Abstract

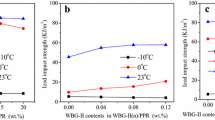

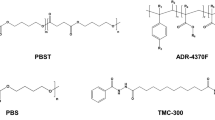

In order to improve processing performance and mechanical properties, chain extension is commercially employed for poly (ethylene terephthalate) (PET). Poly (phenyl methylene isocyanate) (PMDI) with multi-reactive isocyanate groups (–NCO) is a qualified chain extender. However, the introduction of such compound impairs the crystallization properties of PET. Nucleating agent Surlyn® possesses good dispersion in PET, and it is commonly used to improve the crystallization rate of PET. The results showed that the intrinsic viscosity of PPET, representing PET chain-extended by 1.4 mass% PMDI, was enhanced from 0.60 dL g−1 of PET to 1.10 dL g−1. Surlyn significantly improved the crystallization rate of PET. The half crystallization time (t1/2) was decreased from 2.32 min of PPET to 0.74 min of SPPET, standing for PET blended with 1.4 mass% PMDI and 1.2 mass% Surlyn. Consequently, PMDI combined with Surlyn synergistically improved the comprehensive mechanical properties of PET, especially the notched impact strength from 29.2 J m−1 of PET to 45.2 J m−1 of SPPET.

Similar content being viewed by others

References

Awaja F, Pavel D. Recycling of PET. Eur Polym J. 2005;41:1453–77.

Zhang YJ, Zhang C, Li HQ, Du ZJ, Li CJ. Chain extension of poly (ethylene terephthalate) with bisphenol-A dicyanate. J Appl Polym Sci. 2010;117:2003–8.

Tan ZY, Liu SC, Cui XL, Zhang HX. Application of macromolecular chain extender and contribution to the toughening of poly (ethylene terephthalate). J Therm Compos Mater. 2014;29:833–49.

Xia T, Xi ZH, Liu T, Pan X, Fan CY, Zhao L. Melt foamability of reactive extrusion-modified poly (ethylene terephthalate) with pyromellitic dianhydride using supercritical carbon dioxide as blowing agent. Polym Eng Sci. 2015;55:1528–35.

Japon S, Boogh L, Leterrier Y, Manson JAE. Reactive processing of poly (ethylene terephthalate) modified with multifunctional epoxy-based additives. Polymer. 2000;41:5809–18.

Bikiaris DN, Karayannidis GP. Calorimetric study of diepoxide chain-extended poly (ethylene terephthalate). J Therm Anal Calorim. 1998;54:721–9.

Torres N, Robin JJ, Boutevin B. Chemical modification of virgin and recycled poly (ethylene terephthalate) by adding of chain extenders during processing. J Appl Polym Sci. 2001;79:1816–24.

Tang XW, Guo WH, Yin GR, Li BY, Wu CF. Reactive extrusion of recycled poly (ethylene terephthalate) with polycarbonate by addition of chain extender. J Appl Polym Sci. 2007;104:2602–7.

Awaja F, Daver F, Kosior E, Cser F. The effect of chain extension on the thermal behaviour and crystallinity of reactive extruded recycled PET. J Therm Anal Calorim. 2004;104:865–84.

Nascimento CR, Azuma C, Bretas RR, Farah M, Dias ML. Chain extension reaction in solid-state polymerization of recycled PET: the influence of 2,2′-bis-2-oxazoline and pyromellitic anhydride. J Appl Polym Sci. 2010;115:3177–88.

Raffa P, Coltelli MB, Savi S, Bianchi S, Castelvetro V. Chain extension and branching of poly (ethylene terephthalate) (PET) with di- and multifunctional epoxy or isocyanate additives: an experimental and modelling study. React Funct Polym. 2012;72:50–60.

Agabekov V, Golubovich V, Pesetskii S. Effect of nanodisperse carbon fillers and isocyanate chain extender on structure and properties of poly (ethylene terephthalate). J Nanomater. 2012;2012:1–7.

Wang GL, Chen YH. Isothermal crystallization and spherulite morphology of poly (ethylene terephthalate)/Na+-MMT nanocomposites prepared through solidstate mechanochemical method. J Therm Anal Calorim. 2017. https://doi.org/10.1007/s10973-017-6857-4.

Kim MW, Lee SH, Youn JR. Effects of filler size and content on shrinkage and gloss of injection molded PBT/PET/talc composites. Polym Compos. 2009;31:1020–7.

Lee SJ, Hahm WG, Kikutani T, Kim BC. Effects of clay and POSS nanoparticles on the quiescent and shear-induced crystallization behavior of high molecular weight poly (ethylene terephthalate). Polym Eng Sci. 2009;49:317–23.

Gao W, Wang Z, Zhao Z, Ding L, Zhu Y. Effect of barium sulfate on thermal stability and crystallization properties of poly (ethylene terephthalate). J Therm Anal Calorim. 2017;129:1047–55.

Jiang XL, Luo SJ, Sun K, Chen XD. Effect of nucleating agents on crystallization kinetics of PET. Express Polym Lett. 2007;1:245–51.

Yu Y, Yu YL, Jin MN, Bu HS. Nucleation mechanism and crystallization behavior of poly (ethylene terephthalate) containing ionomers. Macromol Chem Phys. 2000;201:1894–900.

Yu Y, Bu HS. Crystallization behavior of poly (ethylene terephthalate) modified by ionomers. Macromol Chem Phys. 2001;202:421–5.

Tang SD, Xin Z. Strucural effects of ionomers on the morphology, isothermal crystallization kinetics and melting behavior of PET/ionomers. Polymer. 2009;50:1054–61.

Calcagno CIW, Mariani CM, Teixeira SR, Mauler RS. The effect of organic modifier of the clay on morphology and crystallization properties of PET nanocomposites. Polymer. 2007;48:966–74.

Wu TB, Ke YC. Preparation of silica–PS composite particles and their application in PET. Eur Polym J. 2006;42:274–85.

Mekhilef N, Kadi AA, Ajji A. Blends of modified polycarbonate and high density polyethylene. Polym Eng Sci. 1992;32:894–902.

Gui QD, Xin Z, Zhu WP, Dai GC. Effects of an organic phosphorus nucleating agent on crystallization behaviors and mechanical properties of poly(propylene). J Appl Polym Sci. 2003;88:297–301.

Talbott MF, Springer GS, Berglund LA. The effects of crystallinity on the mechanical properties of PEEK polymer and graphite fiber reinforced PEEK. J Compos Mater. 1987;21:1056–81.

Nagendra N, Ramamurty U, Goh TT, Li Y. Effect of crystallinity on the impact toughness of a La-based bulk metallic glass. Acta Mater. 2000;48:2603–15.

Wang XD, Cui XG. Effect of ionomers on mechanical properties, morphology, and rheology of polyoxymethylene and its blends with methyl methacrylate–styrene–butadiene copolymer. Eur Polym J. 2005;41:871–80.

Ma YL, Yang GP, Xie LS. Morphology, nonisothermal crystallization behavior and mechanical properties of polypropylene modified by ionomers. J Macromol Sci B. 2014;53:1829–45.

Acknowledgements

We gratefully acknowledge the support from the projects for Academician workstation of Guangdong (2015B090904001) and Dongguan.

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Liu, Y., Wirasaputra, A., Jiang, Z. et al. Fabrication of improved overall properties of poly (ethylene terephthalate) by simultaneous chain extension and crystallization promotion. J Therm Anal Calorim 133, 1447–1454 (2018). https://doi.org/10.1007/s10973-018-7179-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7179-x