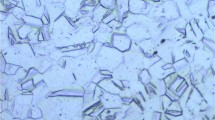

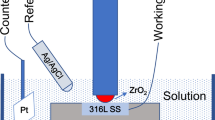

We study the influence of external polarization with different potentials on the tribocorrosion behavior of 08Kh18N10T steel in contact with a corundum ball in a 3% NaCl solution. It is shown that the mechanical factor shifts the potential of pitting formation to the negative side by 0.17 V as compared with the surface without friction. The running-in time, friction coefficient, and material losses in the process of tribocorrosion qualitatively correlate with each other and depend on the applied electrode potential. It is shown that hydrogen released in the contact zone under the conditions of cathodic polarization embrittles the surface layers participating in the contact interaction. Moreover, hydrogen reduces oxide films and prevents their rapid formation on steel, which intensifies its wear. In addition, hydrogen facilitates deformation and increases the deformation zone near the friction track. Under the anodic polarization, we observe an increase in the number of pits in the friction area.

Similar content being viewed by others

References

Yu. G. Sukhenko, O. I. Nekoz, and M. S. Stechyshyn, Technological Methods of Guaranteeing the Durability of Equipment of the Food Industry [in Ukrainian], Eleron, Kiev (1993).

M. S. Jellesen, L. R. Hilbert, and P. І. Moller, “Tribocorrosion in the food industry,” in: Proc. of Eurocorrosion 2007, Freiburg im Breisgau, Germany, September 9–13 (2007), CD-ROM, Paper No. 1259.

G. M. Sorokin, A. P. Efremov, and L. S. Saakyan, Corrosion-Mechanical Wear of Steels and Alloys [in Russian], Neft’ i Gas, Moscow (2002).

D. Landolt, S. Mischler, and M. Stemp, “Electrochemical methods in tribocorrosion: a critical appraisal,” Electrochim. Acta, 46, 3913–3929 (2001).

G. A. Preis and A. G. Dzyub, “Electrochemical phenomena in the friction of metals,” Tren. Iznos, 1, No. 2, 217–235 (1980).

V. I. Pokhmurs’kyi and V. M. Dovhunyk, “Tribocorrosion of stainless steels (Review),” Fiz.-Khim. Mekh. Mater., 46, No. 1, 76–85 (2010); English translation : Mater. Sci., 46, No. 1, 87–96 (2010).

M. T. Mathew, E. Ariza, L. A. Rocha, A. C. Fernandes, and F. Vaz, “TiCxOy thin films for decorative applications: Tribocorrosion mechanisms and synergism,” Tribology Int., 41, 603–615 (2008).

S. Mischler, S. Debaud, and D. Landolt, “Wear accelerated corrosion of passive metals in tribocorrosion systems,” J. Electrochem. Soc., 145, 750–758 (1998).

A. Bidiville, M. Favero, P. Stadelmann, and S. Mischler, “Effect of surface chemistry on the mechanical response of metals in sliding tribocorrosion systems,” Wear, 263, 207–217 (2007).

J.-P. Celis, P. Pontiaux, and F. Wenger, “Tribocorrosion of materials: interplay between chemical, electrochemical, and mechanical reactivity of surfaces,” Wear, 261, 939–946 (2006).

P.-Q. Wu and J.-P. Celis, “Electrochemical noise measurements on stainless steel during corrosion-wear in sliding contacts,” Wear, 256, 480–490 (2004).

R. J. K. Wood and A. J. Speyer, “Erosion–corrosion of candidate HVOF aluminum-based marine coatings,” Wear, 256, 545–556 (2004).

J. Stojadinovic, S. Mischler, D. Bouvet, and M. Declercq, “Tribocorrosion of tungsten: effect of potential on wear,” Tribol. Industry, 29, Nos. 1/2, 41-44 (2007).

M. Favero, P. Stadelmann, and S. Mischler, “Effect of the applied potential of the near surface microstructure of a 316 steel submitted to tribocorrosion in sulfuric acid,” J. Phys. D: Appl. Phys., 39, 3175–3183 (2006).

J. Chen, J. Wang, F. Yan, Q. Zhang, and Q. Li, “Effect of applied potential on the tribocorrosion behaviors of Monel K500 alloy in artificial seawater,” Tribology Int., 81, 1–8 (2015).

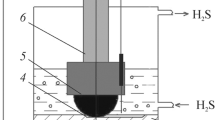

V. A. Vynar, V. M. Dovhunyk, and M. M. Student, “Methodical specific features of tribocorrosion investigations,” Fiz.-Khim. Mekh. Mater., 46, No. 5, 59–64 (2010); English translation : Mater. Sci., 46, No. 5, 633–639 (2011).

Y. Zhang, X. Yin, J. Wang, and F. Yan, “Influence of potentials on the tribocorrosion behavior of 304SS in artificial seawater,” Royal Soc. Chem. Adv., No. 4, 55752–55759 (2014).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 54, No. 2, pp. 134–139, March–April, 2018.

Rights and permissions

About this article

Cite this article

Pokhmurs’kyi, V.I., Khoma, M.S., Vynar, V.A. et al. Influence of the External Polarization Potential on the Tribocorrosion Behavior of 08Kh18N10T Steel. Mater Sci 54, 279–285 (2018). https://doi.org/10.1007/s11003-018-0184-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11003-018-0184-1