Abstract

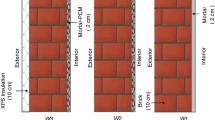

In this work, thermal performance of a conventional brick incorporating phase change material (PCM) is studied. The influence of brick containing PCM on heating and cooling loads is examined considering different fusion temperatures, locations and quantities of PCM. Seasonal and annual thermal performance analysis of brick filled with PCM is evaluated and quantified for climatic conditions of Marmara region, Turkey, by an established and verified numerical model. The obtained results are compared with those of conventional brick and brick filled with phase stabilized material to identify the contribution of latent heat to energy saving. The results showed that filling the gaps of brick near the indoor ambient provides a higher energy conservation. The optimum fusion temperature of PCM varied from season to season in the range of 18–26 °C. An adverse effect of the latent heat activation was observed in summer season, causing higher cooling energy demand by an inappropriate selection of phase transition temperature. Then, an annual analysis was performed to determine the optimum melting temperature which was found to be 18 °C. By incorporating PCM to the brick, the annual thermal load decreased by 17.6%, 13.2% of which was attained due to the utilization of latent heat. The outcomes of this study suggest that the integration of PCM with optimum fusion temperature into the brick can reduce heating and cooling loads considerably in every season of the year and provide thermal comfort for the occupants.

Similar content being viewed by others

Abbreviations

- C p :

-

Specific heat (J kg−1 K−1)

- E :

-

Energy saving (kJ m−2 year−1)

- F :

-

View factor

- f :

-

Liquid fraction

- g :

-

Gravitational acceleration (m s−2)

- h :

-

Convective heat transfer coefficient (W m−2 K−1)

- H :

-

Height (m)

- I :

-

Solar radiation (W m−2)

- k :

-

Thermal conductivity (W m−1 K−1)

- L c :

-

Characteristic length (m)

- L H :

-

Latent heat (kJ kg−1)

- Nu:

-

Nusselt number

- P :

-

One day period (86,400 s)

- Pr:

-

Prandtl number

- Q :

-

Total heat gain/loss (kJ m−2 day−1)

- Ra:

-

Rayleigh number

- T :

-

Temperature (K, °C)

- t :

-

Time (s, h)

- w :

-

Wind velocity (m s−1)

- W :

-

Width (m)

- α :

-

Thermal diffusivity (m2 s−1)

- α G :

-

Absorptivity

- β :

-

Thermal expansion coefficient (K−1)

- ε :

-

Emissivity

- φ :

-

A factor for radiative heat exchange

- γ :

-

Kinematic viscosity (m2 s−1)

- ρ :

-

Density (kg m−3)

- ϑ :

-

Tilt angle

- σ :

-

Stefan–Boltzmann constant (5.67 × 10−8 W m−2 K−4)

- air:

-

Air

- c:

-

Cold

- E:

-

Energy saving

- ex:

-

External surface

- f:

-

Fusion

- ground:

-

Ground

- h:

-

Hot

- in:

-

Indoor

- o:

-

Outdoor

- PCM:

-

Phase change material

- PSM:

-

Phase stabilized material

- Reference:

-

Reference

- s:

-

Surface (interior)

- sky:

-

Sky

- Total:

-

Total

References

"Energy Efficiency 2018—Analysis and Outlooks to 2040," International Energy Agency Publications, France, 2018.

Qiu G, Sun J, Nie L, Ma Y, Cai W, Shen C. Theoretical study on heat transfer characteristics of a finned tube used in the collector/evaporator under solar radiation. Appl Therm Eng. 2020;165:114564.

Qiu G, Sun J, Ma Y, Qu J, Cai W. Theoretical study on the heat transfer characteristics of a plain fin in the finned-tube evaporator assisted by solar energy. Int J Heat Mass Transf. 2018;127:847–55.

Sarbu I, Sebarchievici C. A comprehensive review of thermal energy storage. Sustainability. 2018;42(2):395–415.

Du K, Calautit J, Wang Z, Wu Y, Liu H. A review of the applications of phase change materials in cooling, heating and power generation in different temperature ranges. Appl Energy. 2018;220:242–73.

Fang GY, Wu SM, Liu X. Experimental study on cool storage air-conditioning system with spherical capsules packed bed. Energy Build. 2010;42:1056–62.

Parameshwaran R, Kalaiselvam S. Energy conservative air conditioning system using silver nano-based PCM thermal storage for modern buildings. Energy Build. 2014;69:202–12.

Schossig P, Henning HM, Gschwander S, Haussmann T. Micro-encapsulated phase-change materials integrated into construction materials. Sol Energy Mater Solar Cells. 2005;89(2–3):297–306.

Pasupathy A, Athanasius L, Velraj R, Seeniraj RV. Experimental investigation and numerical simulation analysis on the thermal performance of a building roof incorporating phase change material (PCM) for thermal management. Appl Therm Eng. 2008;28:556–65.

Li D, Wu Y, Zhang G, Arıcı M, Liu C, Wang F. Influence of glazed roof containing phase change material on indoor thermal environment and energy consumption. Appl Energy. 2018;222:343–50.

Royon L, Karim L, Bontemps A. Optimization of PCM embedded in a floor panel developed for thermal management of the lightweight envelope of buildings. Energy Build. 2014;82:385–90.

Huang KL, Feng GH, Zhang JS. Experimental and numerical study on phase change material floor in solar water heating system with a new design. Sol Energy. 2014;105:126–38.

Liu H, Awbi HB. Performance of phase change material boards under natural convection. Build Environ. 2009;44(9):1788–93.

Zhou Y, Zheng S, Chen H, Zhang G. Thermal performance and optimized thickness of active shape-stabilized PCM boards for side-wall cooling and under-floor heating system. Indoor Built Environ. 2016;25(8):1279–98.

Liu C, Zhang G, Arıcı M, Bian J, Li D. Thermal performance of non-ventilated multilayer glazing facades filled with phase change material. Sol Energy. 2019;177:464–70.

Li D, Wu Y, Liu C, Zhang G, Arıcı M. Energy investigation of glazed windows containing Nano-PCM in different seasons. Energy Convers Manag. 2018;172:119–28.

Baetens R, Jelle BP, Gustavsen A. Phase change materials for building applications: a state-of-the-art review. Energy Build. 2010;42(9):1361–8.

Sharma RK, Ganesan P, Tyagi VV. Long-term thermal and chemical reliability study of different organic phase change materials for thermal energy storage applications. J Therm Anal Calorim. 2016;124(3):1357–66.

Sharma A, Tyagi VV, Chen CR, Buddhi D. Review on thermal energy storage with phase change. Renew Sustain Energy Rev. 2009;13(2):318–45.

Liu Z, Yu Z, Yang T, Qin D, Li S, Zhang G, Haghighat F, Joybari MM. A review on macro-encapsulated phase change material for building envelope applications. Build Environ. 2018;144:281–94.

Neeper DA. Thermal dynamics of wallboard with latent heat storage. Sol Energy. 2000;68(5):393–403.

Cabeza LF, Castelló C, Nogués M, Medrano M, Leppers R, Zubillaga O. Use of microencapsulated PCM in concrete walls for energy savings. Energy Build. 2007;39(2):113–9.

Lu S, Experimental study of phase change wall room in Winter in China. In: The 2005 World sustainable building conference, Tokyo, 2005.

Arıcı M, Bilgin F, Nižetić S, Karabay H. PCM integrated to external building walls: an optimization study on maximum activation of latent heat. Appl Therm Eng. 2019;165:114560. https://doi.org/10.1016/j.applthermaleng.2019.114560.

Zhang Y, Lin K, Jiang Y, Zhou G. Thermal storage and nonlinear heat-transfer characteristics of PCM wallboard. Energy Build. 2008;40:1771–9.

Kuznik F, Virgone J, Roux J-J. Energetic efficiency of room wall containing PCM wallboard: a full-scale experimental investigation. Energy Build. 2008;40:148–56.

Jin X, Shi D, Medina MA, Shi X, Zhou X, Zhang X. Optimal location of PCM layer in building walls under Nanjing (China) weather conditions. J Therm Anal Calorim. 2017;129:1767–78.

Izquierdo-Barrientos M, Belmonte J, Rodríguez-Sánchez D, Molina A, Almendros-Ibáñez J. A numerical study of external building walls containing phase change materials (PCM). Appl Therm Eng. 2012;47:73–85.

Zwanzig SD, Lian Y, Brehob EG. Numerical simulation of phase change material composite wallboard in a multi-layered building envelope. Energy Convers Manag. 2013;69:27–40.

Mengjie S, Fuxin N, Ning M, Yanxin H, Shiming D. Review on building energy performance improvement using phase change materials. Energy Build. 2018;158:776–93.

Kuznik F, David D, Johannes K, Roux J-J. A review on phase change materials integrated in building walls. Renew Sustain Energy Rev. 2011;15(1):379–91.

Jeon J, Lee J-H, Seo J, Jeong S-G, Kim S. Application of PCM thermal energy storage system to reduce building energy consumption. J Therm Anal Calorim. 2013;111:279–88.

Li D, Wu Y, Wang B, Liu C, Arıcı M. Optical and thermal performance of glazing units containing PCM in buildings: a review. Constr Build Mater. 2020;233:117327.

Alawadhi EM. Thermal analysis of a building brick containing phase change material. Energy Build. 2008;40:351–7.

Hichem N, Noureddine S, Nadia S, Djamila D. Experimental and numerical study of a usual brick filled with PCM to improve the thermal inertia of buildings. Energy Proc. 2013;36:766–75.

Vicente R, Silva T. Brick masonry walls with PCM macrocapsules: an experimental approach. Appl Therm Eng. 2014;67:24–34.

Kant K, Shukla A, Sharma A. Heat transfer studies of building brick containing phase change materials. Sol Energy. 2017;155:1233–42.

Zhang C, Chen Y, Wu L, Shi M. Thermal response of brick wall filled with phase change materials (PCM) under fluctuating outdoor temperatures. Energy Build. 2011;43:3514–20.

Aketouane Z, Malha M, Bruneau D, Bah A, Michel B, Asbik M, Ansari O. Energy savings potential by integrating phase change material into hollow bricks: the case of Moroccan buildings. Build Simul. 2018;11(6):1109–22.

Mazzeo D, Oliveti G, Arcuri N. Definition of a new set of parameters for the dynamic thermal characterization of PCM layers in the presence of one or more liquid-solid interfaces. Energy Build. 2017;141(15):379–96.

"The Turkish State Meteorological Affairs General Directorate (DMI)," 2017.

"Photovoltaic Geographical Information System," [Online]. https://re.jrc.ec.europa.eu/pvg_tools/en/tools.html#HR. Accessed 15 Aug 2019.

Castell A, Farid MM. Experimental validation of a methodology to assess PCM effectiveness in cooling building envelopes passively. Energy Build. 2014;81:59–71.

McAdams WH. Heat transmission. New York: McGraw-Hill; 1954.

Zivkovic B, Fujii I. An analysis of isothermal phase change of phase change material within rectangular and cylindrical containers. Sol Energy. 2001;70(1):51–61.

Alawadhi EM. Phase change process with free convection in a circular enclosure: numerical simulations. Comput Fluids. 2004;33:1335–488.

Çengel YA. Heat transfer a practical approach. New York: McGraw-Hill; 2002.

Caton I. Natural convection in enclosures. In: Proceedings of the 6th international heat transfer conference, vol. 6; 1978. p. 13–43.

Brano VL, Ciulla G, Piacentino A, Cardona F. Finite difference thermal model of a latent heat storage system coupled with a photovoltaic device: description and experimental validation. Renew Energy. 2014;68:181–93.

Souayfane F, Biwole PH, Fardoun F. Thermal behavior of a translucent superinsulated latent heat energy storage wall in summertime. Appl Energy. 2018;217:390–408.

Swinbank WC. Long-wave radiation from clear skies. Q J R Meteorol Soc. 1963;89(381):339–48.

Smith CJ, Forster PM, Crook R. Global analysis of photovoltaic energy output enhanced by phase change material cooling. Appl Energy. 2014;126:21–8.

Fadl M, Eames PC. An experimental investigations of the melting of RT44HC inside a horizontal rectangular test cell subject to uniform wall heat flux. Int J Heat Mass Transf. 2019;140:731–42.

Acknowledgements

The authors acknowledge the meteorological data provided by The Turkish State Meteorological Service.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tunçbilek, E., Arıcı, M., Bouadila, S. et al. Seasonal and annual performance analysis of PCM-integrated building brick under the climatic conditions of Marmara region. J Therm Anal Calorim 141, 613–624 (2020). https://doi.org/10.1007/s10973-020-09320-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09320-8