The uniaxial-compression creep behavior of semi-graphitic carbon products was investigated using modified Rapoport equipment in a K3AlF6–Na3AlF6–AlF3 and a Na3AlF6–AlF3 system. The stress exponent is low for the K3AlF6–Na3AlF6–AlF3 system in the steady-state creep stage. With an increase in graphitization degree and grain size, the interlayer space and porosity of the tested samples decrease after aluminum electrolysis. A low temperature can suppress carbon-cathode damage. Based on these stress exponents and a microstructural investigation using transmission electron microscopy, it is proposed that dislocation glide is the dominant creep mechanism for the carbon cathode during aluminum electrolysis in the steady-state creep stage.

Similar content being viewed by others

Change history

30 January 2018

The Acknowledgment at the end of the paper should read: Financial support from the National Natural Science Foundation of China (NSFC) (No. 170410656) and the Collaborative Innovation Center of Nonferrous Metals, Henan Province (15A450001) is gratefully acknowledged.

References

H. W. Yan, J. H. Yang, W. X. LI, et al., “Alumina solubility in KF–NaF–AlF3-based low-temperature electrolyte,” Metall. Mater. Trans. B, 42, No. 5, 1065–1070 (2011).

J. Frazer and J. Thonstad, “Alumina solubility and diffusion coefficient of the dissolved alumina species in low-temperature fluoride electrolytes,” Metall. Mater. Trans. B, 41, No. 3, 543–548 (2010).

M. Yuan, S. Kan, Q. Meng, et al., “Effect of LiF and Al2O3 on the physical and chemical characters in elpasolite containing aluminium electrolyte system,” Rare Met. , 30, No. 1, 595–598 (2011).

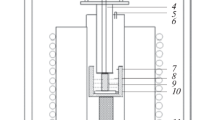

A. Zolochevsky, J. G. Hop, T. Foosnaes, et al., “Rapoport–Samoilenko test for cathode carbon materials-II. Swelling with external pressure and effect of creep,” Carbon, 43, No. 6, 1222–1230 (2005).

T. Chen, J. L. Xue, and X. Li, “High-temperature creep deformation and change in porous structure of graphite cathode in aluminum electrolysis process,” Light Met., 123–130 (2014).

G. V. Arkhipov and Y. S. Gorlanov, “Development of technology for producing a wettable coating on a carbon cathode by electrodeposition,” Light Met., 1367–1372 (2012).

D. Picard, M. Fafard, G. Soucy, et al. “Room temperature long-term creep/ relaxation behaviour of carbon cathode material,” Mater. Sci. Eng., A, 496, No. 1, 366–375 (2008).

A. Zolochevsky, J. G. Hop, G. Servant, et al. “Rapoport–Samoilenko test for cathode carbon materials: I. Experimental results and constitutive modelling,” Carbon, 41, No. 3, 497–505 (2003).

Z. Fang, X. L. Wu, J. Yu, et al., “Penetrative and migratory behavior of alkali metal in different binder based TiB2-C composite cathodes,” Trans. Nonferr. Met. Soc, 24, No. 4, 1220–1230 (2014).

T. Gruber, T. W. Zerda, and M. Gerspacher, “Raman studies of heat-treated carbon blacks,” Carbon, 32, No. 7, 1377–1382 (1994).

J. Li, Y. Y. Wu, Y. Q. Lai, et al., “Simulation of thermal and sodium expansion stress in aluminum reduction cells,” J. Cent. South Univ., 15, 198–203 (2008).

W. Wang, J. L. Xue, J. Q. Feng, et al., “Creep behaviors of industrial graphitic and graphitized cathodes during modified Rapoport tests,” Light Met., 1053–1057 (2011).

Y. H. Zhang, N. X. Feng, J. P. Peng, et al., “Effect of KF additions in Na3AlF6–Al2O3 electrolytes on expansion of cathode blocks,” Light Met., 681–684 (2012).

J. L. Xue, Q. S. Liu, and B. S. Li, “Creep deformation in TiB2/C composite cathode materials for aluminum electrolysis,” Light Met., 1023–1027 (2008).

X. Li, J. L. Xue, J. Zhu, et al., “Analysis of porous structures of graphitic cathode materials and the correlation to penetrated sodium,” Light Met., 1319–1324 (2012).

J. L. Xue, L. C. Wu, W. Wang, et al., “Characterization of sodium expansion of industrial graphitic and graphitized cathodes,” Light Met., 849–853 (2010).

Q. Y. Lin, T. Q. Li, Z. J. Liu, et al., “High-resolution TEM observations of isolated rhombohedral crystallites in graphite blocks,” Carbon, 50, No. 6, 2369–2371 (2012).

F. Kabirian and R. Mahmudi, “Impression creep behavior of a cast AZ91 magnesium alloy,” Mater. Trans. A, 40, No. 1, 116–127 (2009).

E. G. Zukas and W. V. Green, “High temperature creep of a poco graphite,” Carbon, 10, No. 3, 519–522(1972).

N. Luiggi and M. Gómez, “Rhombohedral graphite: Comparative study of the electronic properties,” J. Mol. Struct.: Theochem, 897, No. 1, 118–128 (2009).

P. Y. Brisson, H. Darmstadt, M. Fafard, et al., “x-Ray photoelectron spectroscopy study of sodium reactions in carbon cathode blocks of aluminium oxide reduction cells,” Carbon, 44, No. 8, 1438–1447 (2006).

D. G. Liu, Z. H. Yang, W. X. Li, et al., “Electrochemical intercalation of potassium into graphite in KF melt,” Electrochim. Acta, 55, No. 3, 1013–1018 (2010).

X. G. Lü, Q. Y. Li, Y. Q. Lai, et al., “Digital characterization and mathematic model of sodium penetration into cathode material for aluminum electrolysis,” J. Cent. South. Univ., 16, 96–100 (2009).

M. B. Rapoport and V. N. Samoilenko, “Deformation of cathode blocks in aluminium baths during process of electrolysis,” Tsvet. Met., 30, No. 2, 44–51(1957).

A. Zolochevsky, J. G. Hop, T. Foosnaes, et al., “Surface exchange of sodium, anisotropy of diffusion and diffusional creep in carbon cathode materials,” Light Met., 745–750 (2005).

Acknowledgments

Financial support from the Collaborative Innovation Center of Nonferrous Metals Henan Province (15A450001) is gratefully acknowledged.

Author information

Authors and Affiliations

Additional information

A correction to this article is available online at https://doi.org/10.1007/s11015-018-0582-5.

Rights and permissions

About this article

Cite this article

Wang, W., Chen, W. & Gu, W. Creep Deformation of Carbon-Based Cathode Materials for Low-Temperature Aluminum Electrolysis. Metallurgist 61, 717–725 (2017). https://doi.org/10.1007/s11015-017-0555-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-017-0555-0