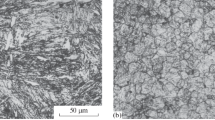

The structure and properties of nitrided sparingly alloyed low-carbon steels of martensitic class with different contents of vanadium are studied. Nitriding of low-carbon steels with a high vanadium content is shown to produce a favorable effect on the hardness and thickness of their surface layer.

Similar content being viewed by others

References

Yu. M. Lakhtin, Ya. D. Kogan, H.-J. Spies, and Z. Bömer, The Theory and Technology of Nitriding [in Russian], Metallurgiya, Moscow (1991), 320 p.

S. A. Gerasimov, Advanced Methods of Nitriding [in Russian], Mashinostroenie, Moscow (1985), 32 p.

O. V. Silina, L. M. Kleiner, N. N. Mitrokhovich, and N. V. Cheremnykh, “Raising the heat resistance of nitrided low-carbon martensitic steels,” Metalloved. Term. Obrab. Met., No. 1, 17–20 (1998).

S. S. Yugay, L. M. Kleiner, and A. A. Shatsov, “Structure and properties of nitrided low-carbon martensitic steel 12Kh2G2NMFT,” Fiz. Met. Metalloved., 99(1), 110–115 (2005).

L. M. Kleiner and A. A. Shatsov, Novel Structural Materials: Low-Carbon Martensitic and Powder Steels. Applied Metals Science: A Study Aid [in Russian], PGTU, Perm (2004), 142 p.

L. N. Mirkin, X-Ray Diffraction Control of Machine-Building Materials, A Handbook [in Russian], Metallurgiya, Moscow (1970), 366 p.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 11, pp. 50 – 54, November, 2012.

Rights and permissions

About this article

Cite this article

Yugay, S.S., Silina, O.V. & Trutneva, T.S. Nitriding of sparingly alloyed low-carbon steels of martensitic class. Met Sci Heat Treat 54, 605–608 (2013). https://doi.org/10.1007/s11041-013-9557-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11041-013-9557-0