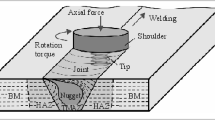

Welded joints of aluminum alloy 6082-T6 formed by the method of impulse friction stir welding are studied. The effect of the power and frequency of the pulses on the microstructure and mechanical properties of the welded joints is determined. Application of an additional pulse during the welding affects the surface quality and the shape of the weld, the distribution of the oxide layer and of particles of the hardening phase, and the grain size in the zone of dynamic recrystallization.

Similar content being viewed by others

References

V. Michailov, Impuls-Rührreibschweißen (Impulse Friction Stir Welding), DE 199 53 260.5.

W. M. Thomas, E. D. Nicholas, J. C. Needham, et al., International Patent Application No. PCT_GB92_02203, GB Patent Application No. 9125978.8 (1991).

S. Yu. Kondrat’ev and O. V. Shvetsov, “Effect of high-temperature heating on the structure and properties of aluminum alloys in the production of drill pipes,” Metal Sci. Heat Treat., 55(3 – 4), 191 – 196 (2013).

S. Yu. Kondrat’ev, O. G. Zotov, and O. V. Shvetsov, “Structural stability and variation of properties of aluminum alloys D16 and 1953 in the production and operation of drill pipes,” Metal Sci. Heat Treat., 55(9 – 10), 526 – 532 (2014).

V. Michailov, C. Hantelmann, and A. Kloshek, “Impulsrührreibschweißen—Ein Verfahren mit neuen Möglichkeiten,” in: Große Schweißtechnische Tagung, DVS Band 275 (2011), pp. 171 – 176.

R. S. Mishra and Z. Y. Ma, “Friction stir welding and processing,” Mater. Sci. Eng. R: Reports, 50(1 – 2), 1 – 78 (2005).

P. Niu, W. Li, Z. Zhang, et al., “Significant effect of oxide on mechanical properties of friction-stir welded AA2024 joints,” Sci. Technol. Weld. Join., 22, 66 – 70 (2016).

Y. S. Sato, F. Yamashita, Y. Sugiura, et al., “FIB-assisted TEM study of an oxide array in the root of a friction stir welded aluminum alloy,” Scr. Mater., 50, 365 – 369 (2004).

C. Zhou, X. Yang, and G. Luan, “Effect of oxide array on the fatigue property of friction stir welds,” Scr. Mater., 54, 1515 – 1520 (2006).

T. Le. Jolu, T. F. Morgeneyer, and A. F. Gourgues-Lorenzon, “Effect of joint line remnant on fatigue lifetime of friction stir welded Al – Cu – Li alloy,” Sci. Technol. Weld. Join., 15, 694 – 698 (2010).

Y. S. Sato, H. Takauchi, S. H. C. Park, and H. Kokawa, “Characteristics of the kissing-bond in friction stir welded Al alloy 1050,” Mater. Sci. Eng. A, 405, 333 – 338 (2005).

H. J. Liu, H. J. Liu, Y. C. Chen, and J. C. Feng, “Effect of zigzag line on the mechanical properties of friction stir welded joints of an Al – Cu alloy,” Scr. Mater., 55, 231 – 234 (2006).

L.-E. Svensson, L. Karlsson, H. Larsson, et al., “Microstructure and mechanical properties of friction stir welded aluminum alloys with special reference to AA5083 and AA6082,” Sci. Technol. Weld. Join., 5, 285 – 296 (2000).

L. Karlsson, L.-E. Svensson, and H. Larsson, in: Proc. 5th Int. Conf. on Trends inWelding Research, Pine Mountain, GA, USA, June 1 – 5, ASM Int. (1998), pp. 574 – 579.

W. F. Mao and D. E. Laughlin, “Effects of Cu content and preaging on precipitation characteristics in aluminum alloy 6062,” Metall. Mater. Trans. A, 31A, 361 – 371 (2000).

Y. S. Sato, H. Kokawa, M. Enomoto, and S. Jogan, “Microstructural evolution of 6063 aluminum during friction-stir welding,” Metall. Mater. Trans. A, 30A, 2429 – 2437 (1999).

C. A. W. Olea, L. Roldo, J. F. dos Santos, and T. R. A. Strohaecker, “A sub-structural analysis of friction stir welded joints in an AA6056 Al-alloy in T4 and T6 temper conditions,” 454 – 455, 52 – 62 (2007).

C. A. Weis Olea, Influence of Energy Input in Friction Stir Welding on Structure Evolution and Mechanical Behavior of Precipitation-Hardening in Aluminum Alloys (AA2024-T351, AA6013-T6 and Al – Mg – Sc) (2008).

Kh. A. A. Hassan, P. B. Prangnell, A. Norman, et al., “Effect of welding parameters on nugget zone microstructure and properties in high strength aluminum alloy friction stir welds,” Sci. Technol. Weld. Join., 8, 257 – 268 (2003).

W. B. Lee, Y. M. Yeon, and S. B. Jung, “Evaluation of the microstructure and mechanical properties of friction stir welded 6005 aluminum alloy,” Mater. Sci. Technol., 19, 513 – 518 (2003).

C. Genevois, A. Deschamps, A. Denquin, and B. Doisneaucottignies, “Quantitative investigation of precipitation and mechanical behavior for AA2024 friction stir welds,” Acta Mater., 53, 2447 – 2458 (2005).

P. L. Threagill. A. J. Leonard, H. R. Shercliff, and P. J. Withers, “Friction stir welding of aluminum alloys,” Int. Mater. Rev., 54(2), 49 – 93 (2009).

The work has been performed at the Peter the Great St. Petersburg Polytechnic University within Agreement No. 14.Z50.31.0018 with the Ministry of Education and Science of the Russian Federation.

The authors are sincerely grateful to Sebastian Boltz (Department of Metal Science and Technology of Materials of the Brandenburg University of Technology) for the assistance in the scanning electron microscope studies.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 11, pp. 25 – 30, November, 2017.

Rights and permissions

About this article

Cite this article

Kondrat’ev, S.Y., Morozova, Y.N., Golubev, Y.A. et al. Microstructure and Mechanical Properties of Welds of Al – Mg – Si Alloys After Different Modes of Impulse Friction Stir Welding. Met Sci Heat Treat 59, 697–702 (2018). https://doi.org/10.1007/s11041-018-0213-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-018-0213-6