Abstract

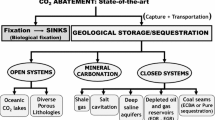

Several technical methods are currently discussed to meet the objectives of the United Nations Framework Convention on Climate Change 21st Conference of the Parties, Paris, France (Paris Agreement) in terms of carbon dioxide (CO2) concentration in the Earth’s atmosphere. In addition to efficiency improvements, reduction of energy consumption, and the utilization of renewable energy sources, the application of carbon capture and storage (CCS) technologies seems to be unavoidable. Whereas all these measures aim on the reduction of CO2 that is being newly released, there is the approach to remove CO2 from the atmosphere that has already been emitted. This can be achieved by the utilization of bioenergy in CCS processes. Within this paper, the utilization of alternative fuels in two second-generation CCS processes is assessed. In this regard, chemical looping combustion (CLC) and calcium looping (CaL) are two promising technologies. Both processes have proven their feasibility already in semi-industrial scale. The assessment includes three different types of fuel namely coal, biomass, and solid recovered fuel (SRF). The analysis is twofold: first, a heat and mass balance calculation reveals the specific CO2 emissions of each power system; second, a cost analysis points out the feasibility from an economic point of view. The highest CO2 removal can be achieved by a biomass-fired CLC unit (− 696 gCO2/kWhe). Furthermore, it was found that the co-combustion of SRF even at moderate co-firing rates allows for noteworthy improved economics of the CCS system. Therefore, the utilization of waste-derived fuels in the context of CCS processes should be put more into focus in future research activities.

Similar content being viewed by others

References

Abad A, Adánez-Rubio I, Gayán P, García-Labiano F, Diego LF, Adánez J (2012) Demonstration of chemical-looping with oxygen uncoupling (CLOU) process in a 1.5 kWth continuously operating unit using a Cu-based oxygen-carrier. Int J Greenhouse Gas Control 6:189–200

Abanades JC, Grasa G, Alonso M, Rodriguez N, Anthony EJ, Romeo LM (2007) Cost structure of a post-combustion CO2 capture system using CaO. Environ Sci Technol 41:5523–5527

Abanades JC, Arias B, Lyngfeld A, Mattisson T, Wiley DE, Li H, Ho MT, Mangano E, Brandani S (2015) Emerging CO2 capture systems. Int J Greenhouse Gas Control 40:126–166

Adanez J, Abad A, Garcia-Labiano F, Gayan P, de Diego LF (2012) Progress in chemical-looping combustion and reforming technologies. Prog Energy Combust Sci 38:215–282

Adánez J, Abad A, Mendiara P, Gayan P, Diego LF, Garcia-Labiano F (2018) Chemical looping combustion of solid fuels. Prog Energy Combust Sci 65:6–66

Bui M, Adjiman CS, Bardow A, Anthony EJ, Boston A, Brown S, Fennell PS, Fuss S, Galindo A, Hackett LA, Hallett JP, Herzog HJ, Jackson G, Kemper J, Krevor S, Maitland GC, Matuszewski M, Metcalfe IS, Petit C, Puxty G, Reimer J, Reiner DM, Rubin ES, Scott SA, Shah N, Smit B, Trusler JPM, Webley P, Wilcox J, Dowell NM (2018) Carbon capture and storage (CCS): the way forward. Energy Environ Sci 11:1062–1176

Chamberland, Andrus R H, Edberg C (2015) Alstom’s Chemical looping combustion technology with CO2 capture for new and existing coal-fired power plants. U.S. DOE/NETL CO2 Capture Technology Meeting

Chang MH, Chen WC, Huang CM, Lui WH, Chou YC, Chang WC, Chen W, Cheng JY, Huang KW, Hsu HW (2014) Design and experimental testing of a 1.9 MWth calcium looping pilot plant. Energy Procedia 63:2100–2108

Coal commodity stock exchange (2018) https://www.finanzen.net/rohstoffe/kohlepreis/euro. Accessed 27 August 2018

Cormos CC (2014) Economic evaluation of coal-based combustion and gasification power plants with post-combustion CO2 capture using calcium looping cycle. Energy 78:665–673

Del Zotto L, Tallini A, Di Simone G, Molinari G, Cedola L (2015) Energy enhancement of solid recovered fuel within systems of conventional thermal power generation. Energy Procedia 81:319–338

Dieter H, Hawthorne C, Zieba M, Scheffknecht G (2013) Progress in calcium looping post combustion CO2 capture: successful pilot scale demonstration. Energy Procedia 37:46–56

DOE/NETL (2007) Carbon dioxide capture from existing coal-fired power station. U. S Department of Energy, National Energy Technology Laboratory

European CO2 Emission Allowances (2018) https://www.finanzen.net/rohstoffe/co2-emissionsrechte. Accessed 27 August 2018

Garg A, Smith R, Hill D, Longhurst PJ, Pollard SJT, Simms NJ (2009) An integrated appraisal of energy recovery options in the United Kingdom using solid recovered fuel derived from municipal solid waste. Waste Manag 29:2289–2297

Ge H, Guo W, Shen L, Song T, Xiao J (2016) Biomass gasification using chemical looping in a 25 kWth reactor with natural hematite as oxygen carrier. Chem Eng J 286:174–183

Hanak DP, Eranz M, Nabavi SA, Jeremias M, Romeo LM, Manovic V (2018) Technical and economic feasibility evaluation of calcium looping with no CO2 recirculation. Chem Eng J 335:763–773

Helbig M, Hilz J, Haaf M, Daikeler A, Ströhle J, Epple B (2017) Long-term carbonate looping testing in a 1 MWth pilot plant with hard coal and lignite. Energy Procedia 114:179–190

Hilber T, Maier J, Scheffknecht G, Agraniotis M, Grammelis P, Kakaras E, Glorius T, Becker U, Derichs W, Schiffer HP, De Jong M, Torri L (2007) Advantages and possibilities of solid recovered fuel cocombustion in the European energy sector. J Air Waste Manage Assoc 57(10):1178–1189

Hilz J, Helbig M, Haaf M, Daikeler A, Ströhle J, Epple B (2017) Long-term pilot testing of the carbonate looping process in 1 MWth scale. Fuel 210:892–899

Hilz J, Helbig M, Haaf M, Daikeler A, Ströhle J, Epple B (2018) Investigation of the fuel influence on the carbonate looping process in 1 MWth scale. Fuel Process Technol 169:170–177

Iacovidou E, Hahladakis J, Deans I, Velis C, Purnell (2018) Technical properties of biomass and solid recovered fuel (SRF) co-fired with coal: impact on multi-dimensional resource recovery value. Waste Manag 73:535–545

IEA (2011) Combining bioenergy with CCS. Reporting and accounting for negative emissions under UNFCCC and Kyoto protocol. OECD/IEA, Paris, France

IEA (2015) CO2 emissions from fuel combustion. Paris, France

IEAGHG (2011) Potential for biomass and carbon dioxide capture and storage. Report 2011/06. IEA Greenhouse R&D Programme, Cheltenham, UK

IPCC (2005) Special report on carbon dioxide capture and storage. Cambridge University Press, Cambridge, United Kingdom and New York, USA

IPCC (2011) IPCC special report on renewable energy sources and climate change mitigation. Prepared by Working Group III of the Intergovernmental Panel on Climate Change. Cambridge University Press, Cambridge, United Kingdom and New York, USA

IPCC (2014) Climate change 2014: mitigation of climate change. Working Group III Contribution to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change. Cambridge University Press, Cambridge, United Kingdom

Johannsson T, Nakicenovic N, Patwardhan A, Gomez-Echeverri L, Turkenburg W (2012) Summary for policymakers. Global energy assessment—towards a sustainable future (eds Johansson TB, Nakicenovic N, Patwardhan A, Gomez-Echeverri L), pp. 3-30. Cambridge University press, International Institute for Applied System Analysis, Laxenburg, Austria, Cambridge, UK and New York, NY

Jordal K, Voldsund M, Storset S, Fleiger K, Ruppert J, Spörl R, Hornberger M, Cinti G (2017) CEMCAP—making CO2 capture retrofittable to cement plants. Energy Procedia 114:6175–6180

Junk M (2017) Technical and economical assessment of various carbonate looping process configurations. Dissertation, Technische Universität Darmstadt. Cuvillier Verlag, ISBN: 9783736994485

Kemper J (2015) Biomass and carbon dioxide capture and storage: a review. Int J Greenhouse Gas Control 40:401–430

Koornneef JV, Breevoort P, Hamelinck C, Hendriks C, Hoogwijk M, Koop K, Koper M, Dixon T, Camps A (2012) Global potential for biomass and carbon capture dioxide capture, transport and storage up to 2050. Int J Greenhouse Gas Control 11:117–132

Li K, Leigh W, Feron P, Yu H, Tade M (2016) Systematic study of aqueous monoethanolamine (MEA)-based CO2 capture process: techno-economic assessment of the MEA process and its improvements. Appl Energy 165:648–659

Lyngfelt A, Leckner B (2015) A 1000 MWth boiler for chemical-looping combustion of solid fuels—discussion of design and costs. Appl Energy 157:475–487

Manzolini G, Fernandez ES, Rezvani S, Macchi E, Goetheer ELV, Vlugt TJH (2015) Economic assessment of novel amine based CO2 capture technologies integrated in power plants based on European Benchmarking Task Force methodology. Appl Energy 138:546–558

Markström P, Linderholm C, Lyngfelt A (2013) Chemical-looping combustion of solid fuels—design and operation of a 100 kW unit with bituminous coal. Int J Greenhouse Gas Control 15:150–162

Ohlemüller P, Busch JP, Reitz M, Ströhle J, Epple B (2016) Chemical-looping combustion of hard coal: autothermal operation of a 1 MWth pilot plant. J Energy Resourc Technol 138:042203-042203-7

Ohlemüller P, Ströhle J, Epple B (2017) Chemical looping combustion of hard coal and torrefied biomass in a 1 MWth pilot plant. Int J Greenhouse Gas Control 65:149–159

Ohlemüller P, Olausson M, John M, Alobaid F, Ströhle J, Epple B (2018) Thermodynamic and economic evaluation of a full-scale chemical looping plant. 5th International Conference on Chemical Looping, Utah, USA

Ozcan DC, Hyungwoong A, Brandani S (2013) Process integration of a Ca-looping carbon capture process in a cement plant. Int J Greenhouse Gas Control 19:530–540

Pera-Titus M (2013) Porous inorganic membranes for CO2 capture: present and prospects. Chem Rev 114:1413–1492

Raksajati A, Ho MT, Wiley DE (2013) Reducing the cost of CO2 capture from flue gases using aqueous chemical absorption. Ind Eng Chem Res 52:16887–16901

Rodriguez N, Alonso M, Abanades JC (2011) Experimental investigations of a circulating fluidized-bed reactor to capture CO2 with CaO. AICHE J 57:1356–1366

Rolfe A, Huang Y, Haaf M, Rezvani S, McIlveen-Wright D, Hewitt NJ (2018) Integration of the calcium carbonate looping process into an existing pulverized coal-fired power plant for CO2 capture: techno-economic and environmental evaluation. Appl Energy 222:169–179

Romeo LM, Lara Y, Lisbona P, Martìnez A (2009) Economical assessment of competitive enhanced limestones for CO2 capture cycles in power plants. Fuel Process Technol 90:803–811

Rubin ES, Booras G (2012) Toward a common method of cost estimation for CO2 capture and storage. Proceedings of CCS Cost Workshop, Palo Alto, USA

San-Perez AS, Murdock RC, Didas AS, Jones WC (2016) Direct capture of CO2 from ambient air. Chem Rev 116:11840–11876

Schaupp D (2014) Economic analysis of the calcium looping process. CAL-MOD Workshop. https://www.pre-sustainability.com/download/DatabaseManualMethods.pdf. Accessed 27 August 2018

Shen L, Wu J, Xiao J, Song Q, Xiao R (2009) Chemical-looping combustion of biomass in a 10 kWth reactor with Iron oxide as an oxygen carrier. Energy Fuel 23:2498–2505

Shimizu T, Hirama T, Hosoda H, Kitano K, Inagaki M, Tejima K (1999) A twin fluid-bed reactor for removal of CO2 from combustion processes. Institution of Chemical Engineers 77:62–68

Ströhle J, Lasheras A, Galloy A, Eppe B (2009) Simulation of the carbonate looping process for post-combustion CO2 capture from a coal-fired power plant. Chem Eng Technol 32:435–442

Ströhle J, Junk M, Kremer J, Galloy A, Epple B (2014) Carbonate looping experiments in a 1 MWth pilot plant and model validation. Fuel 127:13–22

Teixeria P, Lopes H, Gulyurtlu I, Lapa N, Abelha P (2012) Evaluation of slagging and fouling tendency during biomass co-firing with coal in a fluidized bed. Biomass Bioenergy 39:192–203

Thon A, Kramp M, Hartge EU, Heinrich S, Werther J (2014) Operational experience with a system of coupled fluidized beds for chemical looping combustion of solid fuels using ilmenite as oxygen carrier. Appl Energy 118:309–317

Wang P, Means N, Shekhawat D, Berry D, Massoudi M (2015) Chemical-looping combustion and gasification of coals and oxygen carrier development: a brief review. Energies 8:10605–10635

Yang Y, Rongrong Z, Liqiang D, Kavosh M, Patchigolla K, Oakey J (2010) Integration and evaluation of a power plant with a CaO based CO2 capture system. Int J Greenhouse Gas Control 4:603–612

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Haaf, M., Ohlemüller, P., Ströhle, J. et al. Techno-economic assessment of alternative fuels in second-generation carbon capture and storage processes. Mitig Adapt Strateg Glob Change 25, 149–164 (2020). https://doi.org/10.1007/s11027-019-09850-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11027-019-09850-z