Abstract

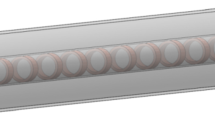

The heat exchanger pipe diameter has a significant effect on the flow characteristics as well as on the initial investment, operation and overall cost. Increasing fin dimensions increases the annulus hydraulic diameters. Even though the total volume of the heat exchanger remains unchanged between the finned and bare designs, the heat duty increases with increased heat transfer area for the finned design. The fins should be designed, and the dimensions should be calculated with special attention for different flow rates and heat exchanger dimensions. In this study, number, geometry and dimensions of the fins are determined using the algorithms available in the literature. The operational condition optimization is carried out accompanied with the cost analysis. In addition, the effects of the types of working fluids and fouled and clean cases are investigated for the total heat transfer enhancement in parallel with performance, lifetime and cost issues. A detailed analysis is presented for finned and unfinned double-pipe heat exchanger models for pure engine oil and its nanofluid mixtures with Ti, TiO2, Cu, CuO, Al and Al2O3 nanoparticles, multi-wall carbon nanotubes and graphene nanosheet having a constant particle concentration in the liquid phase. The nanofluid is flowing in annulus side, whereas the seawater is flowing in the tube side. It is observed that both the pressure drop and the pumping power increase with the increasing fin number and decrease with the cleanliness factor, whereas the total tube number decreases with increasing fin number. It is found that different types of nanofluids affect the cost and optimum annulus side velocity significantly. The results are summarized in several figures that consider the increasing Reynolds number with the cleanliness factor, the heat transfer coefficient and the pressure drop, the friction factor with changing mass flow rate and the cost values with corresponding annulus side velocities. Finally, the overall characteristics of the trend lines are provided in the figures.

Similar content being viewed by others

Abbreviations

- A :

-

Heat transfer surface area, m2

- A c :

-

Net free flow area, m2

- C :

-

Pipe element price, USD

- CF:

-

Cleanliness factor

- c p :

-

Specific heat at constant pressure, J kg−1 K−1

- d :

-

Diameter, m

- d e :

-

Equivalent diameter for heat transfer, m

- d h :

-

Hydraulic diameter for pressure drop, m

- f :

-

Friction factor

- h :

-

Convective heat transfer coefficient, W m−2 K−1

- H f :

-

Height of the fin, m

- k :

-

Thermal conductivity, W m−1 K−1

- L :

-

Tube length, m

- m :

-

Fin parameter in Eq. (27)

- \(\dot{m}\) :

-

Mass flow rate, kg s−1

- n :

-

Number of tubes

- N f :

-

Number of fins per tube

- N t :

-

Number of tubes in one leg of heat exchanger

- Nu:

-

Nusselt number

- P :

-

Pumping power, W

- Pr:

-

Prandtl number

- P w :

-

Wetted perimeter for pressure drop, m

- P h :

-

Wetted perimeter for heat transfer, m

- \(\dot{Q}\) :

-

Heat rejection duty, W

- R I :

-

Fouling resistance for tube side, m2 W−1 °C−1

- R fo :

-

Fouling resistance for annulus side, m2 W−1 °C−1

- Re:

-

Reynolds number

- s :

- T :

-

Temperature

- T w :

-

Wall temperature

- U :

-

Overall heat transfer coefficient based on total external surface area, W m−2 K−1

- w :

-

Flow velocity, m s−1

- ΔP :

-

Pressure drop, Pa

- ΔT :

-

Temperature difference, K

- Δ:

-

Fin thickness, m

- \(\eta_{\text{f}}\) :

-

Fin efficiency, %

- \(\eta_{\text{o}}\) :

-

Overall efficiency, %

- \(\eta_{\text{p}}\) :

-

Pump efficiency, %

- θ y :

-

Amortization period, year

- θ h :

-

Operating period, hour

- μ :

-

Dynamic viscosity, Pa s

- ρ :

-

Mass density, kg m−3

- Φ:

-

Particle concentration, %

- c:

-

Cross section

- e:

-

Equivalent

- el:

-

Electric

- f:

-

Fluid

- h:

-

Hydraulic

- i:

-

Inside

- in:

-

Inlet

- m:

-

Momentum

- nf:

-

Nanofluid

- o:

-

Outside, overall

- oc:

-

Clean conditions

- of:

-

Fouled conditions

- ord:

-

Ordinal number

- out:

-

Outlet

- p:

-

Parallel

- pa:

-

Particle

- t:

-

Total

- tb:

-

Tube

- u:

-

Unfinned

- w:

-

Wall, wetted

- 1:

-

Tube side, investment

- 2:

-

Annulus side, operating

References

Dizaji HS, Jafarmadar S, Mobadersani F. Experimental studies on heat transfer and pressure drop characteristics for new arrangements of corrugated tubes in a double pipe heat exchanger. Int J Therm Sci. 2015;96:211–20. https://doi.org/10.1016/j.ijthermalsci.2015.05.009.

Prasad PD, Gupta AVSSKS, Deepak K. Investigation of trapezoidal-cut twisted tape insert in a double pipe U-tube heat exchanger using Al2O3/water nanofluid. Procedia Mater Sci. 2015;10:50–63. https://doi.org/10.1016/j.mspro.2015.06.025.

Hasanpour A, Farhadi M, Sedighi K. Experimental heat transfer and pressure drop study on typical, perforated, V-cut and U-cut twisted tapes in a helically corrugated heat exchanger. Int Commun Heat Mass Transfer. 2016;71:126–36. https://doi.org/10.1016/j.icheatmasstransfer.2015.12.032.

Sheikholeslami M, Gorji-Bandpy M, Ganji DD. Experimental study on turbulent flow and heat transfer in an air to water heat exchanger using perforated circular-ring. Exp Thermal Fluid Sci. 2016;70:185–95. https://doi.org/10.1016/j.expthermflusci.2015.09.002.

Cavazzuti M, Agnani E, Corticelli MA. Optimization of a finned concentric pipes heat exchanger for industrial recuperative burners. Appl Therm Eng. 2015;84:110–7. https://doi.org/10.1016/j.applthermaleng.2015.03.027.

Iqbal Z, Syed KS, Ishaq M. Fin design for conjugate heat transfer optimization in double pipe. Int J Therm Sci. 2015;94:242–58. https://doi.org/10.1016/j.ijthermalsci.2015.03.011.

Syed KS, Ishaq M, Iqbal Z, Hassan A. Numerical study of an innovative design of a finned double-pipe heat exchanger with variable fin-tip thickness. Energy Convers Manag. 2015;98:69–80. https://doi.org/10.1016/j.enconman.2015.03.038.

Ahmad W, Syed KS, Ishaq M, Hassan A, Iqbal Z. Numerical study of conjugate heat transfer in a double-pipe with exponential fins using DGFEM. Appl Therm Eng. 2017;111:1184–201. https://doi.org/10.1016/j.applthermaleng.2016.09.171.

Han HZ, Li BX, Wu H, Shao W. Multi-objective shape optimization of double pipe heat exchanger with inner corrugated tube using RSM method. Int J Therm Sci. 2015;90:173–86. https://doi.org/10.1016/j.ijthermalsci.2014.12.010.

Hashemian M, Jafarmadar S, Dizaji HS. A comprehensive numerical study on multi-criteria design analyses in a novel form (conical) of double pipe heat exchanger. Appl Therm Eng. 2016;102:1228–37. https://doi.org/10.1016/j.applthermaleng.2016.04.057.

Shirvan KM, Ellahi R, Mirzakhanlari S, Mamourian M. Enhancement of heat transfer and heat exchanger effectiveness in a double pipe heat exchanger filled with porous media: numerical simulation and sensitivity analysis of turbulent fluid flow. Appl Therm Eng. 2016;109:761–74. https://doi.org/10.1016/j.applthermaleng.2016.08.116.

Vaezi S, Karbalaee S, Hanafizadeh P. Effect of aspect ratio on heat transfer enhancement in alternating oval double pipe heat exchangers. Appl Therm Eng. 2017;125:1164–72. https://doi.org/10.1016/j.applthermaleng.2017.07.070.

Chavda NK. Effect of nanofluid on heat transfer characteristics of double pipe heat exchanger: part-II: effect of copper oxide nanofluid. Int J Res Eng Technol. 2015;4(4):688–97.

Sarafraz MM, Hormozi F. Intensification of forced convection heat transfer using biological nanofluid in a double-pipe heat exchanger. Exp Thermal Fluid Sci. 2015;66:279–89. https://doi.org/10.1016/j.expthermflusci.2015.03.028.

Zohir AE, Aziz AAA, Habib MA. Heat transfer characteristics and pressure drop of the concentric tube equipped with coiled wires for pulsating turbulent flow. Exp Thermal Fluid Sci. 2015;65:41–51. https://doi.org/10.1016/j.expthermflusci.2015.03.003.

El-Maghlany WM, Hanafy AA, Hassan AA, El-Magid MA. Experimental study of Cu–water nanofluid heat transfer and pressure drop in a horizontal double-tube heat exchanger. Exp Thermal Fluid Sci. 2016;78:100–11. https://doi.org/10.1016/j.expthermflusci.2016.05.015.

Goodarzi M, Kherbeet AS, Afrand M, Sadeghinezhad E, Mehrali M, Zahedi P, Wongwises S, Dahari M. Investigation of heat transfer performance and friction factor of a counter-flow double-pipe heat exchanger using nitrogen-doped, graphene-based nanofluids. Int Commun Heat Mass Transfer. 2016;76:16–23. https://doi.org/10.1016/j.icheatmasstransfer.2016.05.018.

Pourahmad S, Pesteei SM. Effectiveness-NTU analyses in a double tube heat exchanger equipped with wavy strip considering various angles. Energy Convers Manag. 2016;123:462–9. https://doi.org/10.1016/j.enconman.2016.06.063.

Mousavi SV, Sheikholeslami M, Gerdroodbary MB. The influence of magnetic field on heat transfer of magnetic nanofluid in a sinusoidal double pipe heat exchanger. Chem Eng Res Des. 2016;113:112–24. https://doi.org/10.1016/j.cherd.2016.07.009.

Saeedan M, Nazar ARS, Abbasi Y, Karimi R. CFD investigation and neutral network modeling of heat transfer and pressure drop of nanofluids in double pipe helically baffled heat exchanger with a 3-D fined tube. Appl Therm Eng. 2016;100:721–9. https://doi.org/10.1016/j.applthermaleng.2016.01.125.

Alhusseny A, Turan A, Nasser A. Rotating metal foam structures for performance enhancement of double-pipe heat exchangers. Int J Heat Mass Transf. 2017;105:124–39. https://doi.org/10.1016/j.ijheatmasstransfer.2016.09.055.

Sumathi BAL, Vijay K. CFD analysis on double pipe hair-pin heat exchanger with different nano fluids. IJITR. 2017;5(3):6471–6.

Khan A, Ali HM, Nazir R, Ali R, Munir A, Ahmad B, Ahmad Z. Experimental investigation of enhanced heat transfer of a car radiator using ZnO nanoparticles in H2O–ethylene glycol mixture. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08320-7).

Hosseini SM, Safaei MR, Estellé P, Jafarnia SH. Heat transfer of water-based carbon nanotube nanofluids in the shell and tube cooling heat exchangers of the gasoline product of the residue fluid catalytic cracking unit. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08813-5.

Arzani HK, Amiri A, Arzani HK, Rozali SB, Kazi SN, Badarudin A. Toward improved heat transfer performance of annular heat exchangers with water/ethylene glycol-based nanofluids containing graphene nanoplatelets. J Therm Anal Calorim. 2016;126(3):1427–36. https://doi.org/10.1007/s10973-018-7240-9.

Moghaddaszadeh N, Esfahani JA, Mahian O. Performance enhancement of heat exchangers using eccentric tape inserts and nanofluids. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08009-x.

Dalkilic AS, Acikgoz Ö, Gumus MA, Wongwises S. Determination of optimum velocity for various nanofluids flowing in a double-pipe heat exchanger. Heat Transfer Eng. 2016;38:11–25. https://doi.org/10.1080/01457632.2016.1151302.

Kayacı N, Balcılar M, Tabatabaei M, Celen A, Yıldız O, Dalkılıç AS, Wongwises S. Determination of the single-phase forced convection heat transfer characteristics of TiO2 nano fluids flowing in smooth and micro-fin tubes by means of CFD and ANN analyses. Curr Nanosci. 2013;9:61–80. https://doi.org/10.2174/157341313805118036.

Kakac S, Liu H, Pramaunjaroenkij A. Heat exchangers selection, rating, and thermal design. 3rd ed. 2012. ISBN-13: 978-1-4200-5374-6.

Taborek J. Double-pipe and multi-tube heat exchangers with plain and longitudinal Finned Tubes. Heat Transf Eng. 1997;2:34–45. https://doi.org/10.1080/01457639708939894.

Celen A, Kayaci N, Çebi A, Demir H, Dalkılıç AS, Wongwises S. Numerical investigation for the calculation of TiO2–water nanofluids’ pressure drop in plain and enhanced pipes. Int Commun Heat Mass Transfer. 2014;53:98–108. https://doi.org/10.1016/j.icheatmasstransfer.2014.02.022.

Bhattacharya P, Saha KS, Yadav A, Phelani EP, Prasher SR. Brownian dynamics simulation to determine the effective thermal conductivity of nanofluids. J Appl Phys. 2004;95:6492–4. https://doi.org/10.1063/1.1736319.

Pak CB, Cho IY. Hydrodynamic and heat transfer study of dispersed fluids with submicron metallic oxide particles. A J Therm Energy Gener Transp Storage Conv Exp Heat Transf. 1998;11:151–70. https://doi.org/10.1080/08916159808946559.

Maiga SEB, Palm SJ, Nguyen CT, Roy G, Galanis N. Heat transfer enhancement by using nanofluids in forced convection flows. Int J Heat Fluid Flow. 2005;26(4):530–46. https://doi.org/10.1016/j.ijheatfluidflow.2005.02.004.

Xuan Y, Roetzel W. Conceptions for heat transfer correlation of nanofluids. Int J Heat Mass Transf. 2000;43:3701–7. https://doi.org/10.1016/S0017-9310(99)00369-5.

Genceli OF. Heat exchangers. İstanbul: Birsen Yayınevi; 2017. ISBN:978-975-511-218-9.

Petukhov BS. Heat transfer and friction in turbulent pipe flow with variable physical properties. Adv Heat Transf. 1970;6:503–64. https://doi.org/10.1016/S0065-2717(08)70153-9.

Incropera FP, DeWitt DP, Bergman TL, Lavine AS. Fundamentals of heat and mass transfer. 6th ed. Wiley; 2008, ISBN-13: 978-0471457282.

Dalkılıç AS, Küçükyıldırım BO, Akdoğan Eker A, Yıldız F, Akpınar A, Jumpholkul C, Wongwises S. Effects of sonication time on the stability and viscosity of functionalized MWCNT-based nanolubricants. Curr Nanosci. 2020;16. (Article in Press). https://doi.org/10.1016/j.icheatmasstransfer.2016.09.021.

Dalkilic AS, Mahian O, Kucukyildirim BO, Eker AA, Ozturk TH, Jumpholkul C, Wongwises S. Experimental study on the stability and viscosity for the blends of functionalized MWCNTs with refrigeration compressor oils. Curr Nanosci. 2018;14(3):216–26. https://doi.org/10.2174/1573413713666171109154924.

Duangthongsuk W, Yiamsawasd T, Selim Dalkilic A, Wongwises S. Pool-boiling heat transfer characteristics of Al2O3-water nanofluids on a horizontal cylindrical heating surface. Curr Nanosci. 2013;9(1):56–60. https://doi.org/10.2174/157341313805117956.

Yiamsawasd T, Selim Dalkilic A, Wongwises S. Measurement of specific heat of nanofluids. Curr Nanosci. 2012;8(6):939–44. https://doi.org/10.2174/157341312803989132.

Duangthongsuk W, Selim Dalkilic A, Wongwises S. Convective heat transfer of Al2O3-water nanofluids in a microchannel heat sink. Curr Nanosci. 2012;8(3):317–22. https://doi.org/10.2174/157341312800620368.

Monfared M, Shahsavar A, Bahrebar MR. Second law analysis of turbulent convection flow of boehmite alumina nanofluid inside a double-pipe heat exchanger considering various shapes for nanoparticle. J Therm Anal Calorim. 2019;135(2):1521–32. https://doi.org/10.1007/s10973-018-7708-7.

Acknowledgements

The fourth author acknowledges the financial support provided by the “Research Chair Grant” National Science and Technology Development Agency (NSTDA), the Thailand Research Fund (TRF) and King Mongkut’s University of Technology Thonburi through the ‘‘KMUTT 55th Anniversary Commemorative Fund.”

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dalkılıç, A.S., Mercan, H., Özçelik, G. et al. Optimization of the finned double-pipe heat exchanger using nanofluids as working fluids. J Therm Anal Calorim 143, 859–878 (2021). https://doi.org/10.1007/s10973-020-09290-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09290-x