Abstract

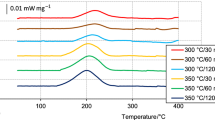

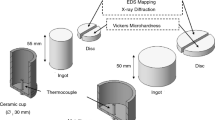

The influence of cold rolling on thermal and mechanical properties together with microstructure observation of cast AlZnMgCu(ScZr) alloys has been investigated. Differential scanning calorimetry measurements and microhardness were compared to microstructure that was observed by microscopy (scanning electron and transmission), electron backscatter and X-ray diffractions. Microstructure observation of all studied alloys proved eutectic phase at (sub)grain boundaries. The eutectic phase at grain boundary in the AlZnMgCuScZr has a disordered quasicrystalline structure (known as the T phase or Mg32(Al,Cu,Zn)49). In the AlZnMgCu alloy, the eutectic phase consists of two phases—predominant MgZn2 phase and minor quasicrystalline T phase. During casting and subsequent cooling, multilayer primary Al3(Sc,Zr) particles also precipitated in the alloy with Sc,Zr addition. Solute clusters and/or Guinier–Preston zones were dissolved during the annealing up to ~ 170 °C in the alloys. The highest hardening is caused by particle formation of metastable η′ and stable η phase in AlZnMgCu system observed at ~ 200 °C. Precipitation of the secondary Al3(Sc,Zr) particles is probably the reason of hardening after annealing above 300 °C in the Sc,Zr-containing alloys. Melting of eutectic phases was observed in DSC curves at temperatures ~ 481 and ~ 493 °C in the studied alloys. Activation energies of the Guinier–Preston zones dissolution and/or solute clusters were calculated using Kissinger and Starink method as QA ≈ 100 kJ mol−1 and the formation of the particles of Al–Zn–Mg–Cu system as QB ≈ 150 kJ mol−1. No significant effect on the calculation of activation energy values of thermal processes was observed in deformed alloys. Sc,Zr addition in the alloys stabilizes grains, and there is no recrystallization in the AlZnMgCuScZr alloy at temperature 450 °C/10 h.

Similar content being viewed by others

References

Toropova LS, Eskin DG, Kharakterova ML, Dobatkina TV. Advanced aluminium alloys containing scandium—structure and properties. Amsterdam: Gordon and Breach Science Publisher; 1998. ISBN 90-5699-089-6.

Dursun T, Soutis C. Recent developments in advanced aircraft aluminium alloys. Mater Des. 2014. https://doi.org/10.1016/j.matdes.2013.12.002.

Vakhromov RO, Antipov VV, Tkachenko EA. Research and development of high-strength of AlZnMgCu alloys. In: ICAA13 13th international conference on aluminium alloys. 2012. https://doi.org/10.1002/9781118495292.ch228.

Rometsch PA, Zhang Y, Khight S. Heat treatment of 7xxx series aluminium alloys—Some recent developments. Trans Nonferrous Met Soc China. 2014. https://doi.org/10.1016/S1003-6326(14)63306-9.

Zhang M, Liu T, He CH, Ding J, Liu E, Shi CH, Li J, Zhao N. Evolution of microstructure and properties of Al–Zn–Mg–Cu–Sc–Zr alloy during aging treatment. J Alloy Compd. 2016. https://doi.org/10.1016/j.jallcom.2015.10.296.

Yang XB, Chen JH, Liu JZ, Qin F, Xie J, Wu CL. A high-strength AlZnMg alloy hardened by the T-phase precipitates. J Alloy Compd. 2014. https://doi.org/10.1016/j.jallcom.2014.04.185.

Feng CH, Shou W, Liu H, Yi D, Feng Y. Microstructure and mechanical properties of high strength Al–Zn–Mg–Cu alloys used for oil drill pipes. Trans Nonferrous Met Soc China. 2015. https://doi.org/10.1016/S1003-6326(15)63994-2.

Gang S, Cerezo A. Early-stage precipitation in Al–Zn–Mg–Cu alloy (7050). Acta Mater. 2004. https://doi.org/10.1016/j.actamat.2004.06.025.

Yang W, Ji S, Wang M, Li Z. Precipitation behaviour of Al–Zn–Mg–Cu alloy and diffraction analysis from η′ precipitates in four variants. J Alloy Compd. 2014. https://doi.org/10.1016/j.jallcom.2014.05.061.

Venkateswarlu K, Pathak LC, Raya AK, Dasa G, Verma PK, Kumar M, Ghosh RN. Microstructure, tensile strength and wear behaviour of Al–Sc alloy. Mater Sci Eng A. 2004. https://doi.org/10.1016/j.msea.2004.05.075.

Zhou S, Zhang Z, Li M, Pan D, Su H, Du X, Li P, Wu Y. Effect of Sc on microstructure and mechanical properties of as-cast Al–Mg alloys. Mater Des. 2016. https://doi.org/10.1016/j.matdes.2015.10.132.

Mostafopoor S, Malekan M, Emamy M. Effects of Zr addition on solidification characteristics of Al–Zn–Mg–Cu alloy using thermal analysis. J Thermal Anal Calorim. 2018. https://doi.org/10.1007/s10973-018-7426-1.

Vlach M, Čížek J, Smola B, Melikhova O, Vlček M, Kodetová V, Kudrnová H, Hruška P. Heat treatment and age hardening of Al–Si–Mg–Mn commercial alloy with addition of Sc and Zr. Mater Charact. 2017. https://doi.org/10.1016/j.matchar.2017.04.017.

Vlach M, Stulíková I, Smola B, Císařová H, Piešová J, Daniš S, Gemma R, Málek J, Tanprayoon D, Neubert V. Phase transformations in non-isothermally annealed as-cast and cold-rolled AlMnScZr alloys. Int J Mater Res. 2012. https://doi.org/10.3139/146.110712.

Shi Y, Pan Q, Li M, Huang X, Li B. Effect of Sc and Zr additions on corrosion behaviour of Al–Zn–Mg–Cu alloys. J Alloy Compd. 2014. https://doi.org/10.1016/j.jmst.2016.12.003.

Yin ZM, Pan QL, Zhang YH, Jiang F. Effect of minor Sc and Zr on the microstructure and mechanical properties of Al–Mg based alloys. Mater Sci Eng, A. 2000. https://doi.org/10.1016/S0921-5093(99)00682-6.

Zhang WG, Ye YC, He LJ, Li PJ, Feng X, Novikov LS. Dynamic response and microstructure control of Al–Sc binary alloy under high-speed impact. Mater Sci Eng, A. 2013. https://doi.org/10.1016/j.msea.2013.04.067.

Costa S, Puga H, Barbosa J, Pinto AMP. The effect of Sc additions on the microstructure and age hardening behaviour of as cast Al–Sc alloys. Mater Des. 2012. https://doi.org/10.1016/j.matdes.2012.06.019.

Davydov VG, Rostova TD, Zakharov VV, Filatov YA, Yelagin VI. Scientific principles of making an alloying addition of scandium to aluminium alloys. Mater Sci Eng, A. 2000. https://doi.org/10.1016/S0921-5093(99)00652-8.

Kaiser MS, Datta S, Roychowdhury A, Banerjee MK. Effect of scandium on the microstructure and ageing behaviour of cast Al–6Mg alloy. Mater Charact. 2008. https://doi.org/10.1016/j.matchar.2008.03.006.

Norman AF, Prangnell PB, McEwen RS. The solidification behaviour of dilute aluminium–scandium alloys. Acta Mater. 1988. https://doi.org/10.1016/S1359-6454(98)00257-2.

Hyde KB, Norman AF, Prangnell PB. The effect of cooling rate on the morphology of primary Al3Sc intermetallic particles in Al–Sc alloys. Acta Mater. 2001. https://doi.org/10.1016/S1359-6454(01)00050-7.

Zhou S, Zhang Z, Li M, Pan D, Su H, Du X, Li P, Wu Y. Correlative characterization of primary particles formed in as-cast Al–Mg–Alloy containing a high level of Sc. Mater Charact. 2016. https://doi.org/10.1016/j.matchar.2016.05.011.

Vlach M, Čížek J, Smola B, Stulíková I, Hruška P, Kodetová V, Daniš S, Tanprayoon D, Neubert V. Influence of dislocations on precipitation processes in hot-extruded Al–Mn–Sc–Zr alloy. Int J Mater Res. 2018. https://doi.org/10.3139/146.111654.

Vlach M, Stulíková I, Smola B, Kekule T, Kudrnová H, Kodetová V, Očenášek V, Málek J, Neubert V. Annealing effects in hot-deformed Al–Mn–Sc–Zr alloys. Kov Mat. 2015. https://doi.org/10.4149/km_2015_5_295.

Montagné P, Tillard M. On the adaptability of 1/1 cubic approximant structure in the Mg–Al–Zn system with the particular example of Mg32Al12Zn37. J Alloy Compd. 2016. https://doi.org/10.1016/j.jallcom.2015.09.201.

Wang F, Eskin D, Connoley T, Mi J. Influence of ultrasonic treatment on formation of primary Al3Zr in Al – 0.4Zr alloy. Trans Nonferrous Met Soc China. 2017. https://doi.org/10.1016/s1003-6326(17)60115-8.

Li JH, Wiessner M, Albu M, Wurster S, Sartory B, Hofer F, Schumacher P. Correlative characterization of primary Al3(Sc, Zr) phase in an Al–Zn–Mg based alloy. Mater Charact. 2015. https://doi.org/10.1016/j.matchar.2015.01.018.

Olafsson P, Sandstrom R, Karlsson AJ. Comparison of experimental, calculated and observed values for electrical and thermal conductivity of aluminium alloys. J Mater Sci. 1997. https://doi.org/10.1023/A:1018680024876.

Ghosh KS, Gao N, Starink MJ. Characterization of high-pressure torsion processed 7150 Al–Zn–Mg–Cu alloy. Mater Sci Eng, A. 2012. https://doi.org/10.1016/j.msea.2012.05.026.

Ghosh KS, Gao N. Determination of kinetic parameters from calorimetric study of solid-state reactions in 7150 Al–Zn–Mg alloy. Trans Nonferrous Met Soc China. 2011. https://doi.org/10.1016/S1003-6326(11)60843-1.

Antonione C, Marino F, Riontino G, Abis S, Russo E. An evaluation of AA 7012 microstructure by differential scanning calorimetry. Mater Chem Phys. 1988. https://doi.org/10.1016/0254-0584(88)90055-7.

Abis S, Riontino G. A resistivity study of 7012 Al-Mg-Zn alloy commercial tempers. Mater Lett. 1987;5(11–12):442. https://doi.org/10.1016/0167-577X(87)90060-7

Starink MJ. The determination of activation energy from linear heating rate experiments: a comparison of the accuracy of isoconversion methods. Thermochim Acta. 2003. https://doi.org/10.1016/S0040-6031(03)00144-8.

Vlach M, Čížek J, Kodetová V, Kekule T, Lukáč F, Cieslar M, Kudrnová H, Bajtošová L, Leibner M, Harcuba P, Málek J, Neubert V. Annealing effects in cast commercial aluminium Al–Zn–Mg–Cu(–Sc–Zr) allolys. Met Mater Int. 2019. https://doi.org/10.1007/s12540-019-00499-6.

Chemingui M, Ameur R, Optasanu V, Khitouni M. DSC analysis of phase transformations during precipitation hardening in Al–Zn–Mg alloy (7072). J Thermal Anal Calorim. 2019. https://doi.org/10.1007/s10973-018-7856-9.

Werenskiold JC, Deschamps A, Bréchet Y. Characterization and modeling of precipitation kinetics in an Al–Zn–Mg alloy. Mat Sci Eng A. 2000. https://doi.org/10.1016/S0921-5093(00)01247-8.

Emani S, Benedyk J, Nash P, Chen D. Double aging and thermomechanical heat treatment of AA7075 aluminium alloy extrusions. Mater Sci. 2009. https://doi.org/10.1007/s10853-009-3879-8.

Vlach M, Kodetová V, Smola B, Čížek J, Kekule T, Cieslar M, Kudrnová H, Bajtošová L, Leibner M, Procházka I. Characterization of phase development in commercial Al–Zn–Mg(–Mn, Fe) alloy with and without Sc Zr-addition. Kov Mat. 2018. https://doi.org/10.4149/km_2018_6_367.

Jerina L, Medved J, Godec M, Vončina M. Influence of tge specific surface area of secondary material on the solidification process and microstructure of aluminium alloy AA7075. J Therm Anal Calorim. 2018. https://doi.org/10.1007/s10973-018-7425-2.

Starink MJ. Comments on “Precipitation kinetics of Al–1.12Mg2Si–0.35Si and Al–1.07Mg2Si–0.33Cu alloys”. J Alloy Compd. 2007. https://doi.org/10.1016/j.jallcom.2006.06.069.

Kodetová V, Vlach M, Smola B, Kekule T, Daniš S, Kudrnová H, Málek J. Effect of cold rolling on precipitation processes in Al–Zn–Mg(–Sc–Zr) alloy. Acta Phys Pol A. 2018. https://doi.org/10.12693/aphyspola.134.631.

Liang Z. Clustering and precipitation in Al–Mg–Si alloys. Dissertation. Institut für Angewandte Materialforschung. November 2012. ISSN: 1868–5781. https://doi.org/10.5442/d0032.

Lang P, Wojcik T, Povoden-Karadeniz E, Falaha A, Kozeschnik E. Thermo-kinetic prediction of metastable and stable phase precipitation in Al–Zn–Mg series aluminium alloys during non-isothermal DSC analysis. J Alloy Compd. 2014. https://doi.org/10.1016/j.jallcom.2014.04.119.

Tang J, Chen H, Zhang X, Liu X, Liu W, Ouyang H, Li H. Influence of quench-induced precipitation on aging behaviour of Al–Zn–Mg–Cu alloy. Trans Nonfer Met Soc China. 2012. https://doi.org/10.1016/S1003-6326(11)61313-7.

Chemingui M, Ameur R, Optasanu V, Khitouni M. DSC analysis of phase transformations during precipitation hardening in Al–Zn–Mg alloy (7020). J Therm Anal Calorim. 2018. https://doi.org/10.1007/s10973-018-7856-9.

Afify N, Gaber A, Abbady G. Fine scale precipitates in Al–Mg–Zn alloys after various aging temperatures. Mater Sci Appl. 2011. https://doi.org/10.4236/msa.2011.25056.

Kodetová V, Vlach M, Smola B, Málek J, Kekule T, Kudrnová H. Response of as-cast Al–Zn–Mg alloy with and without Sc, Zr-addition to annealing with constant heating rate. IN: Proceedings Paper—26th international conference on metallurgy and materials, Tanger. 2017. ISBN: 978-80-87294-79-6. WOS: 000434346900285.

Acknowledgements

This work was supported by The Czech Science Foundation (GACR, Project No. 17-17139S). VK acknowledges support by the project SVV-2017-260449 (Specific Academic Research Projects). PH acknowledges financial support by ERDF under the project CZ.02.1.01/0.0/0.0/15_003/0000485. The authors are also grateful to Ivana Stulíková and Tamara Čučková for their help.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kodetová, V., Vlach, M., Kudrnová, H. et al. Phase transformations in commercial cold-rolled Al–Zn–Mg–Cu alloys with Sc and Zr addition. J Therm Anal Calorim 145, 2991–3002 (2021). https://doi.org/10.1007/s10973-020-09862-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09862-x