The effect of nanostructuring on the strength and fracture mechanism of materials possessing different crystal lattices is analyzed on the basis of available reports and experimental data of the authors. The structure, the hardness, the crack resistance, and the strength and ductility characteristics of steel 10 (bcc lattice), aluminum alloy AK4-1 (fcc lattice), austenitic steel AISI 321 (fcc lattice) are studied after equal channel angular pressing (ECAP) and those of Grade 4 titanium (hcp lattice) are studied after a ECAP-conform process (ECAP-C). It is shown that the ultrafine-grained (UFG) structure produced by the ECAP affects ambiguously the static crack resistance of the materials studied. The type of the crystal lattice influences substantially the temperature behavior of the impact toughness of the studied materials with UFG structure.

Similar content being viewed by others

References

R. Z. Valiev and I. V. Aleksandrov, Bulk Nanostructured Metallic Materials: Fabrication, Structure and Properties [in Russian], IKTs “Akademkniga,” Moscow (2007), 398 p.

Ruslan Z. Valiev, Alexander P. Zhilyaev, and Terence G. Langdon, Bulk Nanostructure Materials: Fundamentals and Applications, TMS, WILEY (2014), 440 p.

R. Z. Valiev, “Creation of nanostructured metals and alloys with unique properties using severe plastic deformations,” Ross. Nanotekhnol., 1(1 – 2), 208 – 216 (2006).

V. S. Zolotorevskii, Mechanical Properties of Metals [in Russian], MISiS, Moscow (1998), 400 p.

N. Tsuji, R. Ueji, Y. Minamino, and Y. Saito, “A new and simple process to obtain nano-structured bulk low-carbon steel with superior mechanical property,” Scr. Mater., 46, 305 – 310 (2002).

A. Honenwarter and R. Pippan, “Fracture toughness and fatigue crack propagation measurements in ultrafine grained iron and nickel,” TMS, USA, 183 – 188 (2008).

R. Song, D. Ponge, D. Raabe, et al., “Overview of processing, microstructure and mechanical properties of ultrafine grained bcc steels,” Mater. Eng., A441, 1 – 7 (2006).

L. R. Botvina, M. I. Alymov, M. R. Tyutin, et al., “Fracture kinetics of nickel with inhomogeneous nanostructure,” Ross. Nanotekhnol., 2(1 – 2), 106 – 111 (2007).

I. Sabirov, R. Z. Valiev, I. P. Semenova, and R. Pippan, “Effect of equal channel angular pressing on the fracture behavior of commercially pure titanium,” Metall. Mater. Trans., 41A, March, 727 – 733 (2010).

A. Honenwarter and R. Pippan, “Fracture of ECAP-deformed iron and the role of extrinsic toughening mechanisms,” Acta Mater., 61, 2973 – 2983 (2013).

F. Wetscher, R. Stock, and R. Pippan, “Fracture processes in severe plastic deformed rail steels,” in: Proc. 16th European Conf. on Fracture, Alexandropoulos, Greece (2006), pp. 1 – 9.

L. S. Moroz, The Mechanics and Physics of Deformations and Fracture of Materials [in Russian], Mashonostroenie, Leningrad (1984), 224 p.

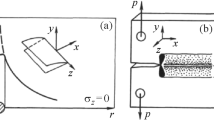

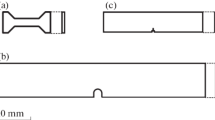

GOST 25.506–85. Design and Testing for Strength. Methods of Mechanical Tests of Metals. Determination of Characteristics of Crack Resistance (Fracture Toughness) under Static Loading [in Russian], Izd. Standartov, Moscow (1985), 62 p.

G. V. Klevtsov, L. P. Botvina, N. A. Klevtsova, and L. V. Limar’, Fractodiagnostics of Facture of Metallic Materials and Structures [in Russian], MISiS, Moscow (2007), 264 p.

R. A. Andrievskii and A. M. Glezer, “Strength of nanostructures,” Usp. Fiz. Nauk, 179(4), 337 – 358 (2009).

L. P. Botvina, The Kinetics of Fracture of Structural Materials [in Russian], Nauka, Moscow (1989), 1989 p.

R. Z. Valiev, N. A. Klevtsova, G. V. Klevtsov, et al., “Mechanism of fracture and martensitic transformations in plastic zones of austenitic steel AISI 321 after equal channel angular pressing,” Deform. Razrush. Mater., No. 10, 14 – 18 (2010).

R 50-54-52/2–94. Design and Testing for Strength. Method of x-ray Diffraction Analysis of Fractures. Determination of Characteristics of Fracture of Metallic Materials by X-Ray Technique [in Russian], VNIINMASh Gosstandarta Rossii, Moscow (1994), 28 p.

G. V. Klevtsov, L. R. Botvina, and N. A. Klevtsova, “X-ray diffraction technique for analysing failed components,” ISIJ Int., 36(2), 222 – 228 (1996).

R 50-54-52–88. Design and Testing for Strength. Method of X-Ray Diffraction Analysis of Fractures, Determination of the Depth of Zones of Plastic Deformation under Fracture Surfaces [in Russian], VNIINMASh Gosstandarta SSSR, Moscow (1988), 24 p.

G. V. Klevtsov, R. Z. Valiev, G. I. Raab, et al., “Mechanism of impact fracture of steel 10 with submicrocrystalline structure in the range of ductile-brittle transition,” Deform. Razrush. Mater., No. 8, 9 – 13 (2011).

R. Z. Valiev, G. V. Klevtsov, I. P. Semenova, et al., “Strength and mechanism of impact fracture of Grade 4 titanium and titanium alloy VT6 in original and submicrocrystalline states,” Deform. Razrush. Mater., No. 11, 32 – 37 (2012).

G. V. Klevtsov, R. Z. Valiev, R. K. Islamgaliev, et al., “Effect of nanostructuring on static crack resistance of aluminum alloy,” Deform. Razrush. Mater., No. 11, 8 – 12 (2014).

R. K. Islamgaliev, K. M. Nesterov, E. D. Khafizova, et al., “Strength and fatigue of ultrafine grained aluminum alloy AK4-1,” Vest. UGATU, 16[8(53)], 104 – 109 (2012).

N. A. Klevtsova, O. A. Frolova, and G. V. Klevtsov, Fracture of Austenitic Steels and Martensitic Transformations in Plastic Zones [in Russian], Izd. Akad. Estestvoznan., Moscow (2005), 155 p.

G. V. Klevtsov, R. Z. Valiev, R. K. Islamgaliev, et al., “Strength and fracture mechanism of aluminum alloy AK4-1 in submicrocrystalline condition under static and impact loading,” Fundam. Issled., No. 8(2), 281 – 285 (2013).

The work has been performed with financial support of Grant 14-08-00301 of the Russian Foundation for Basic Research and partial financial support of the Ministry of Education and Science of the Russian Federation (Resolution 220, Grant of the RF Government, Agreement No. 14.V25.31.0017).

The authors are obliged to R. K. Islamgaliev, I. P. Semenova, G. I. Raab, E. D. Merson, and I. N. Pigaleva for the materials supplied and for the help with the tests.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 9, pp. 54 – 62, September, 2017.

Rights and permissions

About this article

Cite this article

Klevtsov, G.V., Valiev, R.Z., Klevtsova, N.A. et al. Strength and Fracture Mechanisms of Nanostructured Metallic Materials Under Single Kinds of Loading. Met Sci Heat Treat 59, 597–605 (2018). https://doi.org/10.1007/s11041-018-0197-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-018-0197-2