Abstract

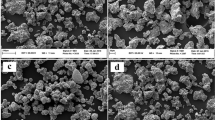

A lost carbonate sintering process in powder metallurgy has been used to prepare copper foam of low to medium porosities with controlled pore size, shape, and distribution. The compressive properties of the copper foams have been investigated for different metal volume fractions ranging from 15–100%. The elastic moduli measurements in good agreement with Mori-Tanaka predictions for the two-phase mixtures. The microstructure, the electrical resistivity, and the thermal conductivity were also studied.

Similar content being viewed by others

References

Davies, G.J., Zhen S.: Observations of the growth morphology of the intermetallic compound Al3Zr. J. Cryst. Growth 64(2), 407–410 (1983)

Electrical properties. International Annealed Copper Standard by the International Electro technical Commission (IACS) in terms of the following properties at 20°C (1913)

Erikson, R.: Foams on the cutting edge, mechanical engineering. Trans. ASME 121(1), 2–5 (1999)

Heil C., Dittman, D., Ishai, O.: Composite sandwich construction with syntactic foam core: a practical assessment of post impact damage and residual strength. J. Composites 24(5), 447–450 (1993)

Ma, X., Peyton, A.J., Zhao, Y.Y.: Eddy current measurements of electrical conductivity and magnetic permeability of porous metals. NDT E Int. 39(7), 562–568 (2006)

Meguid, S.A., Cheon, S.S., El-Abbasi, N.: FE modelling of deformation localization in metallic foams. J. Finite Elem. Anal. Des. 38(7), 631–643 (2002)

Meguid S.A., Attia M.S., Monfort, A.: On the crush behavior of ultralight foam-filled structures, Mater. Des. 25(3), 183–189 (2004)

Mori, T., Tanaka, K.: Average stress in matrix and average elastic energy of materials with misfitting inclusions. Acta Metallurgica 21, 571–574 (1973)

Nakajima, H., Hyun, S.K., Ohashi, K., Ota, K., Murakami, K.: Fabrication of porous copper by unidirectional solidification under hydrogen and its properties. J. Colloids Surf. A Physicochem. Eng. Asp. 179, 209–214 (2001)

Raymond, S.: Physics for Scientists and Engineers with Modern Physics, 3rd edn. Saunders College Publishing (1990)

Tabata, T., Masaki, S.: Estimation of flow-stress of porous sintered metals from hardness test with pyramidal and spherical indenters, J. Eng. Mater. Technol., Trans. ASME. 112(1), 95–98 (1990)

Weng, G.: Some elastic properties of reinforced solids with special reference to isotropic ones containing spherical inclusions. Int. J. Eng. Sci. 22(7), 845–856 (1984)

Xie, Z.Y., Liang, H., Xu, M.X., Xu T.X.: Solid phase reaction process of cordierite powders prepared by sol–gel method and its sintering. J. Inorg. Mater. 19(4), 779–783 (2004)

Yang, Y.J., Han, F.S., Yang, D.K., Wu, J., Hao, G.L., Wang, Q.Z.: Effect of heat treatment on compressive properties of open cell Al/Al2O3 composite foams. Powder Metrol. 50(1), 50–53 (2007)

Zhang, E., Wang, B.: On the compressive behavior of sintered porous coppers with low to medium porosities—part I: experimental study, Int. J. Mech. Sci. 47, 744–756 (2005)

Zhao, Y.Y., Fung, T., Zhang, L.P., Zhang, F.L.: Lost carbonate sintering process for manufacturing metal foams, Scr. Mater. 52, 295–298 (2005)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

El-Hadek, M.A., Kaytbay, S. Mechanical and physical characterization of copper foam. Int J Mech Mater Des 4, 63–69 (2008). https://doi.org/10.1007/s10999-008-9058-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10999-008-9058-2