Abstract

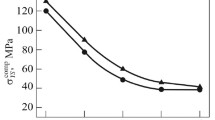

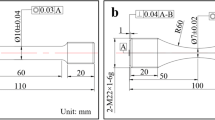

Mechanical properties under static and dynamic loads, fatigue characteristics, fracture toughness, high-temperature strength, corrosion resistance, and physical and thermophysical properties of pressed alloy V-1469 in state T1 are studied. The alloy belongs to the group of aluminum high-strength deformable heat-hardenable alloys based on the Al-Cu-Li-Mg system with additives of Ag, Zr, and Sc. The properties of pressed strips from alloys V-1469T1, V95ochT2, and V96ts3-T12 are compared.

Similar content being viewed by others

References

I. N. Fridlyander, V. F. Shamrai, and N. V. Shiryaeva, “A study of heat hardening of AlLiMg alloys,” Izv. Akad. Nauk SSSR, No. 2 (1965).

I. N. Fridlyander, V. F. Shamrai, and N. V. Shiryaeva, Diploma for Invention 390, Phenomenon of Growth in the Strength and Stiffness of Aluminum-Magnesium-Lithium System with Simultaneous Decrease in the Density (Fridlyander Effect) [in Russian], Moscow (1964).

J. Aircraft, 37(1), 24–25 (2000).

I. N. Fridlyander, in: Aircraft Materials, Issue “Promising Aluminum, Magnesium, and Titanium Alloys for Aerospace Engineering” [in Russian], VIAM, Moscow (2002), pp. 3–11.

E. A. Starke, in: J. NASA-UVA Light Aerospace Alloy and Structures Technology Program Supplement: Aluminum-Based Materials for High Speed Aircraft, NASA CR-97-206248 (1997), pp. 3–51.

I. N. Fridlyander, Recollections. About Creation of Aerospace and Nuclear Engineering Equipment from Aluminum Alloys [in Russian], Nauka, Moscow (2005).

Aviation Week & Space Technol., June 17 (1996).

“The aerospace vehicle “Space Shuttle” fuel tank,” Modern Met. II, 56(1), 10, 12–16 (2000).

Progr. Aerospace Sci., 32, 131–172 (1996).

“Airbus confident on A350 orders,” Flight Int., 21 Dec.–3 Jan., 13 (2005).

I. N. Fridlyander, E. N. Kablov, O. E. Glushko, et al., “Aluminum-based alloy and an article fabricated from it, RF Patent No. 2237098,” Byul. Izobr. Polezn. Modeli, No. 27 (2004).

Yu. M. Vainblat, “Continuous recrystallization in hot-deformed aluminum alloys,” Tekhnol. Legk. Splavov, No. 3, 11–19 (1992).

V. F. Shamrai, O. E. Grushko, I. V. Égis, and S. N. Borovskikh, “Crystallographic texture and structure of rolled sheets from an alloy of the Al-Cu-Li system,” Metally, RAN, No. 2, 94–98 (2006).

Author information

Authors and Affiliations

Additional information

__________

Translated from Metallovedenie i Termicheskaya Obrabotka Metallov, No. 6, pp. 3–7, June, 2007.

Rights and permissions

About this article

Cite this article

Fridlyander, I.N., Grushko, O.E., Shamrai, V.F. et al. High-strength structural silver-alloyed underdensity Al-Cu-Li-Mg alloy. Met Sci Heat Treat 49, 279–283 (2007). https://doi.org/10.1007/s11041-007-0049-y

Issue Date:

DOI: https://doi.org/10.1007/s11041-007-0049-y