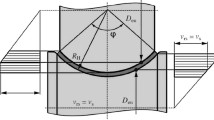

We describe the results of an experimental study of longitudinal and transverse variations in wall thickness at the ends of pipes after rolling in a stretch-reducing mill (SRM). We found that the largest “contribution” to the scatter in wall thickness comes from internal hexagon produced in the pipes by the reduction-mill drawing schedule and the roll pass design. A mathematical model was developed based on current high-speed SRM mode calculation procedures, and the plastic tension coefficients, rolling diameters, and roller speeds for each SRM stand in steady-state rolling mode were calculated. The pipe wall thicknesses calculated using the mathematical model were similar to those obtained experimentally. The accuracy of the pipe inside diameter was determined.

Similar content being viewed by others

Notes

State Software Registration Certificate No. 2015660153, V. B. Timofeev, A. S. Anan’ev, I. B. Medyantsev, and S. I. Zaboev, Automatic Control of Stand Drives on a TESA 20-102 Stretch-Reducing Mill to Maintain Constant Wall Thickness of Finished Pipes, registration date 23 September 2015.

References

V. L. Kolmogorov, Theory of Pressure Working of Metals [in Russian], UGTU-UPI, Ekaterinburg (2001).

A. F. Danilov, A. Z. Gleiberg, and V. G. Balakin, Hot Rolling and Pressing of Pipe [in Russian], 3rd ed., Revised and Enlarged, Metallurgiya, Moscow (1972).

V. N. Danchenko, A. P. Kolikov, and B. A. Romantsev, Pipe Production Technology [in Russian], Intermet Inzhiniring, Moscow (2002).

Yu. F. Shevakin, A. P. Kolikov, and Yu. N. Raikov, Pipe Production [in Russian], Intermet Inzhiniring, Moscow (2005).

G. I. Gulyaev, P. N. Ivshin, and I. N. Erokhin, Technology for Continuous Mandrelless Rolling of Pipe [in Russian], Metallurgiya, Moscow (1975).

M. F. Stoletnii and E. D. Klempert, Pipe Precision [in Russian], Metallurgiya, Moscow (1975).

I. N. Potapov, A. P. Kolikov, and V. M. Druyan, Theory of Pipe Production [in Russian], Metallurgiya, Moscow (1991).

V. Ya. Osadchii, A. S.Vavilin, V. G. Zimovets, and A. P. Kolikov, Processes and Equipment for Pipe Manufacturing: A Textbook for Institutions of Higher Learning [in Russian], Intermet Inzhiniring, Moscow (2007).

B. A. Romantsev, A. V. Goncharuk, N. M. Vavilkin, and S. V. Samusev, Pipe Manufacturing [in Russian], ID MISiS, Moscow (2011).

V. V. Eriklintsev, D. S. Fridman, and N. A. Bogatov, Practical Experience in Continuous Stretch Reduction of Pipe [in Russian], Sred.-Ural. kn. izd-vo, Sverdlovsk (1966).

V. V. Eriklintsev, Yu. I. Blinov, D. S. Fridman, et al., Theory of Pipe Reduction [in Russian], Sredne-Ural. Kn. Izd-vo, Sverdlovsk (1970).

This work was performed with the support of Russian Federation Presidential Grant MK-3011.2017.8.

Author information

Authors and Affiliations

Corresponding author

Additional information

A. A. Bogatov is Deceased

Translated from Metallurg, Vol. 62, No. 6, pp. 65–70, May 2018.

Rights and permissions

About this article

Cite this article

Bogatov, A.A., Pavlov, D.A., Timofeev, V.B. et al. Theoretical and Experimental Study of Non-Steady-State Pipe Reduction Process Using a Tesa 20-102 Mill. Metallurgist 62, 559–567 (2018). https://doi.org/10.1007/s11015-018-0693-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-018-0693-z