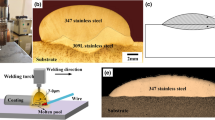

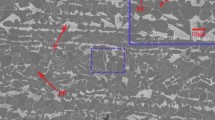

The correlation of hardness, microstructure, and dilution with the abrasion mass loss of hardfaced samples deposited using different currents (500 and 600 A) and polarities (AC and DC+) was studied. Four different welding conditions were considered for submerged arc welding using a martensitic hardfacing electrode and austenitic buffer electrode. Single-layer hardfacing was applied over the single-layer buffer. The microstructure of hardfacing was observed by an optical microscope. The micro-Vickers hardness across a single-layer hardfacing and dilution percentage were also measured. A dry-sand–rubber wheel abrasion test was conducted according to ASTM G65 procedure A to record the abrasive mass loss of the samples. The use of higher current and DC+ polarity resulted in the highest mass loss because of the deepest dilution and lowest hardness. Dilution affects the hardness and microstructure of hardfacing. The lowest abrasive mass loss, shallowest dilution, and highest hardness were obtained for the sample welded with lower current and AC polarity.

Similar content being viewed by others

References

A. Saha and S. C. Mondal, “Multi-objective optimization of manual metal arc welding process parameters for nano-structured hardfacing material using hybrid approach,” Measurement, 102, 80–89 (2017).

K. G. Budinski and S. T. Budinski, “On replacing three-body abrasion testing with two-body abrasion testing,” Wear, 376, 1859–1865 (2017).

C. Wang, X. Li, Y. Chang, S. Han, and H. Dong, “Comparison of three-body impact abrasive wear behaviors for quenching–partitioning–tempering and quenching–tempering 20Si2Ni3 steels,” Wear, 362, 121–128 (2016).

E. Correa, N. Alcântara, L. Valeriano, et al., “The effect of microstructure on abrasive wear of a Fe–Cr–C–Nb hardfacing alloy deposited by the open arc welding process,” Surf. Coat. Technol., 276, 479–484 (2015).

N. Yüksel and S. Şahin, “Wear behavior–hardness microstructure relation of Fe–Cr–C and Fe–Cr–C–B based hardfacing alloys,” Mater. Des., 58, 491–498 (2014).

X. Wang, F. Han, and S. Qu, “Microstructure of the Fe-based hardfacing layers reinforced by TiC–VC–Mo2C particles,” Surf. Coat. Technol., 202, No. 8, 1502–1509 (2008).

American Society for Metals, Welding, Brazing and Soldering: Metals Handbook, Metals Park, Ohio (1983), 9th ed., Vol. 6, p. 2873.

R. Bendikiene and L. Kavaliauskiene, “The effect of plastic deformation rate on the wear performance of hardfaced coatings,” Weld. World, 61, No. 5, 1–8 (2017).

J. H. Bulloch and J. L. Henderson, “Some considerations of wear and hardfacing materials,” Int. J. Press. Vess. Piping, 46, No. 3, 251–267 (1991).

M. Morsy and E. El-Kashif, “The effect of microstructure on high-stress abrasion resistance of Fe–Cr–C hardfacing deposits,” Weld. World, 58, No. 4, 491–497 (2014).

C. Fang, Y. Chen, Z. Yang, et al., “Cable-type welding wire submerged arc surfacing,” J. Mater. Process. Technol., 249, 25–31 (2017).

M. Kirchgaßner, E. Badisch, and F. Franek “Behaviour of iron-based hardfacing alloys under abrasion and impact,” Wear, 265, No. 5–6, 772–779 (2008).

K. Yang, S. Yu, Y. Li, and C. Li, “Effect of carbonitride precipitates on the abrasive wear behaviour of hardfacing alloy,” Appl. Surf. Sci., 254, No. 16, 5023–5027 (2008).

S. Chatterjee and T. K. Pal, “Weld procedural effect on the performance of iron based hardfacing deposits on cast iron substrate,” J. Mater. Process. Technol., 173, No. 1, 61–69 (2006).

A. C. Crespo, A. Scotti, and M. R. Pérez, “Operational behavior assessment of coated tubular electrodes for SMAW hardfacing,” J. Mater. Process. Technol., 199, No. 1, 265–273 (2008).

H. L. Tsai, Y. S. Tarng, and C. M. Tseng, “Optimisation of submerged arc welding process parameters in hardfacing,” Int. J. Adv. Manuf. Technol., 12, No. 6, 402–406 (1996).

K. Siva, N. Murugan, and R. Logesh, “Optimization of weld bead geometry in plasma transferred arc hardfaced austenitic stainless-steel plates using genetic algorithm,” Int. J. Adv. Manuf. Technol., 41, No. 1, 24–30 (2009).

K. Marimuthu and N. Murugan, “Prediction and optimisation of weld bead geometry of plasma transferred arc hardfaced valve seat rings,” Surf. Eng., 19, No. 2, 143–149 (2003).

ASTM International, G65-16: Standard Test Method for Measuring Abrasion Using the Dry Sand/Rubber Wheel, ASTM Standards 04 (2013), pp. 1–12.

X. Wang, F. Han, and S. Qu, “Microstructure of the Fe-based hardfacing layers reinforced by TiC–VC–Mo 2 C particles,” Surf. Coat. Technol., 202, No. 8, 1502–1509 (2008).

Acknowledgments

This work was supported by the Higher Education Research Promotion and the Thailand’s Education Hub for Southern Region of ASEAN Countries Project Offi ce of the Higher Education Commission. The authors would like to acknowledge the Department of Mining and Materials Engineering, Faculty of Engineering, Prince of Songkla University, Hat Yai Campus, Thailand for supporting equipment, and the Electricity Generating Authority of Thailand (EGAT), Mae Moh Lignite Mine, Thailand for some data of this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Oo, H.Z., Srikarun, B. & Muangjunburee, P. Correlating Hardness and Welding Dilution with the Abrasion Mass Loss of Hardfacings Welded with Different Currents and Polarities. Metallurgist 61, 1033–1037 (2018). https://doi.org/10.1007/s11015-018-0604-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-018-0604-3