Abstract

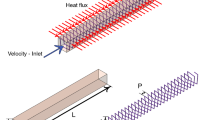

Heat transfer and flow characteristics have been numerically analyzed by using four different fluids [pure ethylene glycol (EG), TiO2/EG and Cu/EG nanofluids and 50%:50% TiO2–Cu/EG hybrid nanofluid] and changing the position, length and height of a triangular rib placed in a two-dimensional duct under forced convection and turbulent flow conditions using RNG k-epsilon turbulence model. While forming the hybrid nanofluid, all nanoparticles are added at 50–50%. A constant heat flux of 500 W m−2 is applied to the bottom wall of the duct. The Reynolds number is considered in the range of 50,000 and 100,000. Two different nanoparticle volume fractions, 1.0% and 4.0%, are used. The parameters of the rib are dimensionlized, and three different rib positions (X/H = 1, 3 and 5), lengths (S/H = 0.5, 1 and 1.5) and heights (h/H = 0.1, 0.2 and 0.3) are used. Governing equations are determined with the finite volume method. In the study, analysis of Nusselt number, Darcy friction factor (f), PEC number and velocity streamlines is performed in detail. Generally, heat transfer performance increases with increasing Reynolds number and nanoparticle volume fraction, but the increase in nanoparticle volume fraction also increases the Darcy friction factor. TiO2–Cu/EG hybrid nanofluid having the 4.0% nanoparticle volume fraction is the best heat transfer fluid. When using TiO2–Cu/EG hybrid nanofluid, the increase in the PEC number varies between 8 and 30% in the smooth duct. From the results obtained by using hybrid nanofluid in the duct with the triangular rib, it is understood that the rate of heat transfer enhances with increasing dimensionless rib position, length and height. But the most effective parameter of these is change in the rib height. The most suitable fluid for the study is TiO2–Cu/EG hybrid nanofluid with 4.0% nanoparticle volume fraction, and the most favorable rib parameters are rib height of h/H = 0.3, rib length of S/H = 1.5 and rib position of X/H = 5.

Similar content being viewed by others

Abbreviations

- \(C_{\text{p}}\) :

-

Specific heat (J kg−1 K−1)

- \(C_{{\upvarepsilon 1}}\), \(C_{{\upvarepsilon 2}}\), \(C_{{\upvarepsilon 3}}\) :

-

Constants for the k-epsilon model

- \(D_{\text{h}}\) :

-

Hydraulic diameter (m)

- \(G_{\text{b}}\) :

-

Production of kinetic energy due to buoyancy

- \(G_{\text{k}}\) :

-

Production of kinetic energy due to mean velocity gradient

- \({ \Pr }_{\text{t}}\) :

-

Turbulent Prandtl number

- \(f_{1} ,\) \(f_{2}\), \(f_{\upmu}\) :

-

Wall damping function

- \(q^{\prime \prime }\) :

-

Heat flux (W m−2)

- \(\bar{u},\bar{v}\) :

-

Time-average x and y-components of velocities, respectively

- EG:

-

Ethylene glycol

- F :

-

Darcy friction factor

- H:

-

Height of the duct (m)

- h/H :

-

Dimensionless rib height

- L :

-

Length of the duct (m)

- Nu:

-

Nusselt number

- nvf:

-

Nanoparticle volume fraction

- P :

-

Pressure (Pa)

- PEC:

-

Performance evaluation criterion

- Re:

-

Reynolds number

- RNG:

-

Renormalized group

- S/H :

-

Dimensionless rib length

- T :

-

Temperature (K)

- x, y :

-

Cartesian coordinates (m)

- X/H :

-

Dimensionless rib position

- \(D\) :

-

Extra term in Eq. (6)

- \(E\) :

-

Roughness parameter

- \(k\) :

-

Turbulent kinetic energy (J)

- \(\delta_{\text{ij}}\) :

-

Kronecker delta

- \(\mu_{\text{t}}\) :

-

Turbulent viscosity (kg m−1 s−1)

- \(\sigma_{\text{k}}\) :

-

Prandtl number for k

- \(\sigma_{\upvarepsilon}\) :

-

Prandtl number for \(\varepsilon\)

- λ :

-

Fluid thermal conductivity (W m−1 K−1)

- \(\varepsilon\) :

-

Dissipation of energy

- \(\mu\) :

-

Dynamic viscosity (kg m−1 s−1)

- \(\rho\) :

-

Density (kg m−3)

- \(\phi\) :

-

Nanoparticle volume fraction

- b :

-

Bulk

- eff:

-

Effective

- enh:

-

Enhanced

- f :

-

Fluid

- hnp:

-

Hybrid nanoparticle

- i, j :

-

Spatial indices

- in:

-

Inlet

- np:

-

Nanoparticle

- w :

-

Wall

References

He W, Toghraie D, Lotfipour A, Pourfattah F, Karimipour A, Afrand M. Effect of twisted-tape inserts and nanofluid on flow field and heat transfer characteristics in a tube. Int Commun Heat Mass Transf. 2020;110:104440.

Kumar KG, Rahimi-Gorji M, Reddy MG, AliJ Chamkha, Alarifi IM. Enhancement of heat transfer in a convergent/divergent channel by using carbon nanotubes in the presence of a Darcy-Forchheimer medium. Microsyst Technol. 2020;26:323–32.

Shashikumar NS, Gireesha BJ, Mahanthesh B, Prasannakumara BC, Chamkha AJ. Entropy generation analysis of magneto-nanoliquids embedded with aluminium and titanium alloy nanoparticles in microchannel with partial slips and convective conditions. Int J Numer Methods Heat Fluid Flow. 2019;29:3638–58.

Chamkha A, Ismael M, Kasaeipoor A, Armaghani T. Entropy Generation and natural convection of CuO-water nanofluid in C-shaped cavity under magnetic field. Entropy. 2016;18:50.

Mohebbi R, Izadi M, Chamkha AJ. Heat source location and natural convection in a C-shaped enclosure saturated by a nanofluid. Phys Fluids. 2017;29:122009.

Dogonchi AS, Armaghani T, Chamkha AJ, Ganji DD. Natural convection analysis in a cavity with an inclined elliptical heater subject to shape factor of nanoparticles and magnetic field. Arab J Sci Eng. 2019;44:7919–31.

Dogonchi AS, Tayebi T, Chamkha AJ, Ganji DD. Natural convection analysis in a square enclosure with a wavy circular heater under magnetic field and nanoparticles. J Therm Anal Calorim. 2020;139:661–71.

Sajid MU, Ali HM, Sufyan A, Rashid D, Zahid SU, Rehman WU. Experimental investigation of TiO2–water nanofluid flow and heat transfer inside wavy mini-channel heat sinks. J Therm Anal Calorim. 2019;137:1279–94.

Ali HM, Babar H, Shah TR, Sajid MU, Qasim MA, Javed S. Preparation techniques of TiO2 nanofluids and challenges: a review. Appl Sci. 2018;8:587.

Sajid MU, Ali HM. Recent advances in application of nanofluids in heat transfer devices: a critical review. Renew Sustain Energy Rev. 2019;103:556–92.

Wahab A, Hassan A, Qasim MA, Ali HM, Babar H, Sajid MU. Solar energy systems: potential of nanofluids. J Mol Liq. 2019;289:111049.

Soudagar MEM, Kalam MA, Sajid MU, Afzal A, Banapurmath NR, Akram N, et al. Thermal analyses of minichannels and use of mathematical and numerical models. Numer Heat Transf Part Appl. 2020;77:497–537.

Babar H, Sajid MU, Ali HM. Viscosity of hybrid nanofluids: a critical review. Therm Sci. 2019;23:1713–54.

Khan MS, Yan M, Ali HM, Amber KP, Bashir MA, Akbar B. Comparative performance assessment of different absorber tube geometries for parabolic trough solar collector using nanofluid. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-09590-2.

Khan MS, Abid M, Ali HM, Amber KP, Bashir MA, Javed S. Comparative performance assessment of solar dish assisted s-CO2 Brayton cycle using nanofluids. Appl Therm Eng. 2019;148:295–306.

Javed S, Ali HM, Babar H, Khan MS, Janjua MM, Bashir MA. Internal convective heat transfer of nanofluids in different flow regimes: a comprehensive review. Phys Stat Mech Appl. https://ideas.repec.org/a/eee/phsmap/v538y2020ics0378437119315791.html.

Khan MS, Amber KP, Ali HM, Abid M, Ratlamwala TAH, Javed S. Performance analysis of solar assisted multigenerational system using therminol VP1 based nanofluids: a comparative study. Therm Sci. 2020;24:865–78.

Promvonge P, Chompookham T, Kwankaomeng S, Thianpong C. Enhanced heat transfer in a triangular ribbed channel with longitudinal vortex generators. Energy Convers Manag. 2010;51:1242–9.

Ma T, Wang Q, Zeng M, Chen Y, Liu Y, Nagarajan V. Study on heat transfer and pressure drop performances of ribbed channel in the high temperature heat exchanger. Appl Energy. 2012;99:393–401.

Liu J, Gao J, Gao T. Forced convection heat transfer of steam in a square ribbed channel. J Mech Sci Technol. 2012;26:1291–8.

Yang Y-T, Tang H-W, Wong C-J. Numerical simulation and optimization of turbulent fluids in a three-dimensional angled ribbed channel. Numer Heat Transf Part Appl. 2016;70:532–45.

Parsazadeh M, Mohammed HA, Fathinia F. Influence of nanofluid on turbulent forced convective flow in a channel with detached rib-arrays. Int Commun Heat Mass Transf. 2013;46:97–105.

Jang HN, Park JS, Kwak JS. Experimental study on heat transfer characteristics in a ribbed channel with dimples, semi-spherical protrusions, or oval protrusions. Appl Therm Eng. 2018;131:734–42.

Omari B, Mataoui A, Salem A. Two-dimensional flow passage through a hot ribbed channel: effect of first rib width. J Therm Sci Eng Appl. https://asmedigitalcollection.asme.org/thermalscienceapplication/article/10/5/051021/448169/Two-Dimensional-Flow-Passage-Through-a-Hot-Ribbed.

Parsaiemehr M, Pourfattah F, Akbari OA, Toghraie D, Sheikhzadeh G. Turbulent flow and heat transfer of water/Al2O3 nanofluid inside a rectangular ribbed channel. Phys E Low Dimens Syst Nanostruct. 2018;96:73–84.

Mayeli P, Hesami H, Besharati-Foumani H, Niajalili M. Al2O3–Water nanofluid heat transfer and entropy generation in a ribbed channel with wavy wall in the presence of magnetic field. Numer Heat Transf Part Appl. 2018;73:604–23.

Shamsi MR, Akbari OA, Marzban A, Toghraie D, Mashayekhi R. Increasing heat transfer of non-Newtonian nanofluid in rectangular microchannel with triangular ribs. Phys E Low Dimens Syst Nanostruct. 2017;93:167–78.

Mohammed HA, Al-Shamani AN, Sheriff JM. Thermal and hydraulic characteristics of turbulent nanofluids flow in a rib–groove channel. Int Commun Heat Mass Transf. 2012;39:1584–94.

Andreozzi A, Manca O, Nardini S, Ricci D. Forced convection enhancement in channels with transversal ribs and nanofluids. Appl Therm Eng. 2016;98:1044–53.

Rahman MRA, Leong KY, Idris AC, Saad MR, Anwar M. Numerical analysis of the forced convective heat transfer on Al2O3–Cu/water hybrid nanofluid. Heat Mass Transf. 2017;53:1835–42.

Tlili I, Bhatti MM, Hamad SM, Barzinjy AA, Sheikholeslami M, Shafee A. Macroscopic modeling for convection of Hybrid nanofluid with magnetic effects. Phys Stat Mech Appl. 2019;534:122136.

Shahsavar A, Godini A, Sardari PT, Toghraie D, Salehipour H. Impact of variable fluid properties on forced convection of Fe3O4/CNT/water hybrid nanofluid in a double-pipe mini-channel heat exchanger. J Therm Anal Calorim. 2019;137:1031–43.

Sajid MU, Ali HM. Thermal conductivity of hybrid nanofluids: a critical review. Int J Heat Mass Transf. 2018;126:211–34.

Nimmagadda R, Venkatasubbaiah K. Conjugate heat transfer analysis of micro-channel using novel hybrid nanofluids (Al2O3 + Ag/water). Eur J Mech B Fluids. 2015;52:19–27.

Leong KY, Razali I, Ku Ahmad KZ, Ong HC, Ghazali MJ, Abdul Rahman MR. Thermal conductivity of an ethylene glycol/water-based nanofluid with copper-titanium dioxide nanoparticles: an experimental approach. Int Commun Heat Mass Transf. 2018;90:23–8.

Hamzah MH, Sidik NAC, Ken TL, Mamat R, Najafi G. Factors affecting the performance of hybrid nanofluids: a comprehensive review. Int J Heat Mass Transf. 2017;115:630–46.

Hayat T, Nadeem S. Heat transfer enhancement with Ag–CuO/water hybrid nanofluid. Results Phys. 2017;7:2317–24.

Moghadassi A, Ghomi E, Parvizian F. A numerical study of water based Al2O3 and Al2O3–Cu hybrid nanofluid effect on forced convective heat transfer. Int J Therm Sci. 2015;92:50–7.

Esfahani NN, Toghraie D, Afrand M. A new correlation for predicting the thermal conductivity of ZnO–Ag (50%–50%)/water hybrid nanofluid: an experimental study. Powder Technol. 2018;323:367–73.

Karimi A, Afrand M. Numerical study on thermal performance of an air-cooled heat exchanger: effects of hybrid nanofluid, pipe arrangement and cross section. Energy Convers Manag. 2018;164:615–28.

Kumar V, Sarkar J. Numerical and experimental investigations on heat transfer and pressure drop characteristics of Al2O3–TiO2 hybrid nanofluid in minichannel heat sink with different mixture ratio. Powder Technol. 2019;345:717–27.

Alipour H, Karimipour A, Safaei MR, Semiromi DT, Akbari OA. Influence of T-semi attached rib on turbulent flow and heat transfer parameters of a silver-water nanofluid with different volume fractions in a three-dimensional trapezoidal microchannel. Phys E Low Dimens Syst Nanostruct. 2017;88:60–76.

Gravndyan Q, Akbari OA, Toghraie D, Marzban A, Mashayekhi R, Karimi R, et al. The effect of aspect ratios of rib on the heat transfer and laminar water/TiO2 nanofluid flow in a two-dimensional rectangular microchannel. J Mol Liq. 2017;236:254–65.

Heydari A, Akbari OA, Safaei MR, Derakhshani M, Alrashed AAAA, Mashayekhi R, et al. The effect of attack angle of triangular ribs on heat transfer of nanofluids in a microchannel. J Therm Anal Calorim. 2018;131:2893–912.

Akbari OA, Toghraie D, Karimipour A. Numerical simulation of heat transfer and turbulent flow of water nanofluids copper oxide in rectangular microchannel with semi-attached rib. Adv Mech Eng. 2016;8:1687814016641016.

Mohebbi R, Izadi M, Amiri Delouei A, Sajjadi H. Effect of MWCNT–Fe3O4/water hybrid nanofluid on the thermal performance of ribbed channel with apart sections of heating and cooling. J Therm Anal Calorim. 2019;135:3029–42.

Abdollahi A, Sharma RN, Mohammed HA, Vatani A. Heat transfer and flow analysis of Al2O3–water nanofluids in interrupted microchannel heat sink with ellipse and diamond ribs in the transverse microchambers. Heat Transf Eng. 2018;39:1461–9.

Kumar S, Kothiyal AD, Bisht MS, Kumar A. Turbulent heat transfer and nanofluid flow in a protruded ribbed square passage. Results Phys. 2017;7:3603–18.

Ahmed HE, Salman BH, Kerbeet A. Heat transfer enhancement of turbulent forced nanofluid flow in a duct using triangular rib. Int J Heat Mass Transf. 2019;134:30–40.

Nasrin R, Parvin S. Investigation of buoyancy-driven flow and heat transfer in a trapezoidal cavity filled with water–Cu nanofluid. Int Commun Heat Mass Transf. 2012;39:270–4.

Pak BC, Cho YI. Hydrodynamic and heat transfer study of dispersed fluids with submicron metallic oxide particles. Exp Heat Transf. 1998;11:151–70.

Xuan Y, Roetzel W. Conceptions for heat transfer correlation of nanofluids. Int J Heat Mass Transf. 2000;43:3701–7.

Brinkman HC. The viscosity of concentrated suspensions and solutions. J Chem Phys. 1952;20:571.

Hamilton RL, Crosser OK. Thermal conductivity of heterogeneous two-component systems. Ind Eng Chem Fundam. 1962;1:187–91.

Tayebi T, Chamkha AJ. Free convection enhancement in an annulus between horizontal confocal elliptical cylinders using hybrid nanofluids. Numer Heat Transf Part Appl. 2016;70:1141–56.

Zhang C, Wang D, Zhu Y, Han Y, Wu J, Peng X. Numerical study on heat transfer and flow characteristics of a tube fitted with double spiral spring. Int J Therm Sci. 2015;94:18–27.

Kumar A, Layek A. Nusselt number and friction factor correlation of solar air heater having twisted-rib roughness on absorber plate. Renew Energy. 2019;130:687–99.

Ponnada S, Subrahmanyam T, Naidu SV. A comparative study on the thermal performance of water in a circular tube with twisted tapes, perforated twisted tapes and perforated twisted tapes with alternate axis. Int J Therm Sci. 2019;136:530–8.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ekiciler, R. Effects of novel hybrid nanofluid (TiO2–Cu/EG) and geometrical parameters of triangular rib mounted in a duct on heat transfer and flow characteristics. J Therm Anal Calorim 143, 1371–1387 (2021). https://doi.org/10.1007/s10973-020-09913-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09913-3