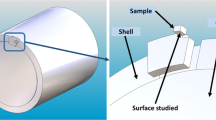

Study of the nature of low-carbon structural steel rolled product surface defects by a metallographic method makes it possible to establish that formation of flaws in rolled product in the bottom part of ingots is connected with the presence of gas bubbles and extraneous inclusions. The effect of aluminum on rolled product surface quality is analyzed. The optimum aluminum content in steels 09G2S – 0.011–0.015%, S355j2G3 – 0.021–0.025% is established, and this makes it possible to improve metal ductility, reduce the degree of ingot defect development, and reduce rolled product rejection for surface defects.

Similar content being viewed by others

References

Yu. Aizenkolb, R. Fandrikh, and H. P. Yung, “Contemporary state of ingot casting and remelting,” Chern. Met., No. 1, 33–42 (2011).

V. D. Trofimchuk, Rolled Steel Defects [in Russian], Gos. Nauch.-Tekhn. Izd. Lit. Chern. Tsvet. Met., Moscow (1954).

S. M. Novokshchenova and M. I. Vinograd (eds.), Steel Defects: Handbook [in Russian], Metallurgiya, Moscow (1984).

G. A. Buryakovskii, Alloy Steel Surface Defects [in Russian], Metallurgiya, Moscow (1987).

V. A. Parshin, Deformability and Quality [in Russian], Metallurgiya, Moscow (1979).

P. P. Mukhina and O. N. Zorina, “Prevention of surface defect formation in steel 20 blooms,” Stal, No. 3, 61–62 (1998).

V. G. Pisarenko et al., “Effect of production factors for rolled product manufacture on the defectiveness of billets of the Krivorozhstal Combine rolling workshop,” Proizvod. Prokata, No. 10, 27–30 (2004).

I. S. Kuznetsov et al., “Effect of production factors on structural steel billet surface quality,” Stal, No. 4, 44–46 (2008).

M. V. Zezikov, P. M. Shipulin, and V. V. Salomykin, “Study of heating ingot heating and rolling regimes for carbon structural and high quality steels,” Stal, No. 8, 53–54 (1988).

V. V. Alchin, V. N. Artyushov, and E. M. Komelnikov, “Improvement of steel S355j2G3 billet quality,” Stal, No. 7, 50–51 (2007).

A. N. Tumko, S. V. Revyakin, and N. M. Ternovskaya, “Study of the effect of ingot temperature during charging in heated soaking pits on rolled product surface quality,” Met. Gorn. Prom. No. 2, 48–50 (2001).

V. V. Averin, A. V. Revyakin, V. I. Fedorchenko, et al., Nitrogen in Metals [in Russian], Metallurgiya, Moscow (1976).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, No. 10, pp. 66–69, October, 2012.

Rights and permissions

About this article

Cite this article

Rubezhanskaya, I.V., Pozdnysheva, Y.A., Zyuban, N.A. et al. Ways of improving the quality of the surface of rolled products made of low-carbon structural steel ingots. Metallurgist 56, 773–778 (2013). https://doi.org/10.1007/s11015-013-9649-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-013-9649-5