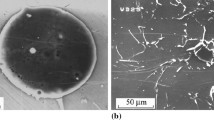

The microstructure of coatings deposited under radiation heating in vacuum at different parameters of pulsed glow discharge is studied. It is shown that depending on the length of the pulses of the glow discharge the deposited coatings may have alternating different-thickness chromium carbide layers.

Similar content being viewed by others

References

V. E. Ivanov, E. P. Nechiporenko, V. M. Krivoruchko, and V. V. Sagalovich, Crystallization of Refractory Metals from Gas Phase [in Russian], Atomizdat, Moscow (1974), 264 p.

V. I. Yurshev, R. I. Mukatdarov, and I. V. Yurshev, “Surface hardening of tools by depositing a pyrolytic chromium carbide coating,” Metalloved. Term. Obrab. Met., No. 2, 48 – 52 (2015).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 10, pp. 32 – 35, October, 2017.

Rights and permissions

About this article

Cite this article

Yurshev, V.I., Serdyuk, A.I., Mukatdarov, R.I. et al. Deposition of Coatings Under Pulsed Action of Glow Discharge. Met Sci Heat Treat 59, 637–640 (2018). https://doi.org/10.1007/s11041-018-0203-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-018-0203-8