded joints of pipe steels of strength class K60 and different alloying systems is studied. The parameter of the crack tip opening displacement (CTOD) is shown to be dependent on the size of the austenite grains and on the morphology of bainite in the superheated region of the heat-affected zone of the weld. The crack resistance is shown to be controllable due to optimization of the alloying system.

Similar content being viewed by others

Notes

The study was performed at the collective-use “Test Center for Nanotechnologies and Promising Materials” of the Institute of Metal Physics of the Ural Branch the Russian Academy of Sciences.

References

L. I. Efron, Metal Science in “Large” Metallurgy. Pipe Steels [in Russian], Metallurgizdat, Moscow (2012), 696 p.

V. M. Schastlivtsev, I. L. Yakovleva, N. A. Tereshchenko, et al., “Main structural factors of hardening of low-carbon low-alloy pipe steels after controlled rolling,” Metalloved. Term. Obrab. Met., No. 1, 41 – 45 (2009).

E. S. Gorkunov, S. M. Zadvorkin, E. A. Putilova, and R. A. Savray, “Effect of the structure and stress state on the magnetic properties of metal in different zones of welded large-diameter pipes,” Fiz. Met. Metalloved., 115(10), 1011 – 1019 (2014).

A. B. Arabey, “Development of technical requirements on the metal of pipes of cross-country pipelines,” Izv. Vysh. Uchebn. Zaved., Chern. Metall., No. 7, 3 – 10 (2010).

A. A. Ostsemin and V. L. Dilman, “Crack resistance and impact toughness of longitudinally and spiral-welded pipes,” Stal’, No. 10, 44 – 49 (2001).

M. A. Shtremel, Fracture, Book 1 [in Russian], Izd. Dom MISiS (2014), 670 p.

A. B. Arabey, I. I. Frantov, V. I. Stolyarov, and I. L. Permyakov, “Weldability and quality assurance of welded joints in the production of high-strength gas-line pipes,” Nauka Tekh. Gaz. Prom., No. 4, 4 – 19 (2009).

L. A. Efimenko and A. A. Ramus’, “Effect of the structure morphology on the resistance of welded joints of high-strength pipe steels to brittle fracture,” Metalloved. Term. Obrab. Met., No. 6, 34 – 38 (2015).

V. A. Khotinov, V. M. Farber, A. N. Morozova, et al., “Structure and mechanical properties of technological welded joints of gas-line pipes,” Metalloved. Term. Obrab. Met., No. 9, 41 – 45 (2014).

M. L. Bernshtein and A. G. Rakhshtadt (eds.), Metal Science and Heat Treatment, Vol. 2, Fundamentals of Heat Treatment [in Russian], Metallurgiya, Moscow (1983), 386 p.

The work has been performed within State specification on the topic “Structure” (No. 01201463331) with support of Project No. 15-15-2-16 of the Ural Branch of the Russian Academy of Sciences.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 12, pp. 24 – 30, December, 2017.

Rights and permissions

About this article

Cite this article

Tabatchikova, T.I., Tereshchenko, N.A., Yakovleva, I.L. et al. Crack Resistance of Welded Joints of Pipe Steels of Strength Class K60 of Different Alloying Systems. Met Sci Heat Treat 59, 767–772 (2018). https://doi.org/10.1007/s11041-018-0224-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-018-0224-3