This article examines technological aspects of the use of superhigh-pressure fluids for the hot extrusion, cold extrusion, and compaction of powders at pressures up to 2000 MPa. New methods for the hot extrusion and hot compaction of powders by superhigh-pressure fluids are described. Some results are presented from use of the new technology of shaping materials with superhigh-pressure fluid.

Similar content being viewed by others

Notes

“Vitrification” here means the conversion of an amorphous substance from the liquid state to the solid state at high pressures.

This does not apply to the production of membranes for filters, when the objective of the process is to obtain a porous material.

References

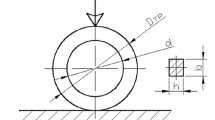

V. M. Lugovskoi, “Working chambers for shaping materials with a fluid at superhigh pressure,” Metallurg, No. 11, 57–61 (2010).

P. W. Bridgeman, The Latest Advances in High Pressure [Russian translation], IL, Moscow (1948).

B. I. Beresnev, A. T. Gaivoronskii, V. K. Zamaraev, and A. A. Khamitov, Hydrostatic Extrusion [in Russian], Inst. Prikl. Mekhaniki, UrO RAN, Ekaterinburg (1998).

R. A. Andrievskii, Powder Metallurgy [in Russian], Metallurgiya, Moscow (1991).

Author information

Authors and Affiliations

Additional information

Translated from Metallurg, No. 3, pp. 65–68, March, 2011.

Rights and permissions

About this article

Cite this article

Lugovskoy, V.M., Danieli, G. Hot and cold shaping of materials by a fluid at superhigh pressure. Metallurgist 55, 202 (2011). https://doi.org/10.1007/s11015-011-9413-7

Received:

Published:

DOI: https://doi.org/10.1007/s11015-011-9413-7