Abstract

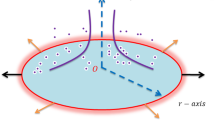

The explanation of abnormal enhancement of transported energy in colloidal nanoparticles in a liquid has sparked much interest in recent years. The complexity comes from the inter-particle phenomenon and cluster formation. The process of nanoparticle aggregation, which is caused by convective phenomena and particle-to-particle interaction energy in a flow, is investigated in this research. Therefore, the probability of collision and cohesion among clusters is modelled, as stated in this research. ANSYS-Fluent 17 CFD tools are employed to implement a new method of nanoparticle aggregation, new essential forces, new heat law and cluster drag coefficient. The importance of the interaction forces is compared to drag force, and essential forces are considered in coupling between nanoparticles and fluid flow. An important parameter is defined for the surface energy density regarding the attractive energy between the double layer and surrounding fluid to capture the cohesion of particles. Particles’ random migration is also presented through their angular and radial displacement. The analyses for interactions show the significance of Brownian motion in both particles’ migration and coupling effects in the fluid. However, nanoparticles are pushed away from walls due to repulsive forces, and Brownian motion is found to be effective mainly on angular displacement around the tube centreline. The attractive energy is found to be dominant when two clusters are at an equal distance. Hence, the cluster formation in convective regions should be taken into account for modelling purposes. A higher concentrated region also occurs midway between the centreline and the heated wall.

Similar content being viewed by others

Abbreviations

- \(A\) :

-

Hamaker constant (J)

- \(A_{\text{p}}\) :

-

Particle surface area (m2)

- \(A_{\text{pp}}\) :

-

Particle projected area (m2)

- \(C_{\text{c}}\) :

-

Cunningham correction factor

- \(C_{\text{D}}\) :

-

Drag coefficient

- \(C_{\text{ML}}\) :

-

Rotational coefficient

- \(C_{\upomega}\) :

-

Rotational drag coefficient

- \(c_{\text{p}}\) :

-

Specific heat (J kg−1 K−1)

- \(d_{\text{p}}\) :

-

Particle diameter (m)

- \(D_{\text{T}}\) :

-

Thermophoresis coefficient

- \(f_{{{\text{B}}_{\text{i}} }}\) :

-

Brownian force (N kg−1)

- \(f_{\text{s}}\) :

-

Interaction forces (N m−3)

- \(f_{\text{d}}\) :

-

Drag function

- \(G_{\text{w}}\) :

-

Gaussian weight function

- h :

-

Particle–particle distance (m)

- \(I_{\text{p}}\) :

-

Moment of inertia (kg m−2)

- \(k\) :

-

Thermal conductivity (W m−1 K−1)

- \(K_{\text{B}}\) :

-

Boltzmann constant (m2 kg K−1 s−2)

- \(m_{\text{p}}^{{}}\) :

-

Particle mass (kg)

- \(\dot{m}_{\text{p}}^{{}}\) :

-

Particle mass flow rate (kg s−1)

- \(N_{\text{particle}}\) :

-

Number of particles in the parcel

- \(n\) :

-

Possible number of collision

- P :

-

Poisson distribution

- \(Re_{\text{p}}\) :

-

Particle Reynolds number

- \(S_{\text{h}}\) :

-

Thermal interaction between particles and fluid (W m−3)

- \(\Delta t_{\text{p}}\) :

-

Particle time step (s)

- U 1, U 2 :

-

Uniform random number

- \(u_{\text{p}}\) :

-

Particle velocity (m s−1)

- \(u_{\text{s}}\) :

-

Particle–fluid relative velocity (m s−1)

- V EDL :

-

Electric double-layer energy (J)

- V vdw :

-

van der Waals energy (J)

- x :

-

Location (m)

- \(\Delta x\) :

-

Characteristic length of the cell

- \(We\) :

-

Webber number

- \(\varepsilon_{0}\) :

-

Vacuum permittivity (CV−1 m−1)

- \(\varepsilon {}_{\text{r}}\) :

-

Relative permittivity

- \(\kappa\) :

-

Debye–Huckel parameter (m−1)

- \(\gamma\) :

-

Surface energy density (J m−2)

- \(\dot{\gamma }\) :

-

Shear rate (1/s)

- \({\varvec{\upomega}}_{\text{p}}\) :

-

Particle angular velocity (1/s)

- \({\varvec{\Omega}}\) :

-

Relative particle–liquid angular velocity (1/s)

- \(\psi\) :

-

Potential on the surface of particle (V)

- \(\theta_{\text{particle}}\) :

-

Particle variable in the node

- \(\bar{\theta }_{\text{parcel}}\) :

-

Particle variables affected by nodes in the neighbourhood

- \(\tau\) :

-

Particle relaxation time (s)

- \(\overset{\lower0.5em\hbox{$\smash{\scriptscriptstyle\rightharpoonup}$}} {\zeta }\) :

-

Random function

- \(\chi\) :

-

Random number between 0 and 1

References

Estellé P, Mahian O, Maré T, Öztop HF. Natural convection of CNT water-based nanofluids in a differentially heated square cavity. J Therm Anal Calorim. 2017;128:1765–70.

Rashidi S, Mahian O, Languri EM. Applications of nanofluids in condensing and evaporating systems. J Therm Anal Calorim. 2018;131:2027–39.

Meibodi SS, Kianifar A, Mahian O, Wongwises S. Second law analysis of a nanofluid-based solar collector using experimental data. J Therm Anal Calorim. 2016;126:617–25.

Aberoumand S, Jafarimoghaddam A. Mixed convection heat transfer of nanofluids inside curved tubes: an experimental study. Appl Therm Eng. 2016;108:967–79.

Xiao B, Yang Y, Chen L. Developing a novel form of thermal conductivity of nanofluids with Brownian motion effect by means of fractal geometry. Powder Technol. 2013;239:409–14.

He Y, Men Y, Zhao Y, Lu H, Ding Y. Numerical investigation into the convective heat transfer of TiO2 nanofluids flowing through a straight tube under the laminar flow conditions. Appl Therm Eng. 2009;29:1965–72.

Esfe MH, Saedodin S, Bahiraei M, Toghraie D, Mahian O, Wongwises S. Thermal conductivity modeling of MgO/EG nanofluids using experimental data and artificial neural network. J Therm Anal Calorim. 2014;118:287–94.

Esfe MH, Saedodin S, Mahian O, Wongwises S. Thermal conductivity of Al2O3/water nanofluids: measurement, correlation, sensitivity analysis, and comparisons with literature reports. J Therm Anal Calorim. 2014;117:675–81.

Yu W, France DM, Timofeeva EV, Singh D, Routbort JL. Thermophysical property-related comparison criteria for nanofluid heat transfer enhancement in turbulent flow. Appl Phys Lett. 2010;96:13–6.

Aybar HŞ, Sharifpur M, Azizian MR, Mehrabi M, Meyer JP. A review of thermal conductivity models for nanofluids. Heat Transf Eng. 2014;36:1085–110.

Hwang KS, Jang SP, Choi SUS. Flow and convective heat transfer characteristics of water-based Al2O3 nanofluids in fully developed laminar flow regime. Int J Heat Mass Transf. 2009;52:193–9.

Bianco V, Chiacchio F, Manca O, Nardini S. Numerical investigation of nanofluids forced convection in circular tubes. Appl Therm Eng. 2009;29:3632–42.

Kumar N, Puranik BP. Numerical study of convective heat transfer with nanofluids in turbulent flow using a Lagrangian-Eulerian approach. Appl Therm Eng. 2017;111:1674–81.

Rashidi S, Bovand M, Esfahani JA, Ahmadi G. Discrete particle model for convective Al2O3–water nanofluid around a triangular obstacle. Appl Therm Eng. 2016;100:39–54.

Tahir S, Mital M. Numerical investigation of laminar nanofluid developing flow and heat transfer in a circular channel. Appl Therm Eng. 2012;39:8–14.

Krishnamurthy S, Bhattacharya P, Phelan PE, Prasher RS. Enhanced mass transport in nanofluids. Nano Lett. 2006;6:419–23.

Ganguly S, Sarkar S, Kumar Hota T, Mishra M. Thermally developing combined electroosmotic and pressure-driven flow of nanofluids in a microchannel under the effect of magnetic field. Chem Eng Sci. 2015;126:10–21.

Gupta A, Kumar R. Role of Brownian motion on the thermal conductivity enhancement of nanofluids. Appl Phys Lett. 2007;91:223102.

Gharagozloo PE, Eaton JK, Goodson KE. Diffusion, aggregation, and the thermal conductivity of nanofluids. Appl Phys Lett. 2008;93:2006–9.

Veilleux J, Coulombe S. A dispersion model of enhanced mass diffusion in nanofluids. Chem Eng Sci. 2011;66:2377–84.

Putnam SA, Cahill DG. Transport of nanoscale latex spheres in a temperature gradient. Langmuir. 2005;21:5317–23.

Eslamian M, Saghir MZ. On thermophoresis modeling in inert nanofluids. Int J Therm Sci. 2014;80:58–64.

McNab GS, Meisen A. Thermophoresis in liquids. J Colloid Interface Sci. 1973;44:339–46.

Talbot L, Cheng RK, Schefer RW, Willis DR. Thermophoresis of particles in a heated boundary layer. J Fluid Mech. 1980;101:737–58.

Koo J, Kleinstreuer C. Laminar nanofluid flow in microheat-sinks. Int J Heat Mass Transf. 2005;48:2652–61.

Vladkov M, Barrat JL. Modeling transient absorption and thermal conductivity in a simple nanofluid. Nano Lett. 2006;6:1224–9.

Gao JW, Zheng RT, Ohtani H, Zhu DS, Chen G. Experimental investigation of heat conduction mechanisms in nanofluids. Clue on clustering. Nano Lett. 2009;9:4128–32.

Babaei H, Keblinski P, Khodadadi JM. A proof for insignificant effect of Brownian motion-induced micro-convection on thermal conductivity of nanofluids by utilizing molecular dynamics simulations. J Appl Phys. 2013;113:084302.

Laín S, Sommerfeld M. Numerical calculation of pneumatic conveying in horizontal channels and pipes: detailed analysis of conveying behaviour. Int J Multiph Flow. 2012;39:105–20.

Ozturk S, Hassan YA, Ugaz VM. Interfacial complexation explains anomalous diffusion in nanofluids. Nano Lett. 2010;10:665–71.

Kumar R, Milanova D. Effect of surface tension on nanotube nanofluids. Appl Phys Lett. 2009;94:073107.

Mokhtari Moghari R, Akbarinia A, Shariat M, Talebi F, Laur R. Two phase mixed convection Al2O3–water nanofluid flow in an annulus. Int J Multiph Flow. 2011;37:585–95.

Yang C, Peng K, Nakayama A, Qiu T. Forced convective transport of alumina–water nano fluid in micro-channels subject to constant heat flux. Chem Eng Sci. 2016;152:311–22.

Zhang H, Shao S, Xu H, Tian C. Heat transfer and flow features of Al2O3–water nanofluids flowing through a circular microchannel—experimental results and correlations. Appl Therm Eng. 2013;61:86–92.

Oesterle B, Dinh TB. Experiments on the lift of a spinning sphere in a range of intermediate Reynolds numbers. Exp Fluids. 1998;25:16–22.

Li A, Ahmadi G. Dispersion and deposition of spherical particles from point sources in a turbulent channel flow. Aerosol Sci Technol. 1992;16:209–26.

Zhao B, Chen C, Lai ACK. Lagrangian stochastic particle tracking: further discussion. Aerosol Sci Technol. 2011;45:901–2.

Box GEP, Muller ME, et al. A note on the generation of random normal deviates. Ann Math Stat. 1958;29:610–1.

Marshall JS, Li S. Adhesive particle flow. Cambridge: Cambridge University Press; 2014.

Israelachvili JN. Intermolecular and surface forces: revised. 3rd ed. Cambridge: Academic Press; 2011.

Zheng X, Silber-Li Z. The influence of Saffman lift force on nanoparticle concentration distribution near a wall. Appl Phys Lett. 2009;95:24–7.

Haider A, Levenspiel O. Drag coefficient and terminal velocity of spherical and nonspherical particles. Powder Technol. 1989;58:63–70.

Michaelides EE, Feng Z. Heat transfer from a rigid sphere in a nonuniform flow and temperature field. Int J Heat Mass Transf. 1994;37:2069–76.

O’Rourke PJ. Collective drop effects on vaporizing liquid sprays. Los Alamos Natl Lab, NM. Technical report; 1981.

Bhuiyan MHU, Saidur R, Amalina MA, Mostafizur RM, Islam A. Effect of nanoparticles concentration and their sizes on surface tension of nanofluids. Proc Eng. 2015;105:431–7.

Chinnam J, Das DK, Vajjha RS, Satti JR. Measurements of the surface tension of nanofluids and development of a new correlation. Int J Therm Sci. 2015;98:68–80.

Van Oss CJ, Chaudhury MK, Good RJ. Interfacial Lifshitz-van der Waals and polar interactions in macroscopic systems. Chem Rev. 1988;88:927–41.

Apte SV, Mahesh K, Lundgren T. Accounting for finite-size effects in simulations of disperse particle-laden flows. Int J Multiph Flow. 2008;34:260–71.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Mahdavi, M., Sharifpur, M., Ahmadi, M.H. et al. Aggregation study of Brownian nanoparticles in convective phenomena. J Therm Anal Calorim 135, 111–121 (2019). https://doi.org/10.1007/s10973-018-7283-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7283-y