Abstract

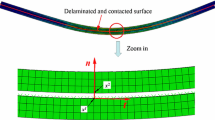

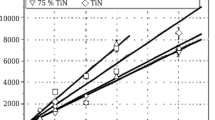

The adaptive mode of frictional interaction has been studied as a self-locking effect upon contact deformation of isotropic and anisotropic auxetic materials with a negative Poisson ratio. This effect manifests itself in the fact that the bearing capacity of the joint rises with increasing shear load. In particular, the parameters of stress state (contact load, tangential stresses, slippage, etc.) were determined for a double-lap joint under conditions of compression with or with out shear. The contact interaction was analyzed by the finite-element method for three profiles of symmetrically located contact elements (plane, cylindrical, and wedge-shaped). The Poisson ratio was varied within the range theoretically admissible for isotropic elastic media. Analogous calculations were also performed for a joint with a deformed element made of an anisotropic auxetic composite, whose reinforcement angle was varied. The maximum loads, tangential stresses, and slippage are obtained as nonlinear functions of Poisson ratio (in the isotropic case) and reinforcement angle of the composite material. The stress concentration and the increased ultimate shear forces are also estimated.

Similar content being viewed by others

References

D. A. Konek, K. Voitsekhovskii, Yu. M. Pleskachevskii, and S. V. Shilko, “Materials with a negative Poisson ratio (a review),” Mekh. Kompozit. Mater. Konstr., 10, No. 1, 35–69 (2004).

A. E. H. Love, A Treatise on the Mathematical Theory of Elasticity, 4th Ed., Dover, New York (1944).

Yu. M. Pleskachevskii, S. V. Shil’ko, and S. V. Stel’makh, “Stages of development and levels of organization of the structure of materials: adaptive composites,” Dokl. Belar. Nats. Akad. Nauk, 43, No. 5, 119–123 (1999).

S. V. Shilko, S. V. Stelmakh, D. A. Chernous, and Yu. M. Pleskatchevskii, “Structural simulation of supercompressible materials,” J. Theor. Appl. Mech., 28, No. 1, 87–96 (1998).

S. V. Shilko and Yu. M. Pleskatchevskii, “The mathematical simulation of free boundary evolution in frictional contact,” Boundary Elem. Commun. J., 12, No. 2/3, 18–33 (2001).

G. Wei and S. F. Edvards, Phys. Rev. E, 58, No. 5b, 6173–6181 (1998).

B. S. Kolupaev, Yu. S. Lipatov, V. I. Nikitchuk, N. A. Bordyuk, and O. M. Voloshin, Inzh.-Fiz. Zh., 67, No. 5, 726–733 (1996).

T. Akasaka, “Elastic composites,” in: T.-V. Chu and F. Ko (eds.), Woven Structural Composites [Russian translation], Mir, Moscow (1991).

K. Gerakovich, “Edge effects in layered composites,” in: Yu. M. Tarnopol’skii (ed.), Applied Mechanics of Composites [in Russian], Mir, Moscow (1989), pp. 295–341.

M. Miki and Y. Morotsu, “The peculiar behavior of the Poisson’s ratio of laminated fibrous composites,” JSME Int. J., 32, 67–72 (1989).

G. W. Milton, “Composite materials with Poisson’s ratios close to −1,” J. Mech. Phys. Solids, 40, 1105–1137 (1992).

P. S. Theocaris, G. E. Stavroulakis, and P. D. Panagiotopoulus, “The homogenization method for the study of variation of Poisson’s ratio in fiber composites,” Arch. Appl. Mech., 67, 274–286 (1997).

A. K. Malmeister, V. P. Tamuzh, and G. A. Teters, Strength of Rigid Polymer Materials [in Russian], Zinatne, Riga (1972).

Author information

Authors and Affiliations

Additional information

__________

Translated from Mekhanika Kompozitnykh Materialov, Vol. 42, No. 5, pp. 681–692, September–October, 2006.

Rights and permissions

About this article

Cite this article

Shil’ko, S.V., Petrokovets, E.M. & Pleskachevskii, Y.M. An analysis of contact deformation of auxetic composites. Mech Compos Mater 42, 477–484 (2006). https://doi.org/10.1007/s11029-006-0058-8

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11029-006-0058-8