Abstract

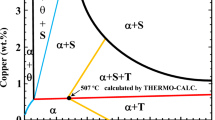

A non-commercial Al4Cu0.5Mg alloy has been used for investigating the effects of the elemental Sn additions. Uniaxial die compaction response of the alloys in terms of green density was examined, and the results showed that Sn addition has no effect when compacting conducted under high pressures. In total, 93–95% green density was achieved with an applied pressure of 400 MPa. Thermal events occurring during the sintering of the emerging alloys were studied by using differential scanning calorimetry (DSC). First thermal event on the DSC analysis of the Al4Cu0.5Mg1Sn alloy is the melting of elemental Sn, whereas for Al4Cu0.5Mg alloy, it is the formation of Al–Mg liquid nearly at 450 °C. Also it is clearly seen on the DSC analysis that Sn addition led to an increase in the formation enthalpy of Al–Mg liquid phase. High Sn content and high sintering temperature (620 °C), therefore high liquid-phase content, caused decrease on the mechanical properties due to thick intergranular phases and grain coarsening. Highest transverse rupture strength and hardness values were obtained from Al4Cu0.5Mg0.1Sn alloy sintered at 600 °C and measured as 390 MPa and 73 HB, respectively.

Similar content being viewed by others

References

Eisen WB, Ferguson BL, German RM, Iacocca R, Lee PW, Madan D, et al. Powder metal technologies and applications. Novelty: ASM International; 1998.

Capus JM. Metal powders: a global survey of production, applications and markets 2001–2010; 2005. https://books.google.com.tr/books?id=m61iY9mslPYC.

Miller W, Zhuang L, Bottema J, Wittebrood A, De Smet P, Haszler A, et al. Recent development in aluminium alloys for the automotive industry. Mater Sci Eng A. 2000;280:37–49. https://doi.org/10.1016/S0921-5093(99)00653-X.

Friedrich H, Schumann S. Research for a “new age of magnesium” in the automotive industry. J Mater Process Technol. 2001;117:276–81.

Mostafapoor S, Malekan M, Emamy M. Thermal analysis study on the grain refinement of Al–15Zn–2.5Mg–2.5Cu alloy. J Therm Anal Calorim. 2017;127:1941–52. https://doi.org/10.1007/s10973-016-5737-7.

Schaffer GB. Powder processed aluminium alloys. Mater Forum. 2004;28:65–74.

Qian M, Schaffer GB. Sintering of aluminium and its alloys. Sinter. Adv. Mater. Fundam. Process. 2010. https://doi.org/10.1533/9781845699949.3.291.

Hirosawa S, Sato T, Kamio A, Flower HM. Classification of the role of microalloying elements in phase decomposition of Al based alloys. Acta Mater. 2000;48:1797–806.

Sercombe T, Schaffer G. The effect of trace elements on the sintering of Al–Cu alloys. Acta Mater. 1999;47:689–97.

Schaffer GB, Huo SH, Drennan J, Auchterlonie GJ. The effect of trace elements on the sintering of an Al–Zn–Mg–Cu alloy. Acta Mater. 2001;49:2671–8. https://doi.org/10.1016/S1359-6454(01)00177-X.

Sercombe TB, Schaffer GB. On the use of trace additions of Sn to enhance sintered 2xxx series Al powder alloys. Mater Sci Eng A. 1999;268:32–9.

Banerjee S, Robi PS, Srinivasan A, Lakavath PK. Effect of trace additions of Sn on microstructure and mechanical properties of Al–Cu–Mg alloys. Mater Des. 2010;31:4007–15. https://doi.org/10.1016/j.matdes.2010.03.012.

Sercombe TB. On the sintering of uncompacted, pre-alloyed Al powder alloys. Mater Sci Eng A. 2003;341:163–8. https://doi.org/10.1016/S0921-5093(02)00207-1.

Ruiz-Navas EM, Delgado ML, Gordo E. Tin influence on sintering of prealloyed and premixed Al–Cu powders. In: Proceedings of World Powder Metallurgy Congress and Exhibition, World PM 2010. Florence: European Powder Metallurgy Association (EPMA); 2010. p. 118–28.

Kondoh K, Kimura A, Takeda Y, Watanabe R. Behavior of magnesium and tin at the surface of aluminum–silicon–magnesium–tin alloy powder particles at elevated temperature and their effect on direct nitriding reaction. J Jpn Inst Met. 2000;64:1106–12. https://doi.org/10.2320/jinstmet1952.64.11_1106.

Momeni H, Razavi H, Shabestari SG. Effect of supersolidus liquid phase sintering on the microstructure and densification of the Al–Cu–Mg pre-alloyed powder. Iran J Mater Sci Eng. 2011;8:10–7.

Gökçe A, Findik F, Kurt AO. Sintering and aging behaviours of Al4CuXMg PM alloy. Can Metall Q. 2016;55:391–401. https://doi.org/10.1080/00084433.2016.1237604.

German RM. Particle size influence on the strength relation for air sintered aluminum. Metall Trans A. 1975;6:1964–5. https://doi.org/10.1007/BF02646866.

Padmavathi C, Upadhyaya A. Sintering behaviour and mechanical properties of Al–Cu–Mg–Si–Sn aluminum alloy. Trans Indian Inst Met. 2011;64:345–57. https://doi.org/10.1007/s12666-011-0089-2.

Gökçe A, Findik F, Kurt AO. Microstructural examination and properties of premixed Al–Cu–Mg powder metallurgy alloy. Mater Charact. 2011;62:730–5.

Dieter GE, Bacon DJ. Mechanical metallurgy. New York: McGraw-Hill; 1986.

Boland CD, Paul Bishop D, Hexemer RL, Donaldson IW. Development of an aluminum PM alloy for “press-sinter-size” technology. Int J Powder Metall. 2011;47:39–48.

Ibrahim A, Bishop DP, Kipouros GJ. Sinterability and characterization of commercial aluminum powder metallurgy alloy Alumix 321. Powder Technol. 2015;279:106–12. https://doi.org/10.1016/j.powtec.2015.04.001.

Schaffer GB, Sercombe TB, Lumley RN. Liquid phase sintering of aluminium alloys. Mater Chem Phys. 2001;67:85–91. https://doi.org/10.1016/S0254-0584(00)00424-7.

Mondolfo LF. Al–Mg aluminum–magnesium system BT—aluminum alloys. London: Butterworth-Heinemann; 1976.

Gökçe A, Findik F, Kurt AO. Effects of sintering temperature and time on the properties of Al–Cu PM alloy. Pract Metallogr. 2017;54:533–51. https://doi.org/10.3139/147.110461.

Zhao J, Yuan Y, Cui F. Relationship between the Cu content and thermal properties of Al–Cu alloys for latent heat energy storage. J Therm Anal Calorim. 2017;129:109–15. https://doi.org/10.1007/s10973-017-6153-3.

MacAskill IA, Hexemer RL, Donaldson IW, Bishop DP. Effects of magnesium, tin and nitrogen on the sintering response of aluminum powder. J Mater Process Technol. 2010;210:2252–60. https://doi.org/10.1016/j.jmatprotec.2010.08.018.

Jose MM, Francisco C. Sintering response and microstructural evolution of an Al–Cu–Mg–Si premix. Int J Powder Metall. 2007;43:59–69.

Gökçe A, Findik F, Kurt AO. Effects of Mg content on aging behavior of Al4CuXMg PM alloy. Mater Des. 2013;46:524–31. https://doi.org/10.1016/j.matdes.2012.10.045.

Dudas JH, Thompson CB. Improved sintering procedures for aluminum P/M parts BT—modern developments in powder metallurgy: volume 5: materials and properties. In: Hausner HH, editor. Proceedings of the 1970 international powder metallurgy conference, sponsored by the Metal Power Industries Federation. Boston, MA: Springer; 1971. p. 19–36. https://doi.org/10.1007/978-1-4615-8963-1_2.

Feng W, Baiqing X, Yongan Z, Zhihui L, Peiyue L. Microstructural characterization of an Al–Cu–Mg alloy containing Fe and Ni. J Alloys Compd. 2009;487:445–9.

Moreau ED, Donaldson IW, Hexemer RL, Bishop DP. Effects of Fe and Ni additions on emerging Al—part 2—influence of elevated temperature exposure. Can Metall Q. 2013;52:380–90. https://doi.org/10.1179/1879139513Y.0000000072.

Li J-G, Chatain D, Coudurier L, Eustathopoulos N. Wettability of sapphire by Sn–Al alloys. J Mater Sci Lett. 1988;7:961–3. https://doi.org/10.1007/BF00720742.

Cooke RW, Hexemer RL, Donaldson IW, Bishop DP. Dispersoid strengthening of Al–Cu–Mg P/M alloy utilising transition metal additions. Powder Metall. 2012;55:191–9. https://doi.org/10.1179/1743290111y.0000000012.

Rao CS, Upadhyaya GS. 2014 and 6061 aluminium alloy-based powder metallurgy composites containing silicon carbide particles/fibres. Mater Des. 1995;16:359–66.

Acknowledgements

The authors would like to acknowledge the financial assistance from The Scientific and Technological Research Council of Turkey via Undergraduate Students Research Projects Funding Program (2209/A)—Project Number: 1919B011501050.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Özay, Ç., Gencer, E.B. & Gökçe, A. Microstructural properties of sintered Al–Cu–Mg–Sn alloys. J Therm Anal Calorim 134, 23–33 (2018). https://doi.org/10.1007/s10973-018-7171-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7171-5