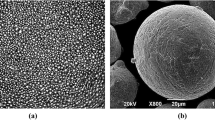

Conditions are analyzed for powder steel formation with electric-contact compaction (ECC). Areas of production regimes with different ratios of moving and retarding surface consolidation between interparticle surface growth (IPSG) migration forces and areas of ECC production regimes, providing homogenization of an iron-graphite charge and high quality consolidation between particles, are indicated. The dependence of steel true ultimate strength on electric-contact compaction regime is considered.

Similar content being viewed by others

References

S. N. Egorov, Yu. Yu. Medvedev, M. S. Egorov, and I. F. Egorova, RF Patent 2210460 IPC7 B22F3/105, Method for Preparing Objects from Charges Based on Metal Powder, subm. 12.06.2001, publ. 08.20.2003.

Yu. Yu. Medvedev, “Structure of powder material formed during electroplastic compaction of iron powder,” Mater. 7th Int. Sci. Pract. Conf. Engineering Problems and Material Technology at the Turn of the Century, May 28–30, 2003, Penza State Univ., Penza (2003), pp. 47–49.

A. A. Metsler, “Powder bond structure formation with electroplastic compaction,” Metallurg, No. 5, 66–67 (2007).

T. A. Litvinova, Formation of Powder Steel by Electric-Contact Compaction: Diss. Cand. Tech. Sci., Novocherkassk (2010).

T. A. Litvinova, “Homogenization of powder steel during formation under conditions of electric-contact compaction,” Mater. 7th Int. Sci. Tech. Conf. Improvement of Production Efficiency for Electric Power, Sept. 30, 2009, URGTU (NPI), Novocherkassk (2009).

Yu. Yu. Medvedev, Formation of Powder Material with Electroplastic Compaction: Diss. Cand. Tech. Sci., Novocherkassk (2003).

T. A. Litvinova and S. N. Egorov, “Effect of production regimes for electric-contact compaction on powder porosity,” Izv. Vyssh. Uchebn. Zaved., Poroshk. Metall. Funks. Pokrytiya, No. 1, 28–30 (2010).

V. Yu. Dorofeev and S. N. Egorov, Interparticle Consolidation During Formation of Powder Hot-Worked Materials [in Russian], Metallurgizdat, Moscow (2003).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, No. 4, pp. 94–97, April, 2013.

Rights and permissions

About this article

Cite this article

Litvinova, T.A., Egorov, S.N. Features of Powder Steel Formation with Electric-Contact Compaction. Metallurgist 57, 342–345 (2013). https://doi.org/10.1007/s11015-013-9735-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-013-9735-8